Functional troubleshooting, Heat controller, inc. hbh series iom manual – Comfort-Aire HBH Series 6-10 Tons User Manual

Page 43

Heat Controller, Inc.

HBH SERIES

IOM Manual

42

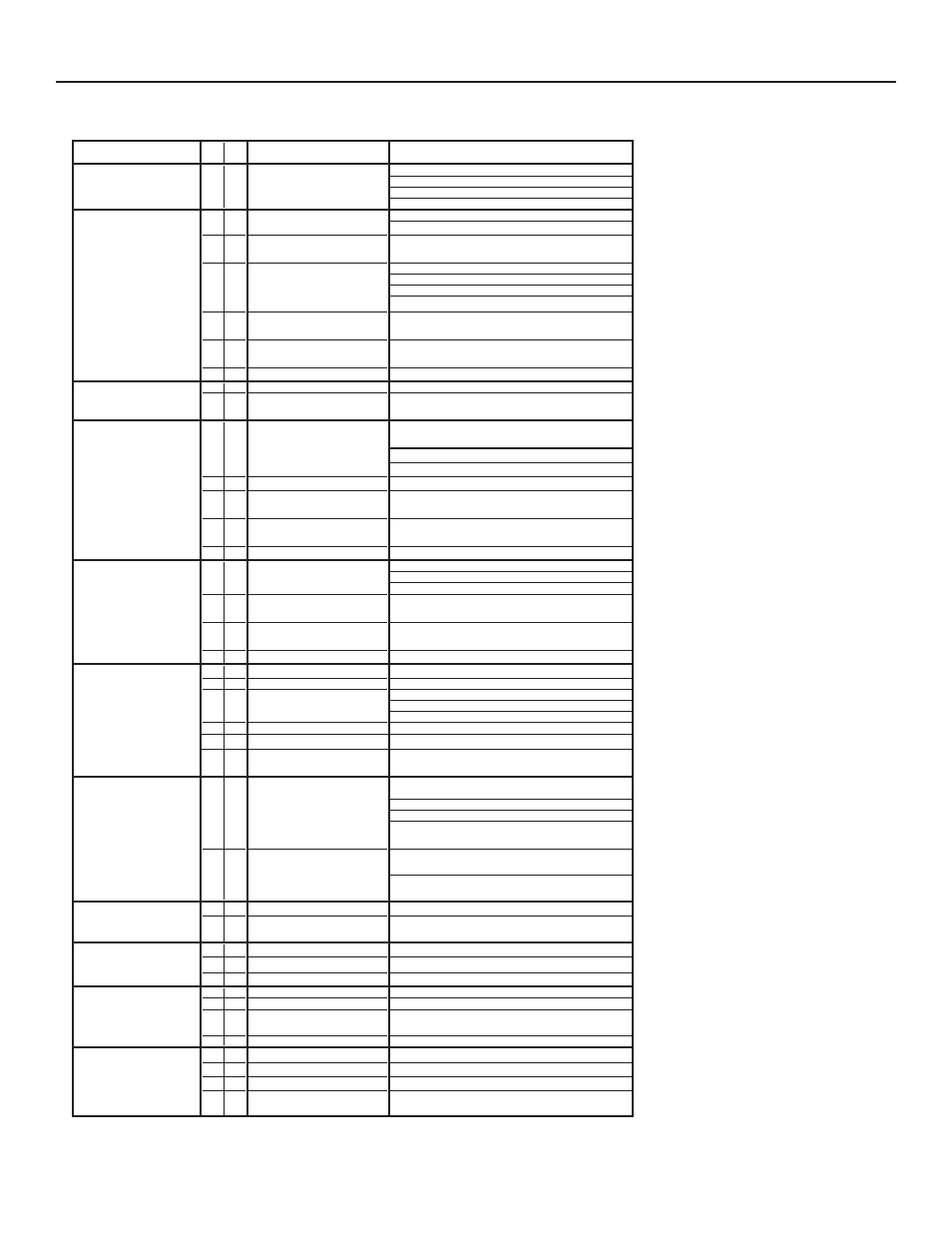

Functional Troubleshooting

Fault

Htg Clg Possible Cause

Solution

Main power Problems

X

X

Green Status LED Off

Check Line Voltage circuit breaker and disconnect

Check for line voltage between L1 and L2 on the contactor

Check for 24VAC between R and C on CXM/DXM

Check primary/secondary voltage on transformer

HP Fault-Code 2

X

Reduced or no water flow

Check pump operation or valve operation/setting

High pressure

in cooling

Check water flow adjust to proper flow rate

X

Water Temperature out of range in

cooling

Bring water temp within design parameters

X

Reduced or no Air flow

Check for dirty air filter and clean or replace

in heating

Check fan motor operation and airflow restrictions

Dirty Air Coil- construction dust etc.

