Lull 944E-42 Service Manual User Manual

Page 46

Boom

3-16

944E-42

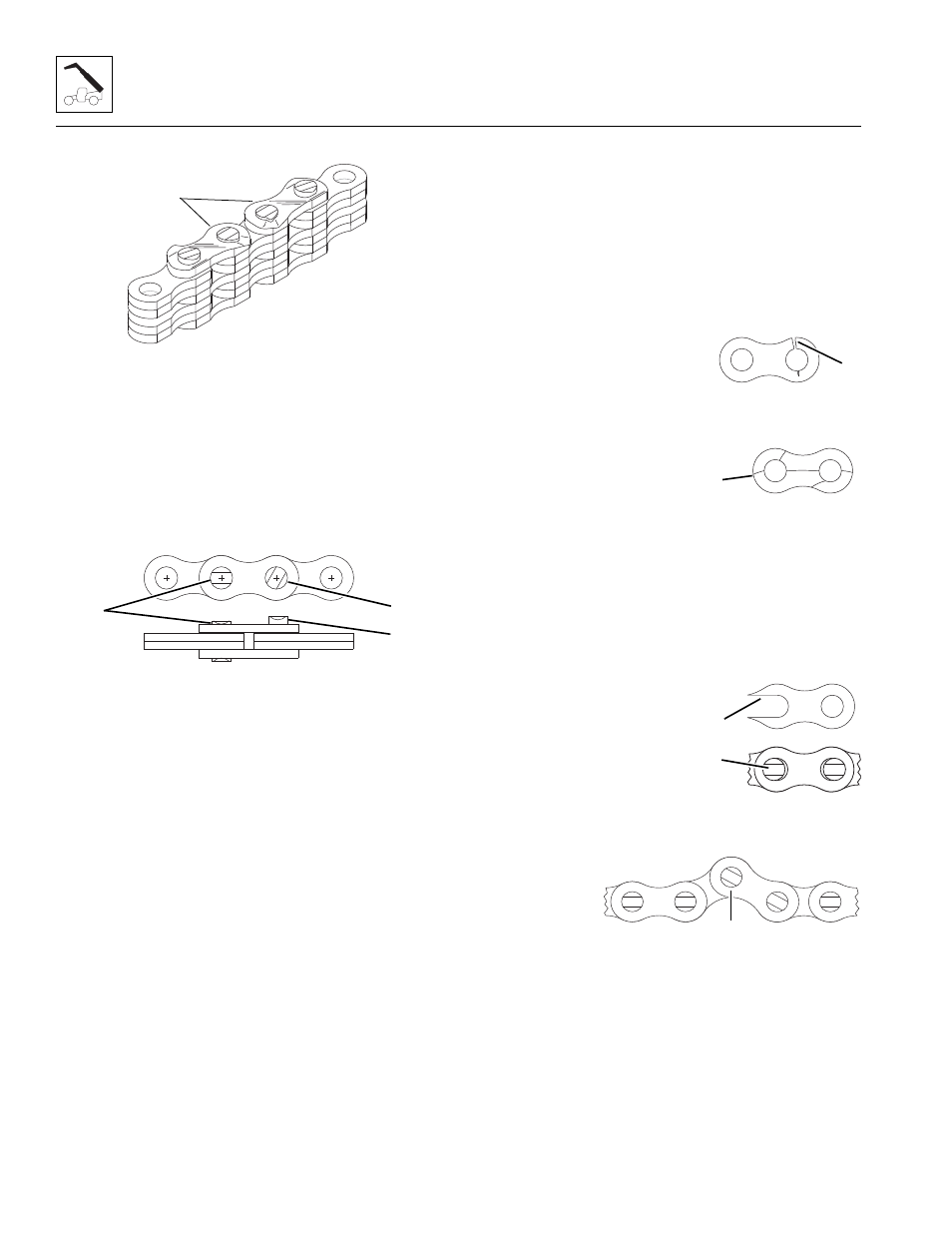

Distorted or Battered Link Plates

Distorted or battered link plates (5) on a leaf chain can

cause tight joints and prevent flexing.

Turning or Protruding Pins

Highly loaded chain, operating with inadequate

lubrication can generate abnormal frictional forces

between pin and link plates. When chain is allowed

to operate in this condition, a pin or series of pins,

can begin to twist out of a chain, resulting in failure.

Examine the pin head rivets to determine if the

“VEE” flats are still in correct alignment (6). Chain

with rotated/displaced heads (7) or abnormal pin

protrusion (8) should be replaced immediately.

DO NOT attempt to repair the chain by welding or

driving the pin(s) back into the chain. Once the press

fit integrity between outside plates and pins has

been altered, it cannot be restored.

Any wear pattern on the pin heads or the sides of the

link plates indicates misalignment in the system.

This condition damages the chain as well as

increases frictional loading and should be corrected.

Cracked Plates

Inspect the chains very carefully, front and back as

well as side to side, for any evidence of cracked

plates. If any one crack is discovered, the chain

should be replaced in its entirety.

It is important, however to determine the cause of

the crack before installing a new chain so the

condition does not repeat itself.

The types of cracks are:

• Fatigue Cracking -

Fatigue cracks (9) are a

result of repeated

cyclic loading beyond

the chain’s endurance

limit.

• Stress Corrosion

Cracking - The

outside link plates

are particularly

susceptible to stress

corrosion cracking (10).

• Corrosion Fatigue Cracking - Corrosion

fatigue cracks are very similar to fatigue

cracks in appearance. Corrosion fatigue is the

combined action of an aggressive

environment and cyclic stress.

Other Modes of Failure

• Ultimate Strength Failure -

These types of failures are

caused by overloads far in

excess of the design load.

Either fractured plates (1) or

enlarged holes (2) can

occur. If either of these

failures occurs, the chain

should be replaced immediately.

• Tight Joints

- All joints in

the chain

should flex

freely. Tight

joints (3)

resist flexing.

If the problem is caused by dirt or foreign substance

packed in the joints, clean and lubricate thoroughly

before re-installing the chain.

If the problem is caused by corrosion and rust or

bent pins, replace the chain.

8

MZ1466

5

MZ1465

6

7

8

MZ1467

9

MZ1468

10

MZ1469

MZ1470

1

2

MZ1471

3