1 pulsalarm leak detection diaphragm, 2 leak detection – setup for pressure – Pulsafeeder PulsaPro 900 EN User Manual

Page 48

44

9.1

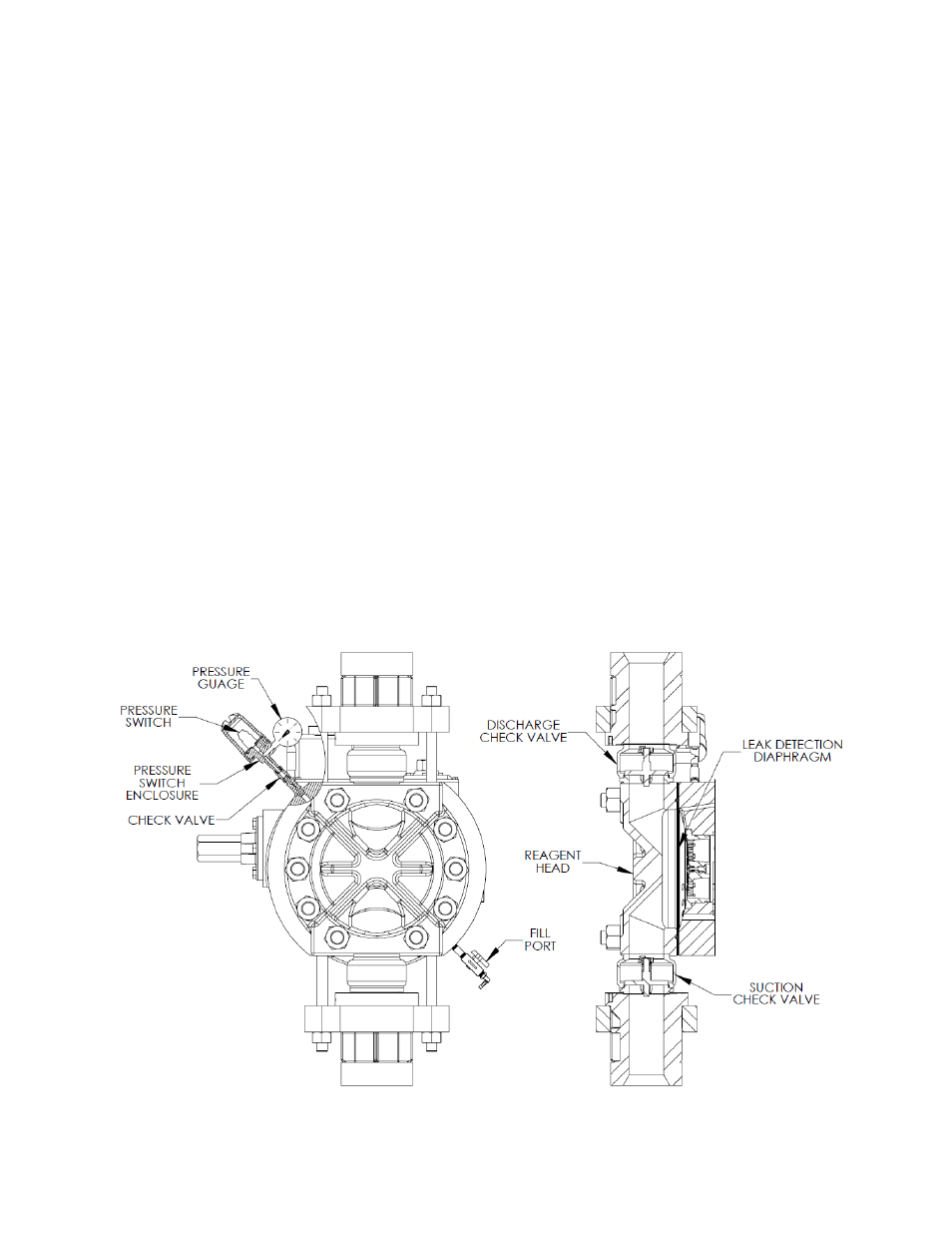

PULSAlarm Leak Detection Diaphragm

Double, or sandwiched, TFE diaphragms are sealed at their peripheries to an intermediate

metal spacer ring. The space between the diaphragms is sealed so that the diaphragm

functions in a manner similar to a standard single diaphragm. In the pressure system, the

space between the diaphragms is filled with a small amount of fluid. At startup, any excess

fluid in the system is expelled through the check valve. Once the excess is removed the

system is capped and sealed. The fluid as supplied from the factory is Silicone LD, but an

alternate fluid can be used if compatibility with the materials of construction is verified. This

space is connected to an adjustable electrical switch (optional) that actuates in response to

buildup of pressure resulting from rupture of either or both diaphragms. Switch operation can

be used to perform any external function, typically to signal an alarm or turn off the pump.

For component location refer to Figure 24.

9.2

Leak Detection – Setup for Pressure

Pumps incorporating pressure leak detection are shipped from the factory with the system fully

set up to work at full pump pressure. No further setup is required. The standard factory barrier

fluid is Silicone LD, if any other customer-specified media is used it must be compatible with

construction materials. The system will require proper setup after maintenance or repairs see

section 9.3 on the following page for the proper procedure.

Figure 25