3 piping system – Pulsafeeder PulsaPro 900 EN User Manual

Page 14

10

5.3 Piping

System

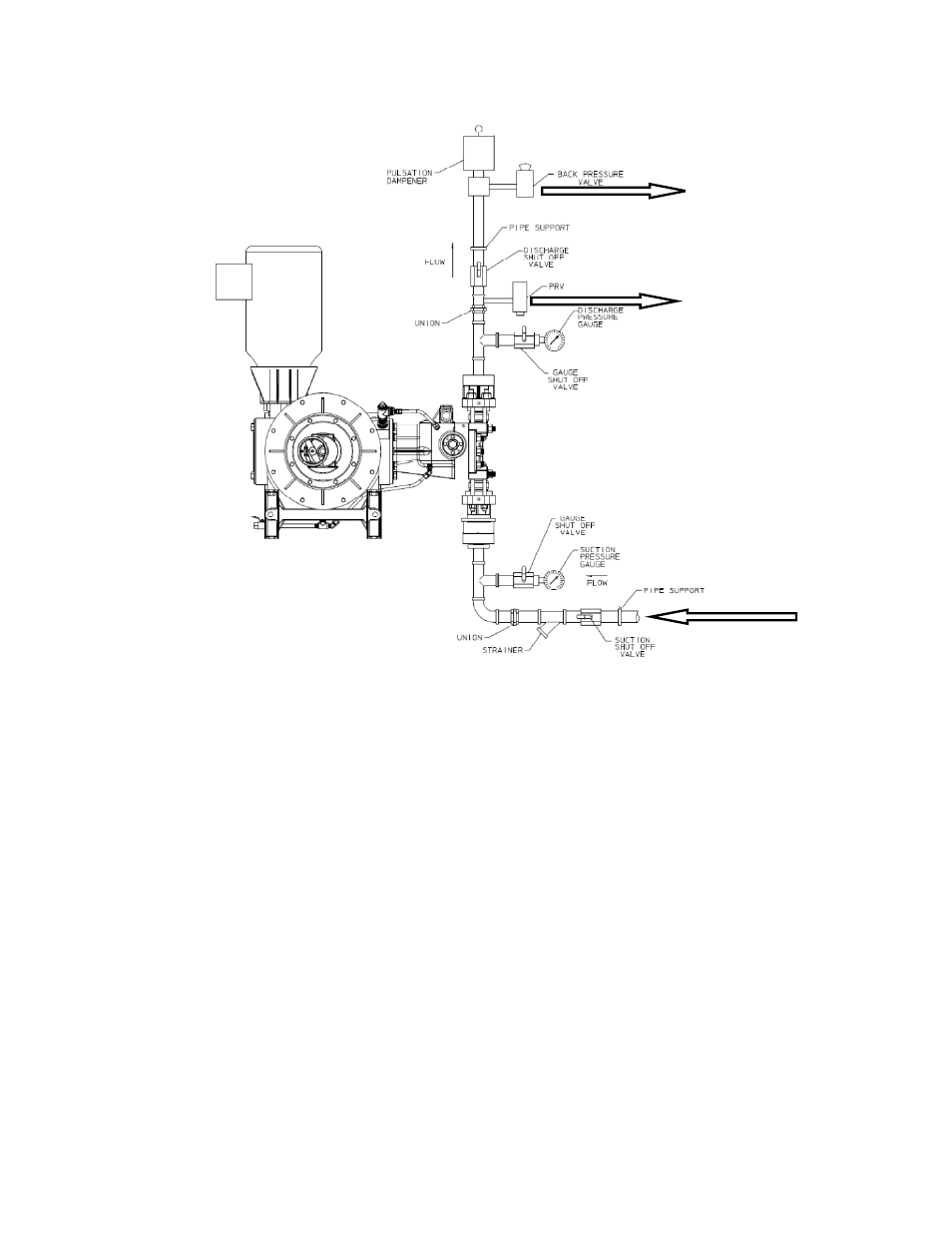

Figure 8A

All piping systems should include:

1. Shutoff valves and unions (or flanges) on suction and discharge piping.

a) This permits check valve inspection without draining long runs of piping.

b) Shutoff valves should be of the same size as connecting pipe.

c) Ball valves are preferred since they offer minimum flow restriction.

2. An inlet strainer, if the process fluid is not a slurry.

a) Pump check valves are susceptible to dirt and other solid contaminants unless designed

for that service, and any accumulation can cause malfunction.

b) The strainer should be located between the suction shutoff valve and the pump suction

valve.

c) It must be sized to accommodate the flow rate and the anticipated level of contamination.

d) 100 mesh screen is recommended.

3. Vacuum/pressure gauges in the suction and discharge lines in order to check system operation.

a) Gauges should be fitted with protective shutoff valves for isolation while not in use.

DISCHARGE

RETURN TO TANK

FROM SUPPLY TANK