Too high of external static. Check static vs blower table

X

Air Temperature out of range in

heating

Bring return air temp within design parameters

X

X

Overcharged with refrigerant

Check superheat/subcooling vs typical operating condition

table

X

X

Bad HP Switch

Check switch continuity and operation. Replace

LP/LOC Fault-Code 3

X

X

Insufficient charge

Check for refrigerant leaks

Low Pressure/Loss of Charge

X

Compressor pump down at start-

up

Check charge and start-up water flow

FP1 Fault - Code 4

X

Reduced or no water flow

Check pump operation or water valve operation/setting

Water Coil low

temperature limit

in heating

Plugged strainer or filter. Clean or replace.

Check water flow adjust to proper flow rate

X

Inadequate anti-freeze level

Check antifreeze density with hydrometer

X

Improper temperature limit setting

(30°F vs 10°F [-1°C vs -12°C])

Clip JW3 jumper for antifreeze (10°F [-12°C]) use

X

Water Temperature out of range

Bring water temp within design parameters

X

X

Bad thermistor

Check temp and impedance correlation per chart

FP2 fault - Code 5

X

Reduced or no Air flow

Check for dirty air filter and clean or replace

Air Coil low

temperature limit

in cooling

Check fan motor operation and airflow restrictions

Too high of external static. Check static vs blower table

X

Air Temperature out of range

Too much cold vent air? Bring entering air temp within

design parameters

X

Improper temperature limit setting

(30°F vs 10°F [-1°C vs -12°C])

Normal airside applications will require 30°F [-1°C] only

X

X

Bad thermistor

Check temp and impedance correlation per chart

Condensate Fault-Code 6

X

X

Blocked Drain

Check for blockage and clean drain

X

X

Improper trap

Check trap dimensions and location ahead of vent

X

Poor Drainage

Check for piping slope away from unit

Check slope of unit toward outlet

Poor venting. Check vent location

X

Moisture on sensor

Check for moisture shorting to air coil

Over/Under Voltage-

Code 7

X

X

Under Voltage

Check power supply and 24VAC voltage before and during

operation.

(Auto resetting)

Check power supply wire size

Check compressor starting. Need hard start kit?

Check 24VAC and unit transformer tap for correct power

supply voltage

X

X

Over Voltage

Check power supply voltage and 24VAC before and during

operation.

Check 24VAC and unit transformer tap for correct power

supply voltage

Unit Performance

Sentinel-Code 8

X

Heating mode FP2>125°F [52°C] Check for poor air flow or overcharged unit.

X

Cooling Mode FP1>125°F [52°C]

OR FP2< 40ϒF [4ϒC]

Check for poor water flow, or air flow

No Fault Code Shown

X

X No compressor operation

See "Only fan operates"

X

X Compressor Overload

Check and Replace if necessary

X

X Control board

Reset power and check operation

Unit Short Cycles

X

X Dirty Air Filter

Check and Clean air filter

X

X Unit in "Test Mode"

Reset power or wait 20 minutes for auto exit.

X

X Unit selection

Unit may be oversized for space. Check sizing for actual

load of space.

X

X Compressor Overload

Check and Replace if necessary

Only Fan Runs

X

X Thermostat position

Insure thermostat set for heating or cooling operation

X

X Unit locked out

Check for lockout codes. Reset power.

X

X Compressor Overload

Check compressor overload. Replace if necessary.

X

X Thermostat wiring

Check thermostat wiring at heat pump. Jumper Y and R

for compressor operation in test mode.

Plugged Air Filter

Restricted Return Air Flow

X

X

X

X

Replace Air Filter

Find & eliminate restriction. Increase return duct

and/or grille size.