Snorkel TB100J User Manual

Page 68

10. DAILY INSPECTION & MAINTENANCE

10 - 9

P/N 0112478

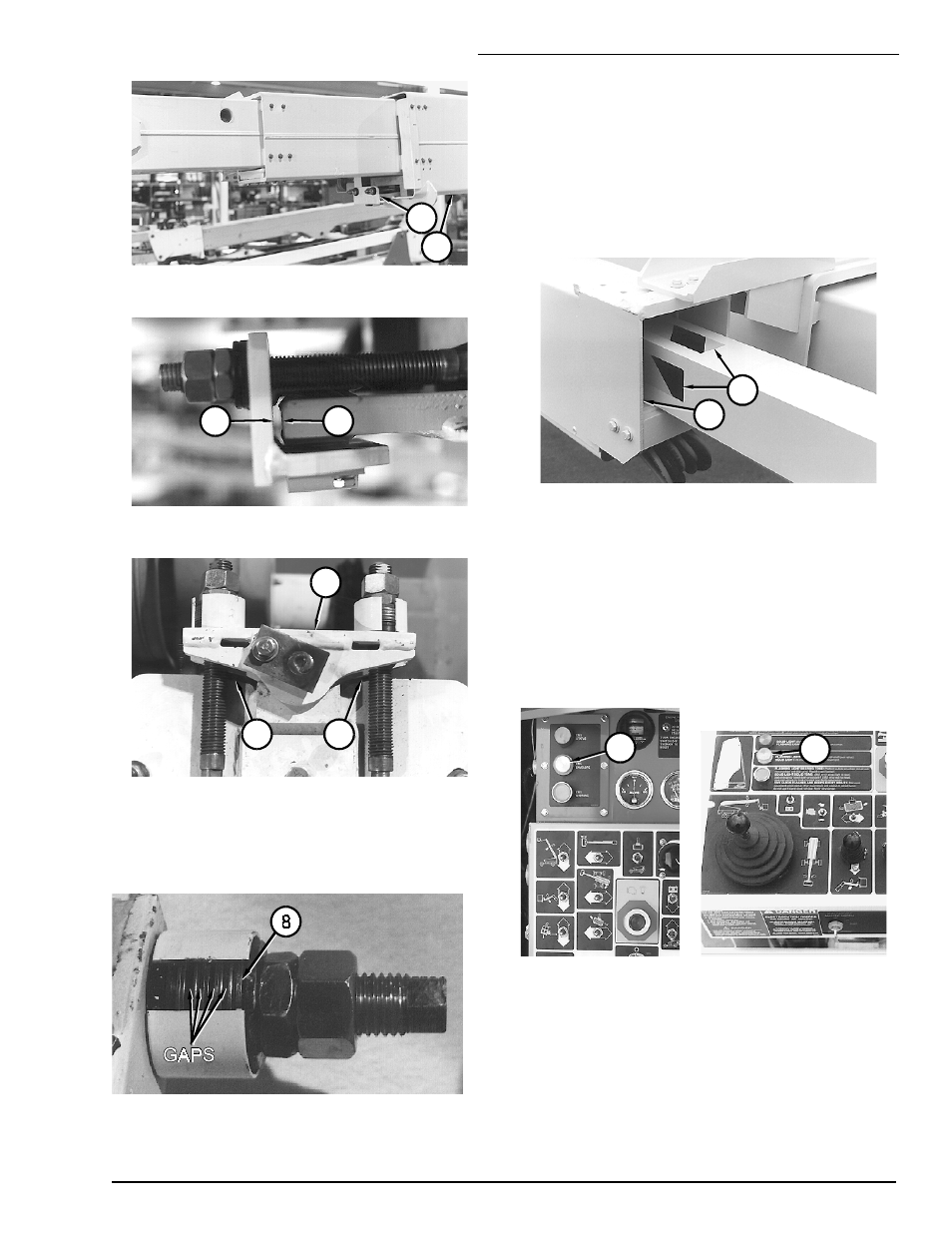

21. Whiffles and wire ropes

1

2

Visually inspect the whiffle (1) at the platform end

of the base boom (2).

3

4

The “inside” whiffle face (3) should not be

touching the whiffle support (4).

7

5

6

The top whiffle (5) should not be against either

whiffle stop (6) (7). If either whiffle (1) (5) is

canted so far it is against a stop, take the

TB100J out of service until a qualified service

technician adjusts the wire-ropes.

Check all spring washers (8) at both whiffles to

see that they are squashed completely together.

There should not be any gaps as shown here.

If any set of spring washers is found with gaps,

remove the TB100J from service immediately

and have a qualified service technician repair the

condition.

While you are inspecting the whiffles check the

condition of the wire ropes near the whiffles. The

wire ropes should not have any broken strands

or be distorted in any way.

22. Envelope management system

1

2

Extend and lock the rear axles.

Use the controls on the ground-control box to

raise the main boom slightly above horizontal.

Use the controls on the ground-control box to

extend the booms until they automatically stop.

The black & yellow tape (1) should be within 2

inches (5 cm) of being flush with the end of the

hose carrier cover (2) and the EMS ENVELOPE

lights (3) (4) should be on.

3

4

NOTE: The EMS ENVELOPE lights (3) (4)

should start to flash a few feet before boom

extension stops.

If the booms stop in the wrong place or the light

does not work correctly, take the TB100J out of

service immediately until a qualified service

technician makes repairs.