8 outrigger valve (10042 & 10054 only) – SkyTrak 8042 Service Manual User Manual

Page 174

Hydraulic System

8-30

6036, 6042, 8042, 10042, 10054

8.7.8

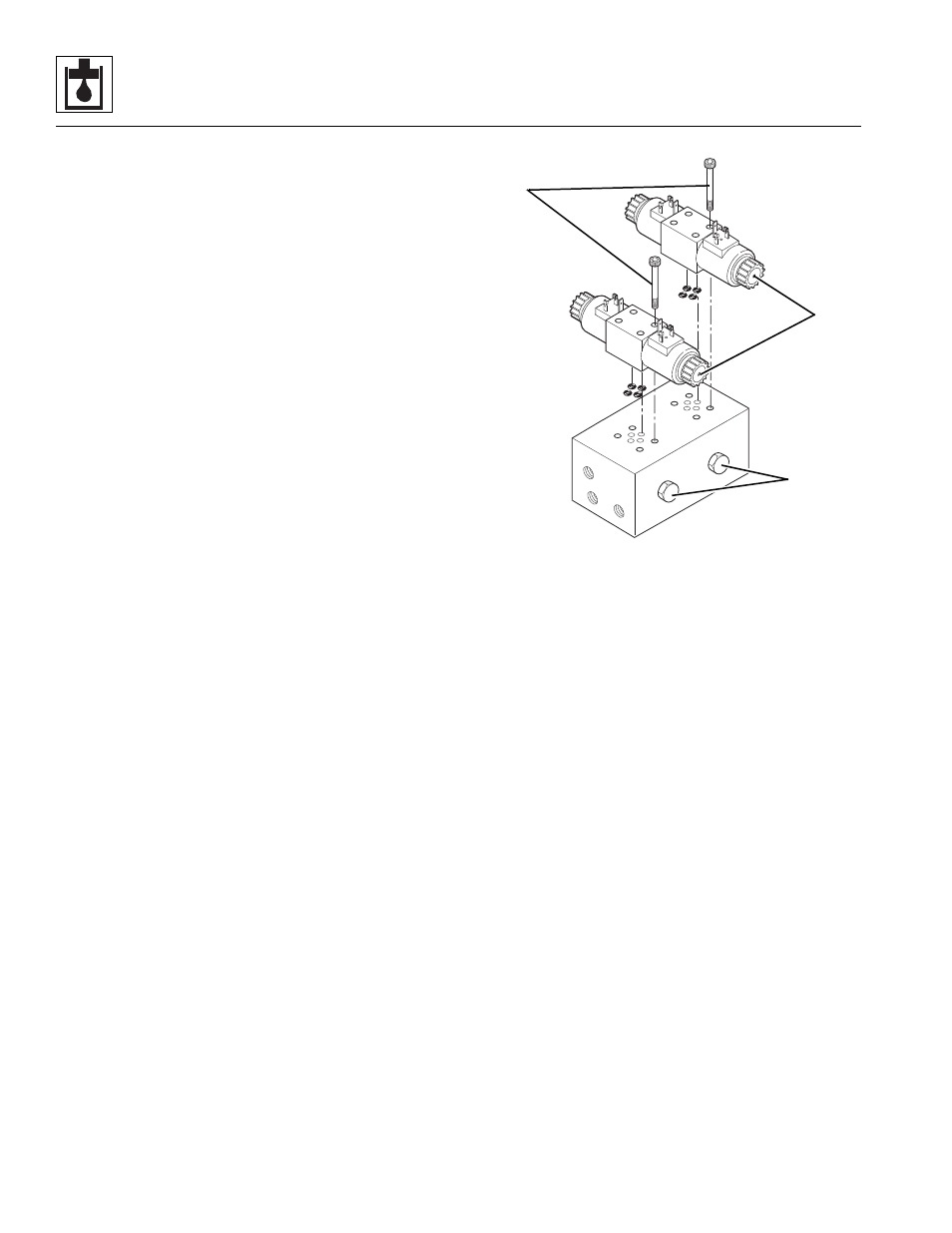

Outrigger Valve (10042 & 10054 only)

The outrigger valve allows the left and right outriggers to

be raised or lowered depending on the position of the

outrigger switches located on the side console in the cab.

Verify the correct operation of the outrigger valve

solenoids before considering replacement of the valve.

a. Outrigger Valve Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, raise the boom, place

the transmission control lever in (N) NEUTRAL,

engage the park brake and shut the engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and the steering wheel, stating that the

machine should not be operated.

3. Temporarily block up or support the raised boom.

4. Open the rear door. Allow the system fluids to cool.

5. Properly disconnect the battery.

6. Remove the transmission covers.

7. Label, disconnect and cap the hydraulic hoses and

the electrical plugs connected to the outrigger valve.

8. Remove the two flange nuts and two carriage bolts

securing the outrigger valve to the frame. Remove

the outrigger valve from the machine.

9. Wipe up any hydraulic fluid spillage in, on, near and

around the machine, work area and tools.

b. Outrigger Valve Disassembly, Cleaning,

Inspection and Assembly

1. Place the outrigger valve assembly on a suitable

work surface.

2. Remove the solenoid valve assemblies (2) from the

outrigger valve by removing the four capscrews (3).

Discard the four o-rings.

3. Remove the shuttle cartridges (4) from the outrigger

valve.

4. Clean all components with a suitable cleaner before

inspection.

5. Inspect the solenoid cartridges for proper operation.

Check by shifting the spool to ensure that it is

functioning properly. Check that the spring is intact.

Inspect the cartridge interior for contamination.

6. Inspect internal passageways of the outrigger valve

for wear, damage, etc. If inner surfaces of the valve

DO NOT display an ultra-smooth, polished finish, or

components are damaged in any way, replace the

valve or appropriate part. Often, dirty hydraulic fluid

causes failure of internal seals and damage to the

polished surfaces within the secondary function

manifold.

Note: ALWAYS replace seals, o-rings, gaskets, etc.,

with new parts to help ensure proper sealing and

operation. Lubricate seals and o-rings with clean

hydraulic oil.

7. Install the shuttle cartridges into the outrigger valve.

Torque to 35 lb-ft (48 Nm).

8. Attach the solenoid assemblies to the outrigger

valve using four new, oiled o-rings and the

previously used capscrews.

P

S

T

MH3881

2

3

4