2 engine serial number, 3 specifications and maintenance information, 4 engine cooling system – SkyTrak 8042 Service Manual User Manual

Page 136: 1 radiator pressure cap, 2 radiator/oil cooler and replacement, Engine serial number, Specifications and maintenance information, Engine cooling system, Radiator pressure cap, Radiator/oil cooler and replacement

Engine - Cummins QSB3.3T/QSB4.5T

7-4

6036, 6042, 8042, 10042, 10054

7.2

ENGINE SERIAL NUMBER

The Cummins QSB3.3T/QSB4.5T serial number is

stamped on a plate which is typically located on the

engine rocker cover, but may be located on the side of the

gear housing. Information contained in the serial number

is required in correspondence with the engine

manufacturer.

7.3

SPECIFICATIONS AND

MAINTENANCE INFORMATION

For engine, coolant and oil specifications, and

maintenance information, refer to Section 2, “General

Information and Specifications.”

Note: Detailed Cummins engine service instructions

(covering disassembly, inspection, internal repair,

assembly, adjustment and troubleshooting information)

are provided in the appropriate Cummins engine service

manual.

7.4

ENGINE COOLING SYSTEM

7.4.1

Radiator Pressure Cap

For a 210° F (99° C) system, use a 13 psi (90 kPa)

radiator cap. An incorrect or malfunctioning cap can

result in the loss of coolant and a hot-running engine.

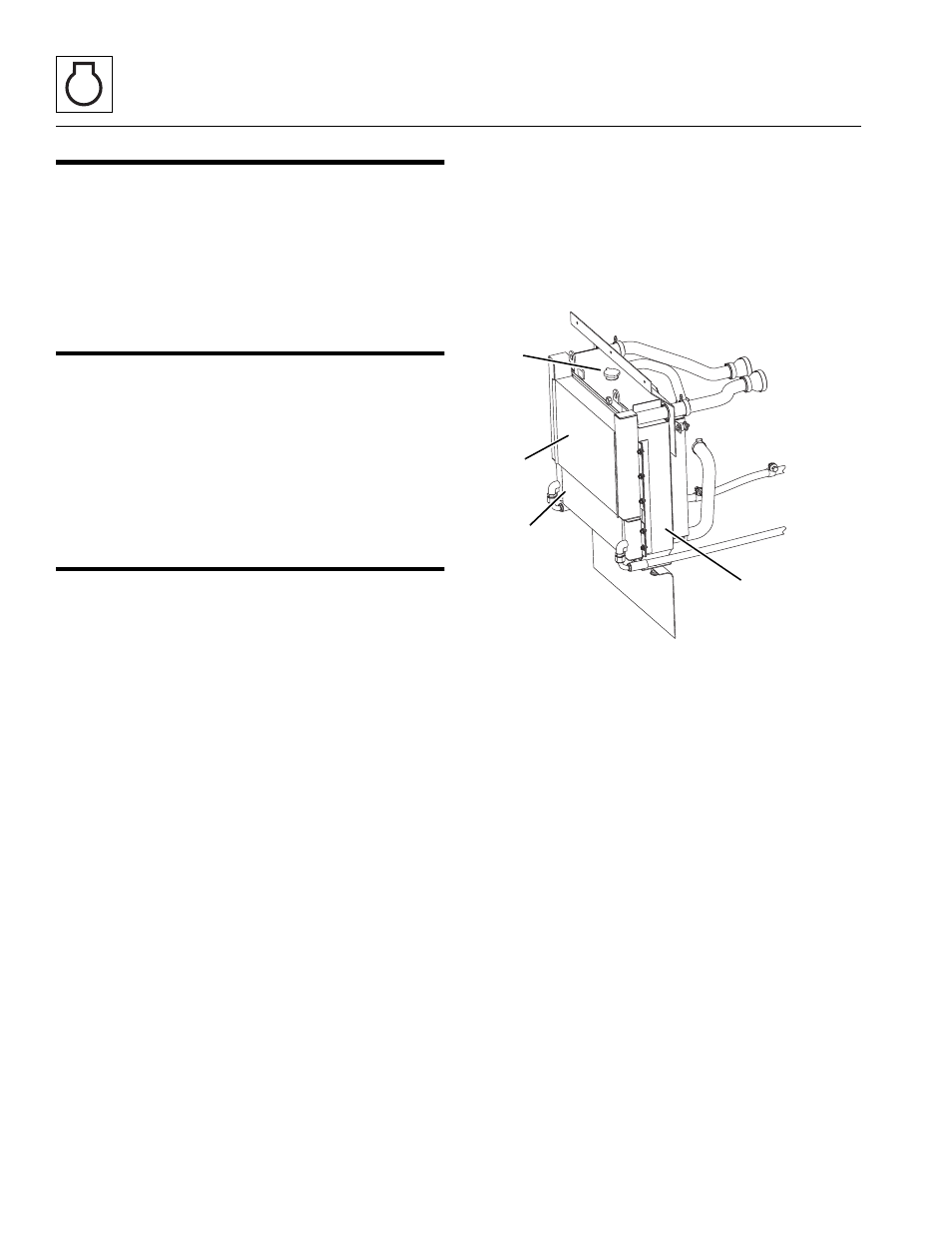

7.4.2

Radiator/Oil Cooler and Replacement

Before considering radiator or oil cooler replacement for

other than obvious damage, conduct a cooling system

pressure test check the coolant specific gravity, coolant

level, fan belt tension and dash panel temperature

indicator.

• If the engine runs hot, check the temperature of

the upper radiator hose.

• If the hose is not hot, the thermostat may be

stuck in the closed position.

• If the engine has overheated, performance may

suffer, indicating other damage including a leaking

cylinder head gasket, cracked cylinder head or

block, and/or other internal engine damage.

a. Radiator/Oil Cooler Removal

1. Park the machine on a firm, level surface, level the

machine, fully retract the boom, lower the boom,

place the travel select lever in the (N) NEUTRAL

position, engage the parking brake, and shut the

engine OFF.

2. Place a Do Not Operate Tag on both the ignition key

switch and steering wheel, stating that the machine

should not be operated.

3. Open the side and rear engine doors. Allow the

system fluids to cool.

4. Disconnect the battery positive (+) and negative (-)

cables from the appropriate battery terminals.

Remove the battery or batteries.

5. Slowly turn the radiator cap (1) to the first stop and

allow any pressure to escape. Remove the radiator

cap.

6. Place a suitable container beneath the radiator

drain.

7. Place a funnel at the base of the radiator to channel

the drained coolant into a container. Loosen the

drain petcock and slowly allow the coolant to drain.

Transfer the coolant into a properly labeled

container. Dispose of properly if coolant needs to be

replaced. Tighten the radiator drain petcock.

8. Label and disconnect all hoses and tubes attached

to the radiator (2), charge air cooler (3) and oil cooler

(4).

9. Working at the rear of the machine, remove the

capscrews and lockwashers securing the radiator

assembly.

10. Remove the radiator assembly through the rear of

the machine.

b. Radiator/Oil Cooler Installation

1. Secure the radiator (2), charge air cooler (3) and oil

cooler (4) to the machine frame with the previously

used hardware.

MAQ0290

1

4

2

3