6 front upstop wear pad check, 7 front upstop wear pad gap check, 8 front upstop wear pad shimming – Lull 944E-42 Service Manual User Manual

Page 251: Front upstop wear pad check -11, Front upstop wear pad gap check -11, Front upstop wear pad shimming -11, D section 11.3.6, “front upstop wear pad check.”), Section 11.3.6, Front upstop wear pad check.”)

11-11

944E-42

Transfer Carriage

11.3.6

Front Upstop Wear Pad Check

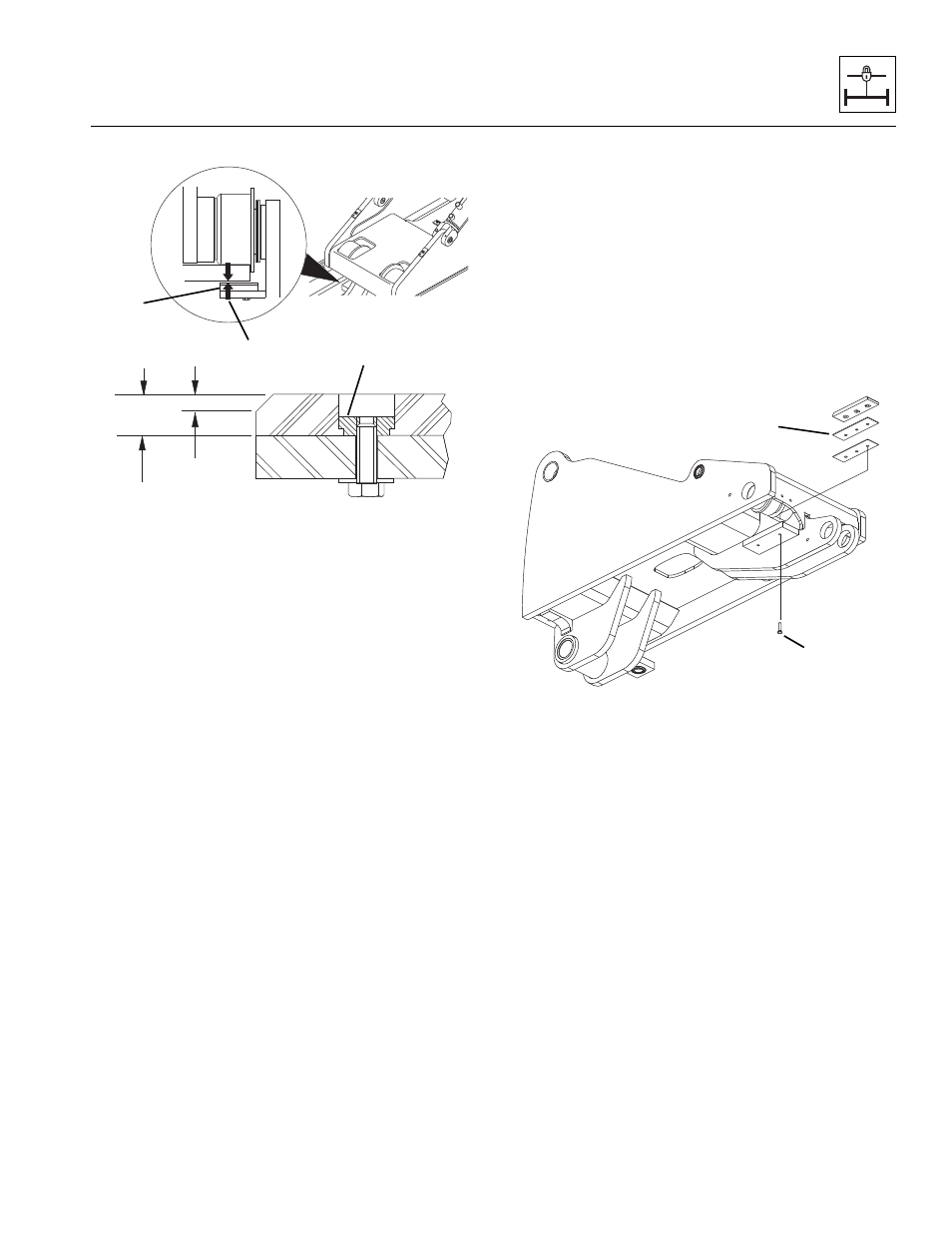

The front upstop wear pads (5) are located under the

frame rails at the front of the transfer carriage.

Each wear pad is manufactured with a convenient wear

pad indicator. This is the angled cut at each end of all

wear pads.

The total thickness (6) of a new wear pad is 0.625 in

(16 mm). The angled cut will provide a total wear

thickness (7) of 0.25 in (6 mm). This will leave

approximately 0.375 in (10 mm) of total unused base

material.

The pads must never be worn past the angled cut

indicator because the metal pad insert (8), that holds the

pads in place, will begin to wear into the rail surfaces. If

the pad wears past this point, the metal insert in the pad

will begin to gouge the metal surfaces.

11.3.7

Front Upstop Wear Pad Gap Check

Note: The attachment should remain attached to the

quick attach for these checks.

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom and transfer

carriage, level the boom, place the transmission

control lever in (N) NEUTRAL, engage the park

brake and shut the engine OFF.

2. Check the gap (9) between the top of the wear pad

and the bottom of the rail. The maximum gap should

be 0.12" (3 mm).

11.3.8

Front Upstop Wear Pad Shimming

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, level the boom,

place the transmission control lever in

(N) NEUTRAL, engage the park brake and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the engine cover. Allow the system fluids to

cool.

4. Properly disconnect the batteries.

5. Remove capscrews (10), shims, and front wear

pads (11). Label their position for later replacement.

Note: New shims have a 0.06 inch (1,5 mm) thickness.

6. Add new shims to the left and/or right side shim

groups as required to achieve proper gap

maximums. Spread shims evenly between the left

and right shim groups.

7. Coat the capscrews with Loctite

®

242 (blue). Replace

capscrews, shims, and front wear pads (11) in their

previously labeled positions. Torque the capscrews

to, 21 - 38 lb-ft (29 - 52 Nm).

8. Properly connect the batteries.

9. Close and secure the engine compartment cover.

OU1001

OU0991

5

6

7

8

9

MU1801

10

11