Leaning lean of peak – J.P. Instruments EDM 700/800/711 Pilots Guide User Manual

Page 20

Page 16

Engine Data Management

To use the “lean of peak” method, tap LF and then immediately hold

both STEP and LF until you see

LEAN L. Once you begin leaning

(flashing dot) you cannot change leaning methods. You may toggle back

to

LEAN R by holding both buttons again.

Leaning Lean of Peak

-5 7.3

73

HP

1

2

3

4

5

6

T

_

STEP

LF

EDM

800

JPI

_

EGT

%

Limit

_

300

400

500

CHT

TSO

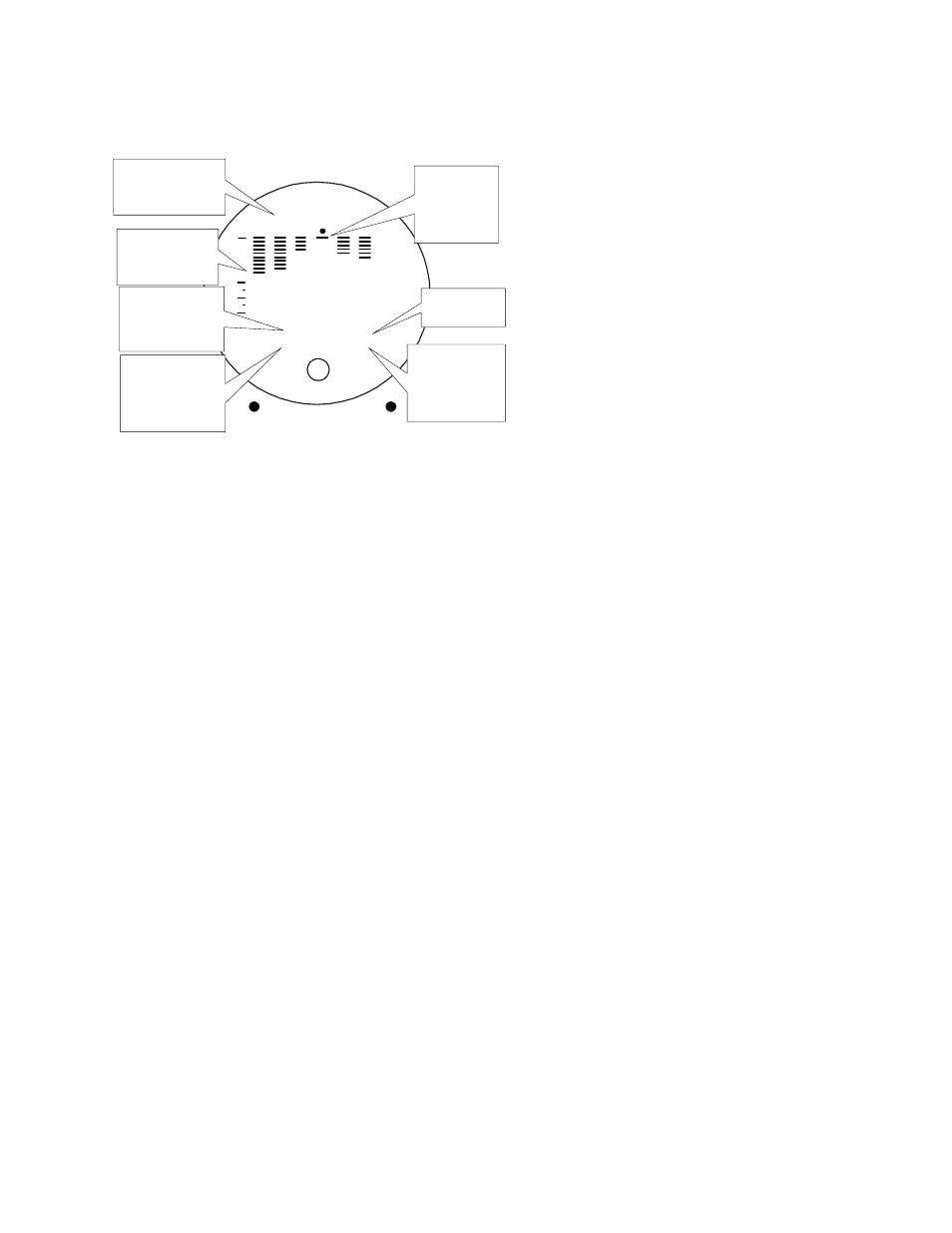

Cylinder number

flashes when the

cylinder peaks

Temperature

below peak of

last cylinder to

peak

Shortest

column is

the last

cylinder to

peak

Current fuel

flow rate

First cylinder to

peak has

largest column

Hold LF to see

peak

temperature of

last cylinder to

peak (e.g.

I340)

Hold LF to see

GAMI spread

(delta fuel flow)

In the “lean of peak” method the columns will invert with the first to

peak progressing down from the top of the display. The inverted column

scale is 5° per segment below peak. As you continue to lean past peak

the dot of the each successive cylinder will flash as it peaks. The peaks

will be shown as an inverted bar graph; when the last cylinder peaks

its column will flash. The analog display is an inverted bar graph

showing where each cylinder peaked. When the LF button is held the

display will show the delta fuel flow between the first and last to peak

(GAMI Spread), as well as the richest peak EGT.

If you tap STEP, scanning will resume. Or instead, if you Tap LF you

will return to the inverted bar graph, which can be used for fine tuning.

To begin the LeanFind procedure anew, tap LF a second time.

Turbocharged Engines

The leaning process for turbocharged engines is by reference to the first

cylinder or TIT to reach peak. However, the TIT factory red line may

limit the leaning process. TIT red line is generally 1650°F, and up to

1750°F in some installations. In the LeanFind mode the T column—

TIT—is included in the procedure. If during leaning the TIT exceeds red

line by less than 100° for less than one minute, the LeanFind procedure

will continue to operate, allowing you to complete the leaning process.

Otherwise the digital display will show, for example,

I650 TIT and TIT will