Water-loop heat pump applications, Horizontal installation, Heat controller, inc. hbh series iom manual – Comfort-Aire HBH Series 6-10 Tons User Manual

Page 13: Figure 8: typical water-loop application, Figure 3: typical horizontal unit installation

Heat Controller, Inc.

HBH SERIES

IOM Manual

12

Water-Loop Heat Pump Applications

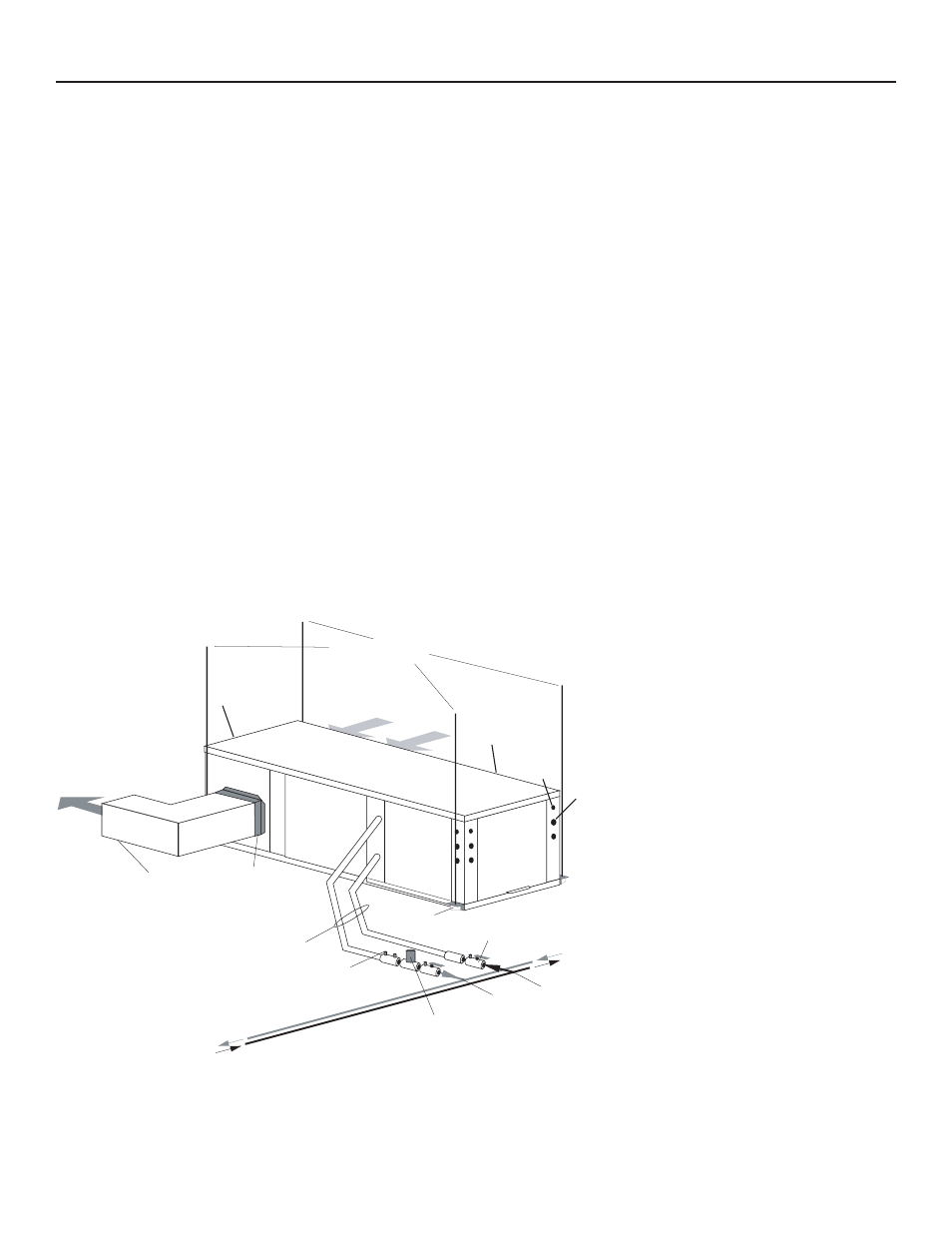

Figure 8: Typical Water-Loop Application

(by others)

Thermostat

Wiring

Insulated supply duct with

at least one 90 deg elbow

to reduce air noise

Return Air

Supply Air

Unit Hanger

3/8" [10mm] threaded rods

Flexible Duct

Connector

Optional

Balancing Valve

Water Out

Optional Low Pressure Drop Water

Control Valve

(can be internally mounted

on some models)

Stainless steel braid hose

with integral ÒJÓ swivel

Building

Loop

HORIZONTAL INSTALLATION

Figure 3: Typical Horizontal Unit Installation

Water In

Ball valve with optional

integral P/T plug

Unit

Power

CAP

CAP

EAP

BSP

CBP

Commercial Water Loop Applications -

Commercial systems typically include a number of units

connected to a common piping system. Any unit plumbing

maintenance work can introduce air into the piping system;

therefore air elimination equipment is a major portion of the

mechanical room plumbing. In piping systems expected to

utilize water temperatures below 50°F [10°C], 1/2” (13mm)

closed cell insulation is required on all piping surfaces to

eliminate condensation (extended range units required).

Metal to plastic threaded joints should never be used due to

their tendency to leak over time. All commercial class units

include low temperature-soldered bracket-supported IPT

water connections, which do not require a backup wrench.

Teflon tape thread sealant is recommended to minimize

internal fouling of the heat exchanger. Do not over tighten

connections and route piping so as not to interfere with

service or maintenance access. Hose kits are available

from Heat Controller in different configurations as shown

in Figure 8 for connection between the unit and the piping

system. Depending upon selection, hose kits may include

shut off valves, P/T plugs for performance measurement,

high pressure stainless steel braided hose, “Y” type strainer

with blow down valve, and/or “J” type swivel connection.

Balancing valves and an external low pressure drop solenoid

valve for use in variable speed pumping systems may also

be included in the hose kit.

The piping system should be flushed to remove dirt, piping

chips, and other foreign material prior to operation (see

“Piping System Cleaning and Flushing Procedures” in this

manual). The flow rate is usually set between 2.25 and 3.5

gpm per ton [2.9 and 4.5 l/m per kW] of cooling capacity.

Heat Controller recommends 3 gpm per ton [3.9 l/m per kW]

for most applications of water loop heat pumps. To insure

proper maintenance and servicing, P/T ports are imperative

for temperature and flow verification, as well as performance

checks.

Water loop heat pump (cooling tower/boiler) systems

typically utilize a common loop, maintained between 60 -

90°F [16 - 32°C]. The use of a closed circuit evaporative

cooling tower with a secondary heat exchanger between the

tower and the water loop is recommended. If an open type

cooling tower is used continuously, chemical treatment and

filtering will be necessary.

Low Water Temperature Cutout Setting

- CXM Control

When antifreeze is selected, the FP1

jumper (JW3) should be clipped to

select the low temperature (antifreeze

10°F [-12.2°C]) set point and avoid

nuisance faults (see “Low Water

Temperature Cutout Selection” in this

manual).

Note: Low water temperature operation

requires extended range equipment.