5 axle replacement, Axle replacement – Lull 944E-42 Service Manual User Manual

Page 76

Axles, Drive Shafts, Wheels and Tires

5-4

944E-42

5.3.5

Axle Replacement

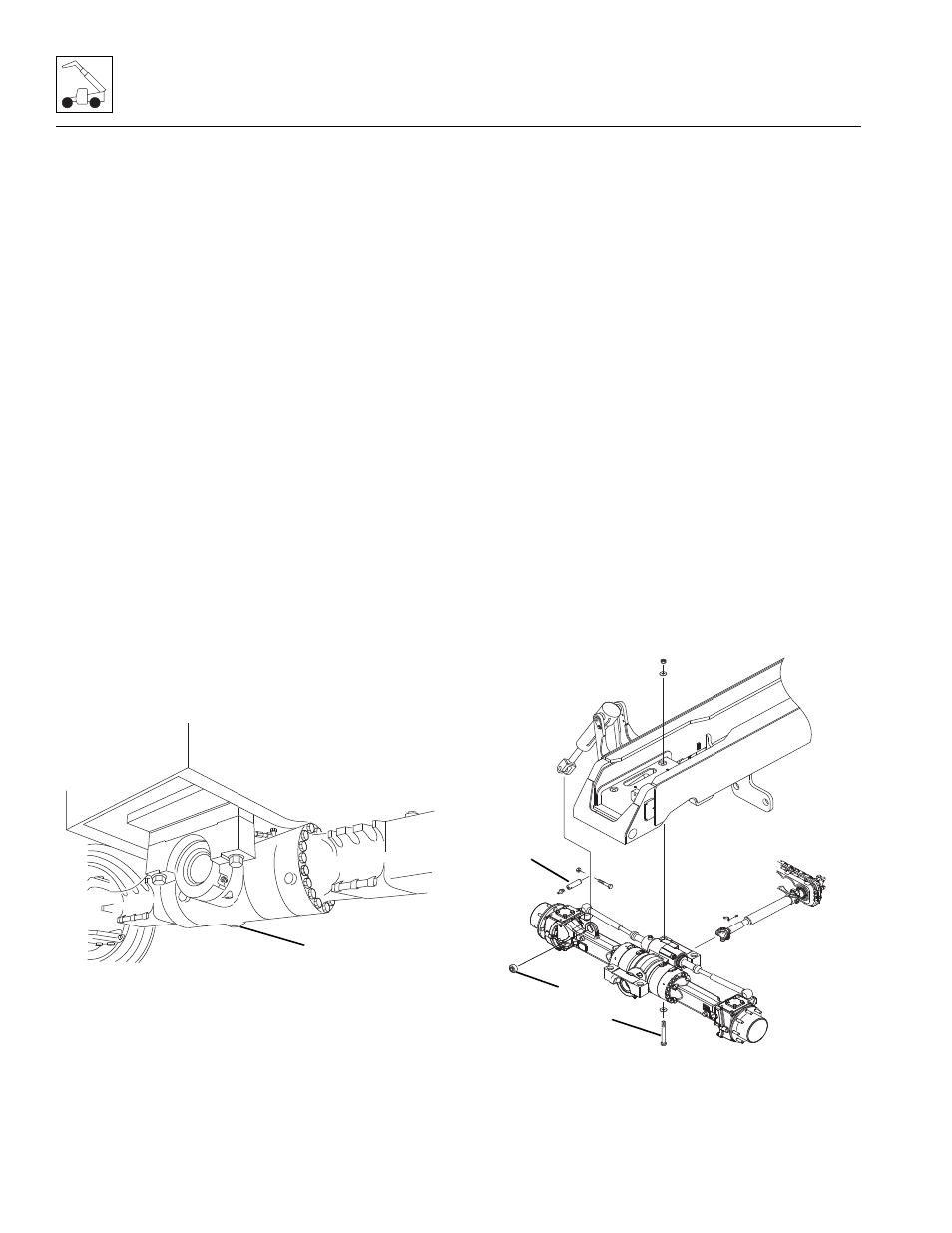

c. Axle Removal

The front and rear axle assemblies differ in that the front

axle assembly is equipped with a parking brake

mechanism and a limited-slip feature; the rear axle has

neither. The following steps outline a typical axle removal

procedure, suitable for either the front or the rear axle

assembly.

Cleanliness is extremely important. Before attempting to

remove the axle, thoroughly clean the machine. Avoid

spraying water or cleaning solution on the stabilizer

solenoids and other electrical components. If using a

steam cleaner, seal all openings before steam cleaning.

Note: Clear the work area of all debris, unnecessary

personnel, etc. Allow sufficient space to raise the

machine and to remove the axle.

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the travel select lever in the (N) NEUTRAL

position, engage the parking brake, straighten all

wheels and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Properly disconnect the batteries.

5. If the axle will be disassembled after removal, place

a suitable receptacle under the axle drain plug (1).

Remove the drain plug and allow the axle oil to drain

into the receptacle. Transfer the used axle oil into a

suitable covered container, and label the container

as “Used Oil.” Dispose of used oil at an approved

recycling facility.

6. Label, disconnect and cap the steering and brake

lines at the axle. Cap all fittings to prevent dirt &

debris from entering the hydraulic system. Wipe up

any spilled oil.

7. Block the front and rear of both tires on the axle that

is not being removed. Ensure that the machine will

remain in place during axle removal before

proceeding.

8. Raise the machine using a suitable jack or hoist.

Place suitable supports under both sides of the

frame and lower the machine onto the supports.

Ensure that the machine will remain in place during

axle removal.

9. Support the axle that is being removed with a suitable

jack, hoist or overhead crane and sling. DO NOT

raise the axle or the machine.

10. Remove both wheel and tire assemblies from the

axle that is being removed. (Refer to Section 5.5.1,

“Removing Wheel and Tire Assembly from

Machine.”)

Note: The wheel and tire assemblies must be re-installed

later with the directional tread pattern “arrows” facing in

the direction of forward travel.

11. Remove the drive shaft assembly. Refer to Section

12. Remove the capscrew and locknut securing the

lower position cylinder-mount pin (2) to the cylinder.

Tap the cylinder mount pin out, and move the

cylinder to prevent it from interfering with axle

removal.

MU0581

1

MU6790

2

3

4