9 engine replacement, 1 engine removal, 2 engine installation – SkyTrak 8042 Service Manual User Manual

Page 141: Engine replacement, Engine removal, Engine installation

7-9

6036, 6042, 8042, 10042, 10054

Engine - Cummins QSB3.3T/QSB4.5T

7.9

ENGINE REPLACEMENT

7.9.1

Engine Removal

Note: The radiator and oil cooler must be removed from

the machine before engine removal. Refer to

7.4, “Engine Cooling System.” Several additional

components must be removed before engine removal.

They will be addressed in the following procedures.

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the travel select lever in the (N) NEUTRAL

position, engage the parking brake, and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the rear door. Allow the system fluids to cool.

4. Properly disconnect the battery.

5. Remove the rear door and engine side covers.

6. Drain and remove the radiator assembly. Refer to

Section 7.4.2, “Radiator/Oil Cooler and

Replacement.”

7. Remove the radiator overflow tube, overflow tank

and hose support.

8. Label, disconnect and cap the heater hoses

attached to the engine (if equipped).

Note: The engine harness is routed and attached to the

engine using hold-down clamps and plastic wire ties at

various places on the engine. Before removing engine,

ensure that the harness has been completely separated

(disconnected) from the engine. Move the harness clear

of the engine, and with the help of an observer, ensure

that the engine clears the harness during removal.

9. Label and disconnect all electrical wire connections

on the engine.

10. Label, disconnect and cap the fuel inlet line at the

fuel lift pump.

11. Label, disconnect and cap the fuel return line from

the injector pump.

12. Remove the engine-to-transmission drive shaft.

Refer to Section 5.6.3, “Drive Shaft Removal.”

Note: Before the engine can be removed from the

machine, the air conditioning hoses need to be removed

from the air conditioning compressor. This procedure

must be completed by an authorized air conditioning

service technician. This service technician will also need

to be available when the new engine is installed to re-

install the air conditioning hoses and to the air

conditioning compressor.

13. Loosen the clamps on the sleeve reducer at the

engine and on the air suction pipe.

14. Remove the air cleaner assembly. Refer to Section

7.8.1, “Air Cleaner Assembly Removal.”

15. Remove the exhaust pipe from the exhaust

manifold. Refer to Section 7.7.1, “Exhaust System

Removal.”

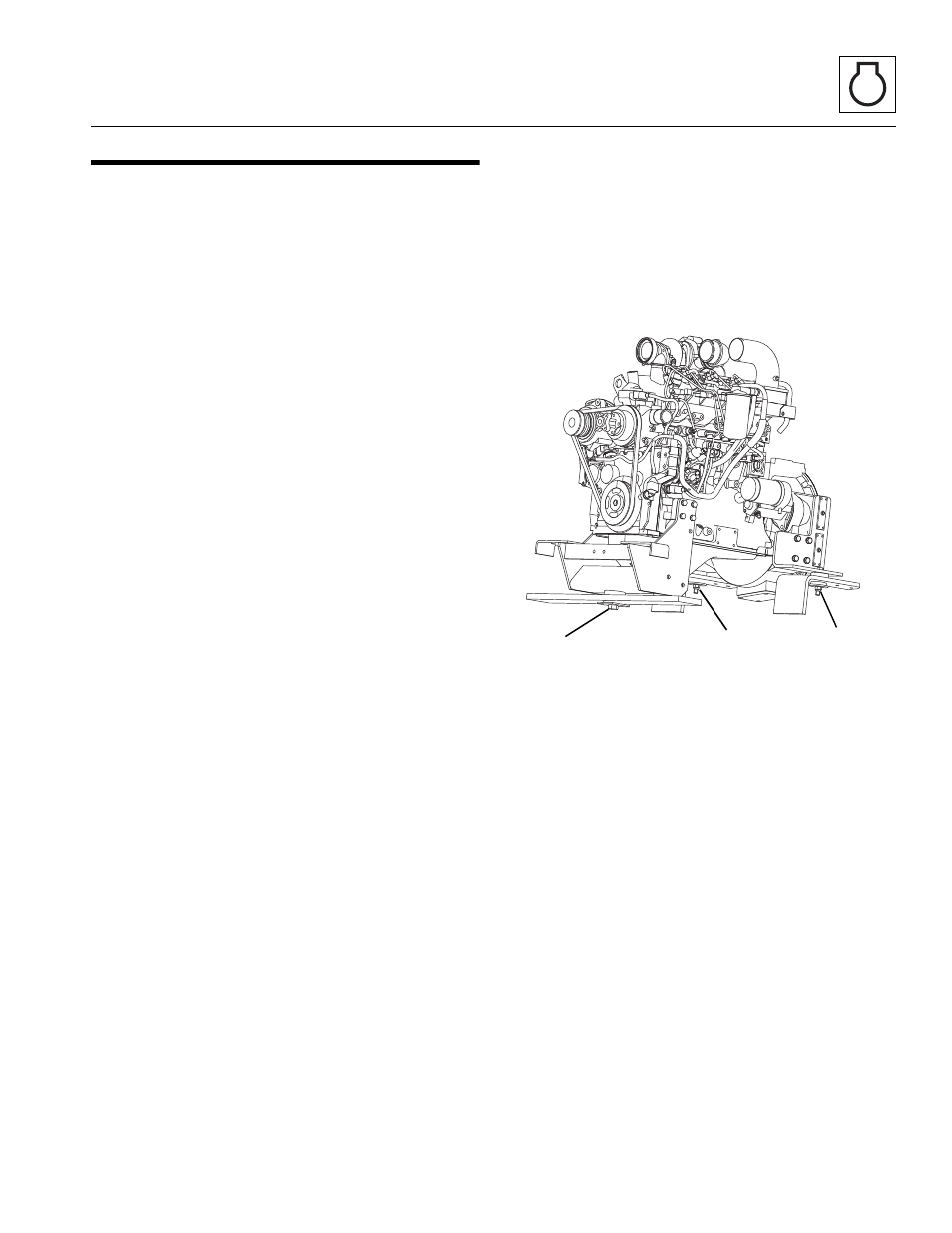

16. At the front right engine mount (5), remove the

hardware securing the mount to the frame. Repeat

procedure for left engine mount (6).

17. Remove the hardware securing the rear engine

mount (7).

18. Remove the exhaust pipe bracket.

19. Position a fork truck behind the machine, and drive

forward, placing the forks underneath the rear

engine mount and front engine mount brackets.

Slightly lift the engine, and slowly back engine out of

the machine. Have an assistant ensure that the

engine clears all frame components during removal.

20. Place engine on a flat, level surface.

21. If replacing engine, attach a lifting chain to the front

and rear engine lift brackets, and lift engine clear of

the ground.

22. Remove the three engine mounting brackets.

7.9.2

Engine Installation

Note: The engine harness is routed and attached at

various places on the engine using hold-down clamps

and plastic wire ties. Before installing engine and with

MAQ0320

6

7

5