Unit operating conditions, Heat controller, inc. hbh series iom manual, Based on 15% methanol antifreeze solution – Comfort-Aire HBH Series 6-10 Tons User Manual

Page 41

Heat Controller, Inc.

HBH SERIES

IOM Manual

40

Unit Operating Conditions

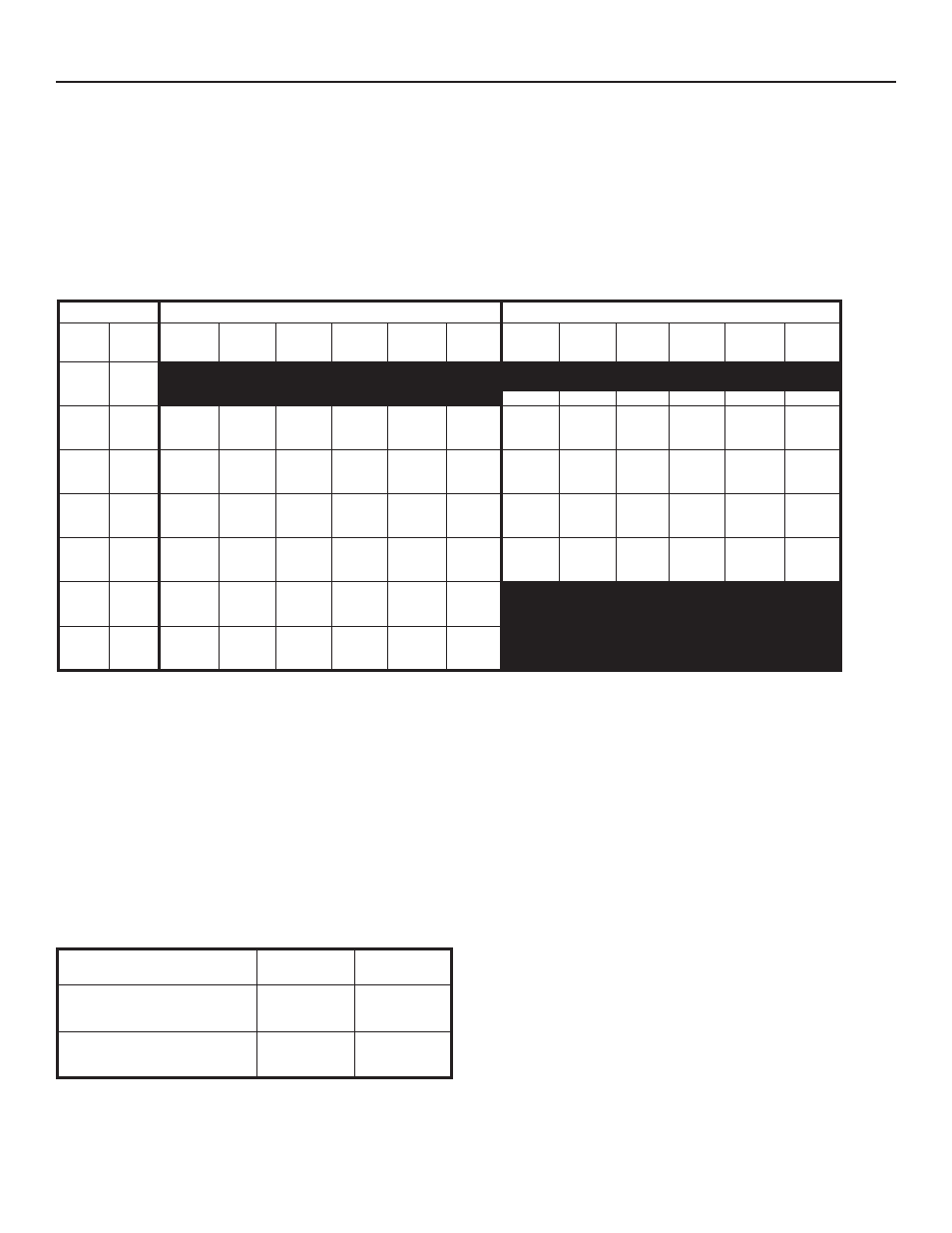

Table 11: HB Series Typical Unit Operating Pressures and Temperatures (60Hz - I.P. Units)

Operating Pressure/Temperature tables include the

following notes:

• Airflow is at nominal (rated) conditions;

• Entering air is based upon 70°F [21°C] DB in heating

and 80/67°F [27/19°C] in cooling;

• Subcooling is based upon head pressure at compressor

service port;

• Cooling air and water values can vary greatly with

changes in humidity level.

