Introduction, Principles of operation, 1 general description – Pulsafeeder PulsaPro 900 EN User Manual

Page 5: 1 overall operation

1

1. Introduction

1.1 General

Description

Diaphragm Metering pumps are positive displacement reciprocating pumps that combine the

high efficiency of the plunger pump with a sealed diaphragm that prevents product leakage.

Each pump consists of a power end and a process end separated by a hydraulically operated

diaphragm. Individual pumps will vary in appearance due to various liquid ends, accessories,

and multiplexing - however, the basic principles of operation remain the same.

2. Principles

of

Operation

2.1 Overall

Operation

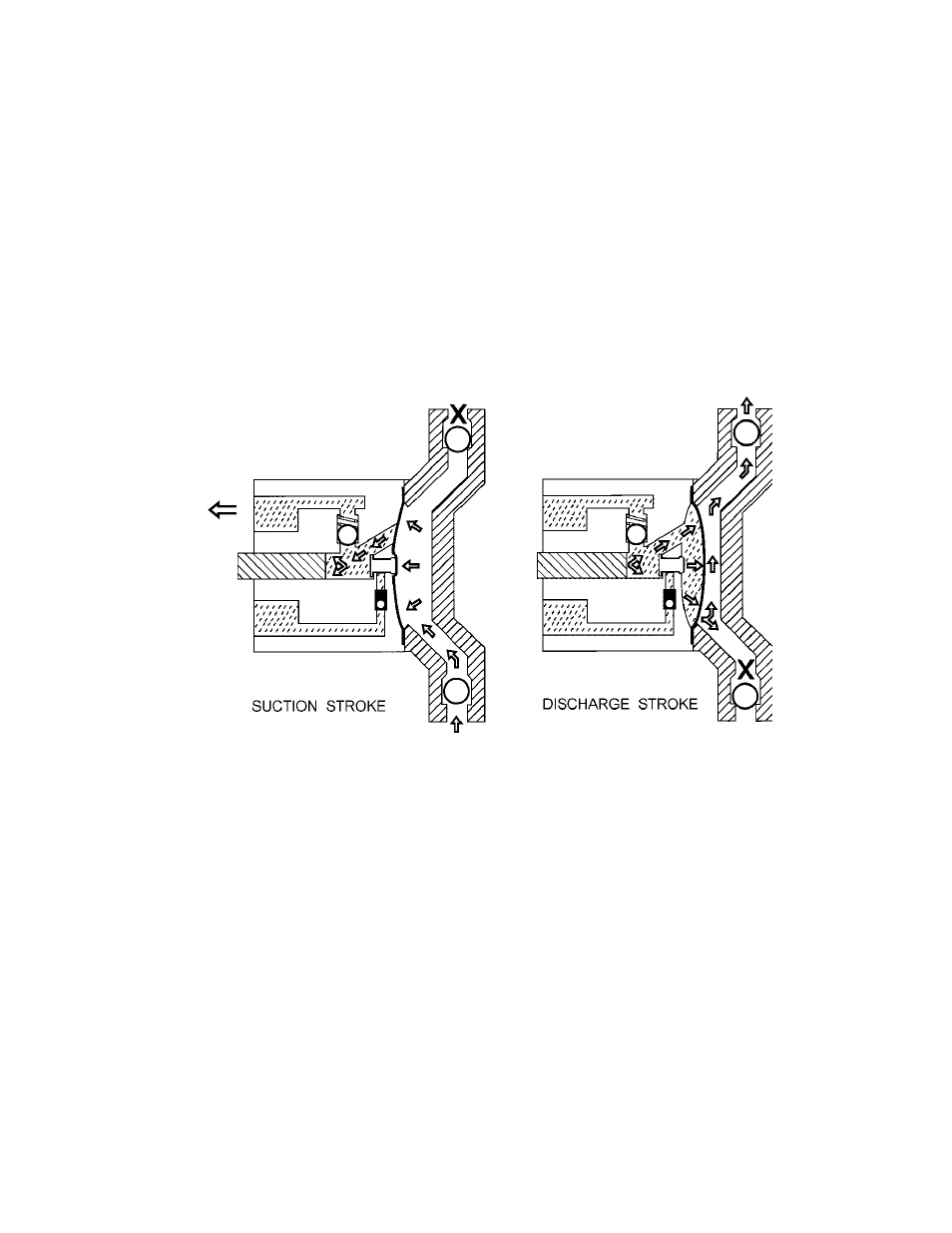

Figure 1

A piston reciprocates within an accurately sized cylinder at a preset stroke length, displacing

an exact volume of hydraulic fluid. The hydraulic fluid acts against a sealed diaphragm,

which pumps the chemicals.

The piston and associated mechanisms are enclosed by a chamber called the Pump Head or

intermediate housing. This also acts as a hydraulic oil reservoir.

The diaphragm separates the hydraulic oil from the product pumped. The diaphragm moves

in exact response to the piston displacement. The diaphragm does no work, and acts only as a

separator.

The displacement of the oil is translated into an equal displacement of the chemical being

pumped. Therefore, piston retraction causes the product to enter through the suction check

valve. Piston advance causes the discharge of an equal amount of the product through the

discharge check valve.