4 hydraulic circuits, 1 hydraulic pressures, Hydraulic circuits – Lull 944E-42 Service Manual User Manual

Page 121: Section 8.4, “hydraulic, Circuits, Hydraulic pressures, Caution

8-5

944E-42

Hydraulic System

7. Check the pressure gauge reading. It should read as

specified in the Pressure Readings column of the

charts found in Section 8.4.1, “Hydraulic Pressures.”

If the reading is not as specified, turn the engine

OFF and check other components in the system.

Verify that all related hydraulic components and

electrical switches, sensors, solenoids, etc. are

operating correctly.

8. Adjust the relief valve by turning the adjustment

screw Turning clockwise will increase the pressure;

turning the screw counterclockwise will decrease the

pressure.

9. Start the engine and check the pressure again. Turn

the engine OFF. If there is pressure reading in the

gauge, bleed it off then disconnect or remove the

pressure gauge from the machine.

8.4

HYDRAULIC CIRCUITS

This section covers the hydraulic circuits and includes

listings for all hydraulic function pressures, where and

how to check those pressures and a hydraulic schematic.

Electrical and hydraulic functions are often related. Verify

that the electrical components of the circuit are

functioning properly whenever troubleshooting the

hydraulic circuit.

Always check the following before beginning to

troubleshoot a circuit that is not functioning correctly.

1. Check the hydraulic oil level in the reservoir. Oil level

should be to the middle of the sight glass with all

cylinders retracted.

2. Check hoses, tubes, fittings and other hydraulic

components for leaks, bends, kinks, interference, etc.

3. Check for air in the hydraulic system. Erratic machine

performance and/or spongy cylinder operation are

signs of air in the hydraulic system.

If air in the hydraulic system is suspected, you will

hear air leakage when hydraulic fittings are loosened

and see air bubbles in the hydraulic fluid.

Loose fittings, faulty o-rings or seals, trapped oil,

leaks, system opened for service, etc., can cause air

in the system. Determine what is causing air to enter

the system and correct it. Bleed air from the system.

8.4.1

Hydraulic Pressures

a. Checking Pressure

1. Start the machine and warm the hydraulic system to

operating temperature.

2. Shut off the machine and install a gauge of suitable

pressure rating according to the following chart to

the appropriate test port.

3. Start the machine, run the engine and follow the

procedures in Section 8.4.1, c. “Hydraulic Testing -

Dual Joysticks.”

b. Adjusting Hydraulic Pressure

1. Shut the machine off. Remove the cap on the relief

(if necessary).

2. Start the machine and loosen the jam nut on the

relief. Turn the relief clockwise to increase pressure

or counter-clockwise to decrease pressure. Set to

the correct pressure.

3. Tighten the jam nut and recheck the pressure at full

throttle. If the reading is within specification, shut the

machine off, install the safety cap and remove the

gauge from the test port.

4. If the proper pressure cannot be set, use the

accompanying hydraulic schematic and/or the

electrical schematic to help troubleshoot and correct

the problem.

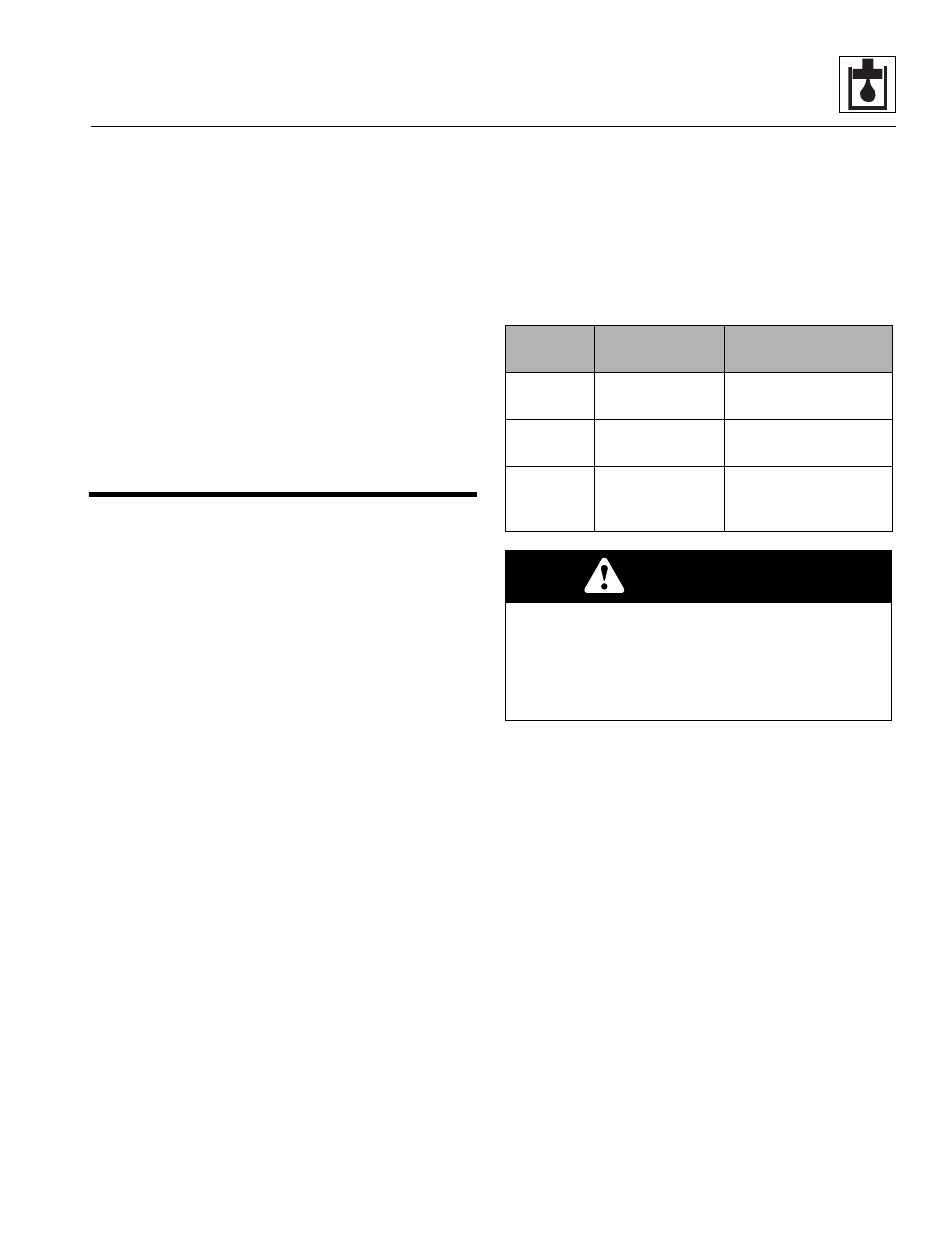

Test

Location

Gauge

Fittings

2, 3, 4, 5

4000 psi gauge

(280 bar gauge)

Unit equipped with

fittings from factory.

6, 7, 8, 10

1000 psi gauge

(70 bar gauge)

Unit equipped with

fittings from factory.

9

4000 psi gauge

(280 bar gauge)

Requires a male or

female quick

disconnect coupler.

CAUTION

GAUGE DAMAGE may occur. Malfunctioning

hydraulic system circuits may have excessive

pressure and can cause hydraulic pressure spikes.

Test circuit with the highest reading pressure gauge

first. If this gauge cannot record an accurate pressure

reading, use the next lower pressure gauge.