Snorkel TB100J User Manual

Page 63

10. DAILY INSPECTION & MAINTENANCE

10 - 4

P/N 0112478

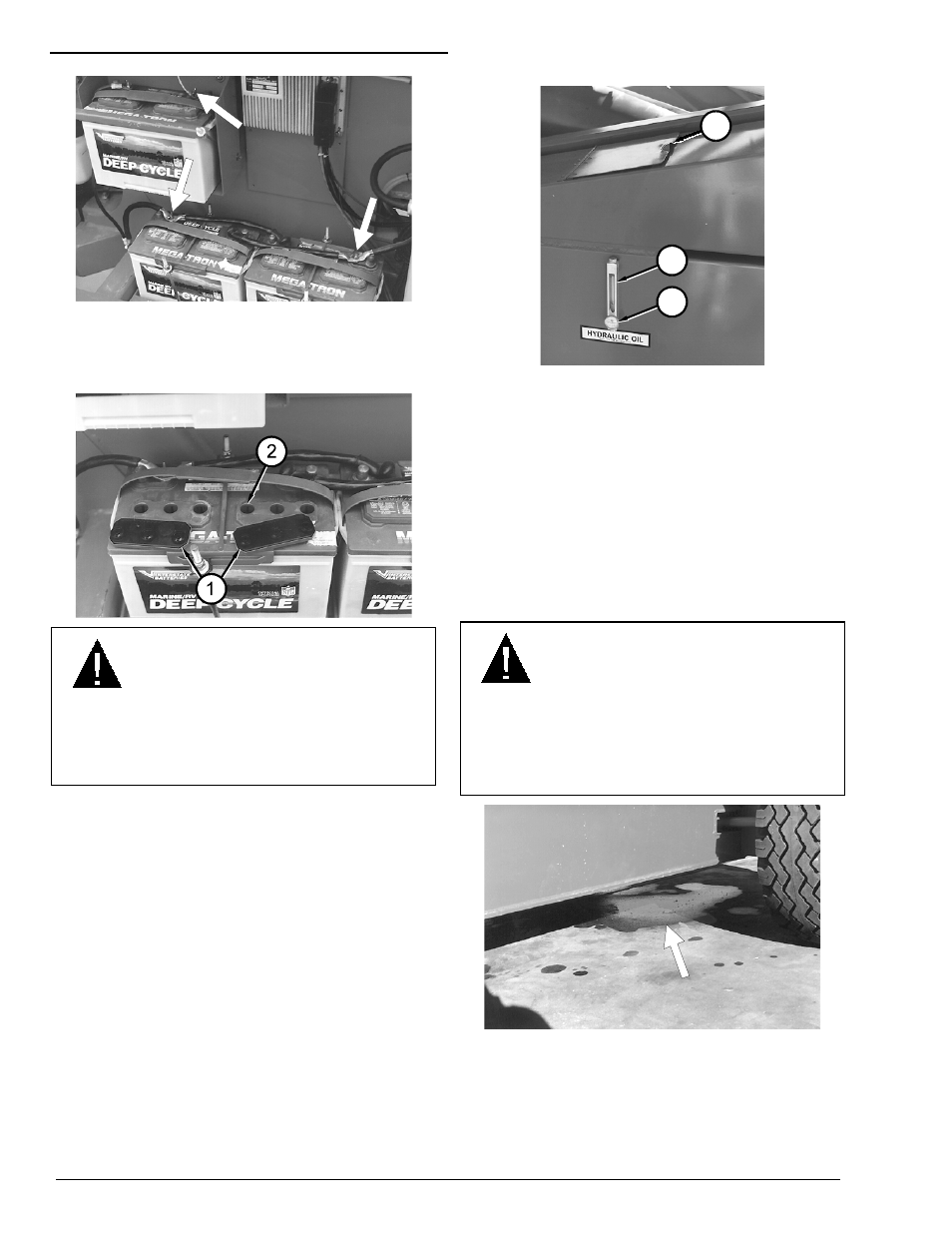

7. Battery terminals

Battery terminals should be clean and free of

corrosion.

8. Battery fluid level

D A N G ER

Batteries emit hydrogen and oxygen,

elements that can combine explosively. Do

not smoke or permit open flames or sparks

when checking batteries.

Remove the caps (1) from each battery and

visually check to see that the battery fluid is 1/4”

(6 mm) below the bottom of the filler neck inside

each hole (2).

9. Hydraulic oil

3

1

2

To check the hydraulic oil level:

Completely lower and completely retract the

booms.

The hydraulic oil temperature (1) should be

less than 200°F (93°C).

The hydraulic oil level should be between the

two marks on the sight-glass gauge (2).

If necessary, add hydraulic oil at the filler cap (3).

See the “SPECIFICATIONS” chapter for type

and grade of hydraulic oil.

10. Hydraulic oil leaks

D A N G ER

Leaking hydraulic oil can cause burns, fires,

falls (slipping), cuts, and puncture wounds (if

under high pressure). Have a qualified trained

maintenance person repair all hydraulic fluid

leaks before you operate the TB100J.

Hydraulic oil leaks are easily visible and can

show up anyplace. Visually inspect the entire

machine for hydraulic oil. Check the ground

under the machine for leaked oil.