Pipe deck flashing installation, Selection chart material information – Mueller Pre-Fab User Manual

Page 100

877-2-MUELLER

G-8

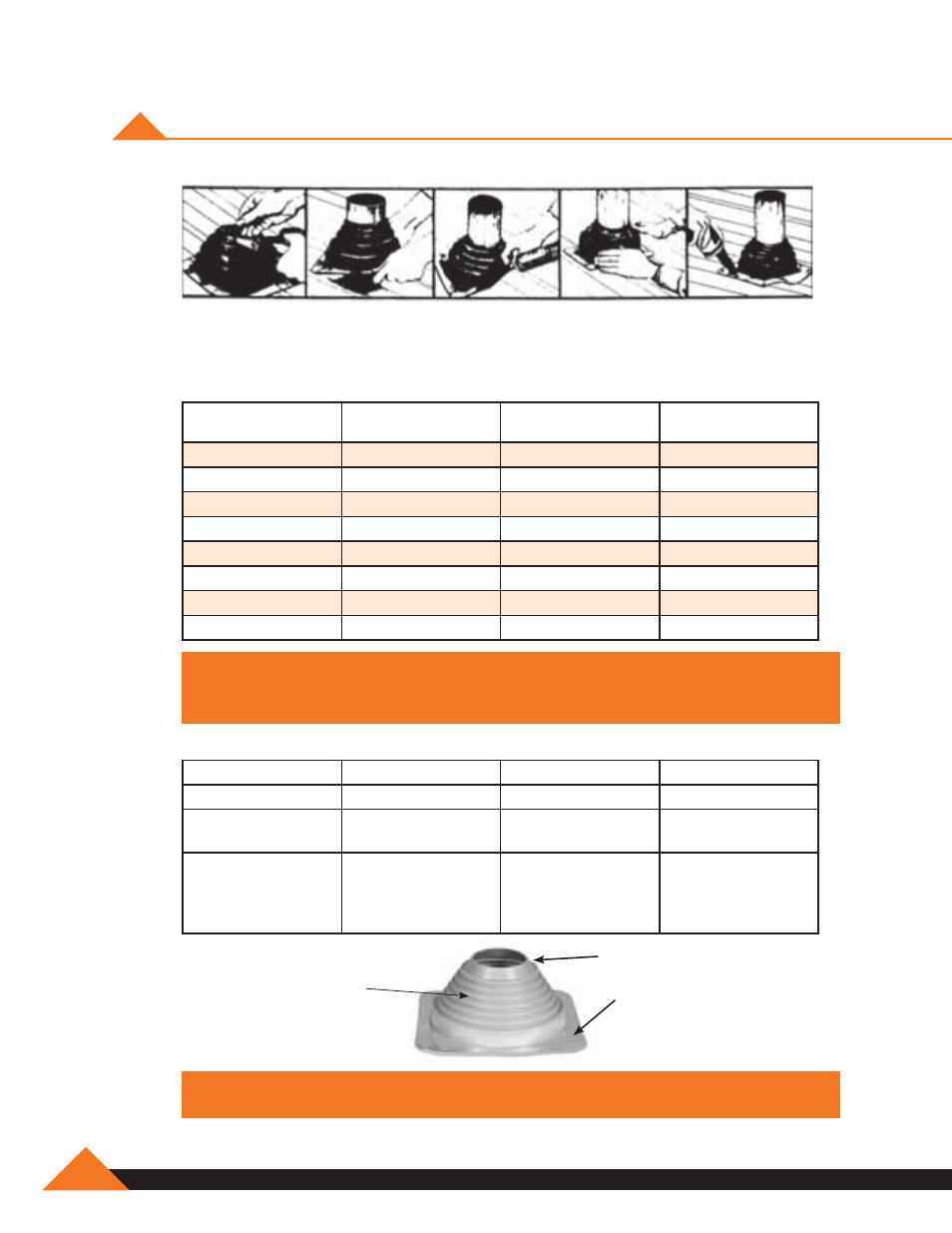

PIPe DecK flasHInG InsTallaTIon

selection chart

Material Information

Pipe opening is quickly and easily

customized on the job .

Tough EPDM, silicone or Neoprene

rubber resists weathering,

ultraviolet light and cracking .

1. TRIM

Cut opening to 20%

smaller than pipe

diameter .

2. slIDe

Slip pipe flash over pipe .

3. seal

Apply urethane/silicone

sealant between pipe

flash and roofing .

4. foRM

Bend aluminum base to

fit irregularities . Use large

slot screwdriver to press

into tight angles .

5. fasTen

Complete the seal using

common weather-

resistant fasteners .

Aluminum base bends to form a

perfect seal on all roof pitches,

contours or surface irregularties .

Square flange design adapts to

any roofing material .

note: numbers 1 & 3 are closed top. When using pipe flash on very steep pitched roof

or surface with deep corrugation, use next largest size for increased flange flexibility.

note: specify neoprene when Pipe flash is to be exposed to petrochemicals.

Master Flash

Number

Pipe Size

Base Dimension

Opening Diameter

1

1

/

4

" - 2"

4

1

/

2

"

Closed

2

1

1

/

4

" – 3"

6"

7

/

8

"

3

1

/

4

" – 4"

8"

Closed

4

3" – 6"

10"

2

1

/

2

"

5

4" – 7"

11"

3

1

/

2

"

6

5" – 9"

12"

4"

7

6" – 11"

14"

5"

8

7" – 13"

17"

6"

Material

Neoprene

EPDM

Silicone

Guarantee

10 years

20 years

20 years

Temperature Range

-45 degree to

+200 degree

-65 degree to

+250 degree

-100 degree to

+450 degree

Applicable

ASTM D2000,

M2 BC 510 A14,

B14, C12, F17,

Z1, Z2, Z3

ASTM D2000,

M3 BA 510 A14,

B13, C12, F17,

Z1, Z2, Z3

ASTM D2000,

M4 GE 505 A19,

B37, C12, F19,

Z1, Z2, Z3