Cooling

Heating

Entering

Water

Temp °F

Water

Flow

GPM/ton

Suction

Pressure

PSIG

Discharge

Pressure

PSIG

Superheat

Subcooling

Water

Temp Rise

°F

Air Temp

Drop °F

DB

Suction

Pressure

PSIG

Discharge

Pressure

PSIG

Superheat Subcooling

Water

Temp Drop

°F

Air Temp

Rise °F DB

20

1.5

2.25

3

60 - 63

289 - 306

9 - 12

8 - 17

3 - 4

20 - 22

30

*

1.5

2.25

3

122 - 125

116 - 119

112 - 115

197 - 204

177 - 184

168 - 173

13 - 16

17 - 19

19 - 21

15 - 20

15 - 18

14 - 18

20 - 24

13 - 16

10 - 12

22 - 23

21 - 22

21 - 22

67 - 71

71 - 75

74 - 76

297 - 315

301 - 321

303 - 323

10 - 12

10 - 12

11 - 13

9 - 18

10 - 19

10 - 19

8 - 9

6 - 7

4 - 5

22 - 23

23 - 24

23 - 25

50

1.5

2.25

3

128 - 134

122 - 131

119 - 129

240 - 252

219 - 233

209 - 224

11 - 14

12 - 17

13 - 18

13 - 16

12 - 16

11 - 15

20 - 22

13 - 15

10 - 11

21 - 22

21 - 22

21 - 22

97 - 102

104 - 108

107 - 122

333 - 355

339 - 361

342 - 369

9 - 11

9 - 11

9 - 11

13 - 21

13 - 21

13 - 20

11 - 12

8 - 9

6 - 7

29 - 30

30 - 31

31 - 32

70

1.5

2.25

3

132 - 139

131 - 137

131 - 136

311 - 329

287 - 306

275 - 294

9 - 12

10 - 13

10 - 13

12 - 15

10 - 12

9 - 11

19 - 21

13 - 14

9 -11

20 - 21

20 - 21

20 - 21

130 - 135

139 - 144

145 - 149

367 - 392

375 - 402

380 - 407

9 - 11

10 - 11

10 - 11

13 - 21

13 - 20

13 - 19

14 - 16

10 - 12

8 - 9

35 - 37

37 - 38

38 - 39

90

1.5

2.25

3

137 - 144

135 - 142

135 - 141

400 - 420

373 - 395

359 - 383

8 - 10

9 - 11

9 - 12

13 - 16

10 - 12

9 - 11

19 - 20

12 - 14

9 - 10

19 - 20

19 - 20

19 - 20

164 - 169

175 - 178

179 - 187

401 - 430

411 - 442

415 - 455

10 - 13

12 - 16

13 - 18

13 - 17

14 - 17

14 - 16

18 - 20

12 - 14

9 - 11

41 - 43

43 - 45

44 - 46

100

1.5

2.25

3

139 - 147

138 - 146

138 - 146

448 - 471

420 - 445

405 - 432

8 - 9

8 - 10

8 - 10

13 - 16

11 - 13

10 - 11

18 - 20

12 - 13

9 - 10

18 - 19

18 - 19

18 - 19

120

1.5

2.25

3

144 - 153

143 - 153

143 - 152

549 - 583

525 - 557

511 - 543

7 - 8

7 - 8

8 - 9

15 - 17

12 - 14

11 - 13

17 - 19

11 - 13

9 - 10

17 - 18

17 - 18

17 - 18

*Based on 15% Methanol antifreeze solution

NOTE: The tables include the following notes:

•

Airflow is at nominal (rated) conditions;

•

Entering air is based upon 70°F [21°C] DB in heating and

80/67°F [27/19°C] in cooling;

•

Subcooling is based upon head pressure at compressor

service port;

•

Cooling air and water values can vary greatly with

changes in humidity level.

Table 12: Water Temperature Change Through Heat

Exchanger

Water Flow, gpm [l/m]

Rise, Cooling

°F, [°C]

Drop, Heating

°F, [°C]

For Closed Loop: Ground Source or

Closed Loop Systems at 3 gpm per

ton [3.2 l/m per kW]

9 - 12

[5 - 6.7]

4 - 8

[2.2 - 4.4]

For Open Loop: Ground Water

Systems at 1.5 gpm per ton

[1.6 l/m per kW]

20 - 26

[11.1 - 14.4]

10 - 17

[5.6 - 9.4]