4 chain lubrication, 11 forks, Forks – SkyTrak 8042 Service Manual User Manual

Page 91: Chain lubrication

3-53

6036, 6042, 8042, 10042, 10054

Boom

3.10.4

Chain Lubrication

After inspection and before being returned to service,

chains must be lubricated with Mystik Tetrimoly Grease.

The lubricant must penetrate the chain joint to prevent

wear. Applying lubricant to the external surfaces will

prevent rust, but the chains should be articulated to

make sure the lubricant penetrates to the working

surfaces between the pins and links.

To prepare the chain for lubrication, the chain plates

should be brushed with a stiff brush or wire brush to

clear the space between the plates so that lubricant can

penetrate to the working surfaces.

Lubricant may be applied with a narrow paint brush or

directly poured on, but the chain should be well flooded

with lubricant and the boom should be extended and

retracted to be sure that the lubricant penetrates to the

working surfaces. All surplus lubricant should be wiped

away from the external surfaces. DO NOT use a solvent

for this wiping operation.

Regular application of lubricant is necessary to make

sure that all working surfaces are adequately lubricated.

In extremely dusty conditions, it may be necessary to

lubricate the chains more often. Refer to Section 2.5,

“Service and Maintenance Schedules,” and Section 2.6,

“Lubrication Schedules,” for detailed information.

Lubrication of chains on vehicles working consistently in

extreme hot or cold conditions requires special

consideration. Contact the local distributor for guidance.

3.11

FORKS

Forks should be cleaned and inspected prior to being

attached to carriage. If the following criteria is not met,

forks must be removed from service immediately.

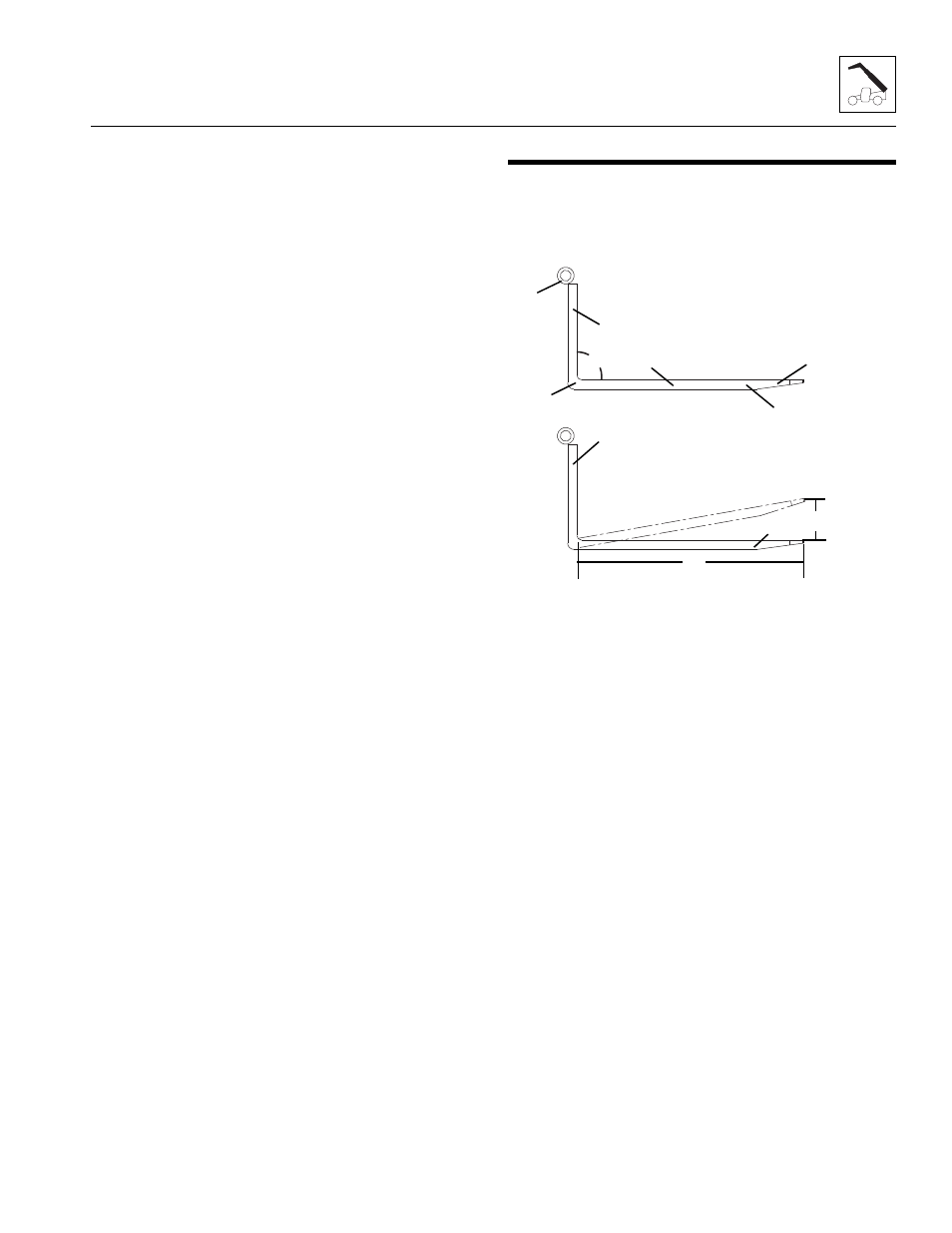

Daily Inspection

1. Inspect forks (4) for cracks, paying special attention

to heel (5) and mounting tubes (6).

2. Inspect forks for broken or bent tips (7) and twisted

blades (8) and shanks (9).

Yearly Inspection

1. Straightness of the upper face of blade (8) and the

front face of shank (9) should not exceed 0.5 percent

of the length of blade or height of shank.

2. Angle (10) between upper face of blade and front

face of shank should not exceed 93 degrees.

3. Thickness of blade (13) and shank (14) should not

be reduced to 90 percent of original thickness.

4. Ensure fork length (12) is adequate for intended

loads.

5. Fork markings should be legible, re-stamp if

required.

6. Compare fork tips (11) when mounted on a carriage.

Maximum difference in height of fork tips is 3 percent

of the length of the blade (13).

MH6460

6

5

9

10

8

4

7

14

13

12

11