1 ptp (push to purge) valve – Pulsafeeder PulsaPro 900 EN User Manual

Page 36

32

the setting is too low the valve will operate on each discharge stroke. This results in decreased

pumping capacity and will eventually affect the efficiency of the valve.

To check the hydraulic bypass pressure setting, install a gauge and a back pressure valve in the

pump discharge line. The gauge must be between the pump and the back pressure valve (for

convenience, locate the two as close to the pump as possible). With the pump operating at

maximum stroke length, gradually increase the discharge pressure and observe when the HBV

starts to operate through the diagnostic window. The cracking pressure of the valve must be at

least as high as the maximum pressure of the system but no more than 10% over the pump’s

rated pressure. After adjustment tighten the lock nut and reinstall the metal cover.

Periodic inspection of the valve seat is recommended. If it becomes worn or damaged leakage

will occur regardless of how tightly the valve is adjusted.

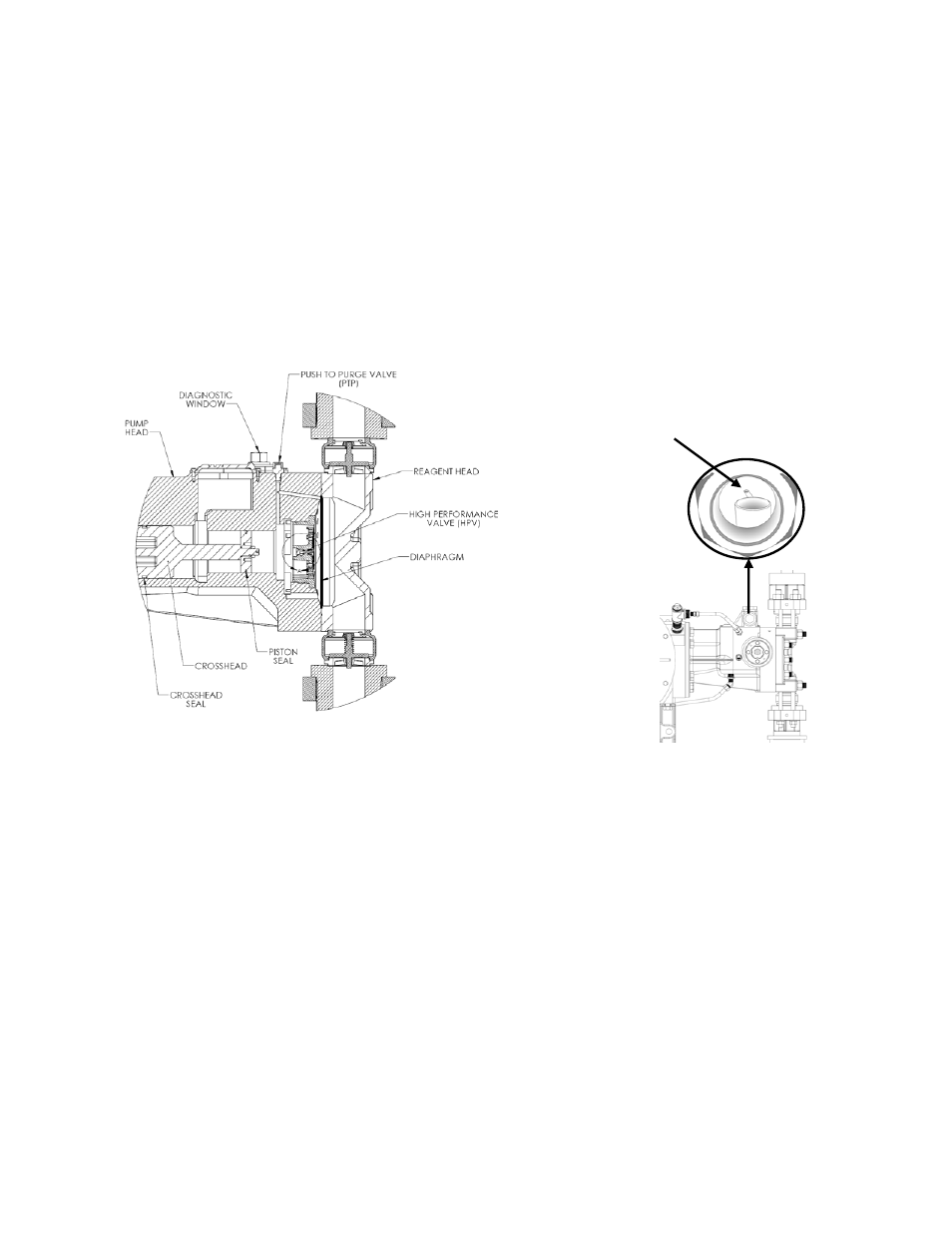

7.5.1

PTP (Push To Purge) Valve

Figure 18

The PTP (Push to Purge) Valve is a gravity-operated disk check valve that automatically

removes gases from the hydraulic system. On each discharge stroke of the pump, pressure

generated by the piston lifts the disk off a lower seat. If accumulated gasses are present the

gasses flow around the disk and are vented to the reservoir. If there are no gasses present

then oil forces the disk to shut off against an upper seat – limiting the amount of fluid that

escapes. On each suction stroke, the disk returns (by gravity) to the lower seat to prevent

reentry of gas into the system. By this mechanism, under normal operation, a small amount

of oil is displaced with each discharge stroke. This oil is returned by gravity to the reservoir

where it is recycled. The PTP removes minute accumulations of gas long before they are

visible or detrimental to pump operation.

The PTP includes a spring-loaded button at the top of the valve that is used to accelerate the

purging of accumulated gasses in the hydraulics. Holding the button down momentarily

opens the disk valve so that large amounts of gas and hydraulic fluid can be instantly purged.

When the button is released, the valve returns to normal automatic operation. PTP operation

can be monitored by observing oil flow through the small tube behind the diagnostic window.

OBSERVE

PTP FLOW

HERE