1 re-filling the hydraulic system, 2 re-priming the hydraulic system – Pulsafeeder PulsaPro 900 EN User Manual

Page 29

25

7.2.1

Re-Filling the Hydraulic System

Use the following procedure to refill the Hydraulic System after Diaphragm/Piston service or

extreme system upset conditions:

1. Disconnect the power source to the drive motor (e.g., lockout/tagout the motor disconnect).

2. Check the Pump Head Oil Level (refer to Section 6.1.3 Oil Changes). Restore levels in the

Pump Head Reservoir if necessary.

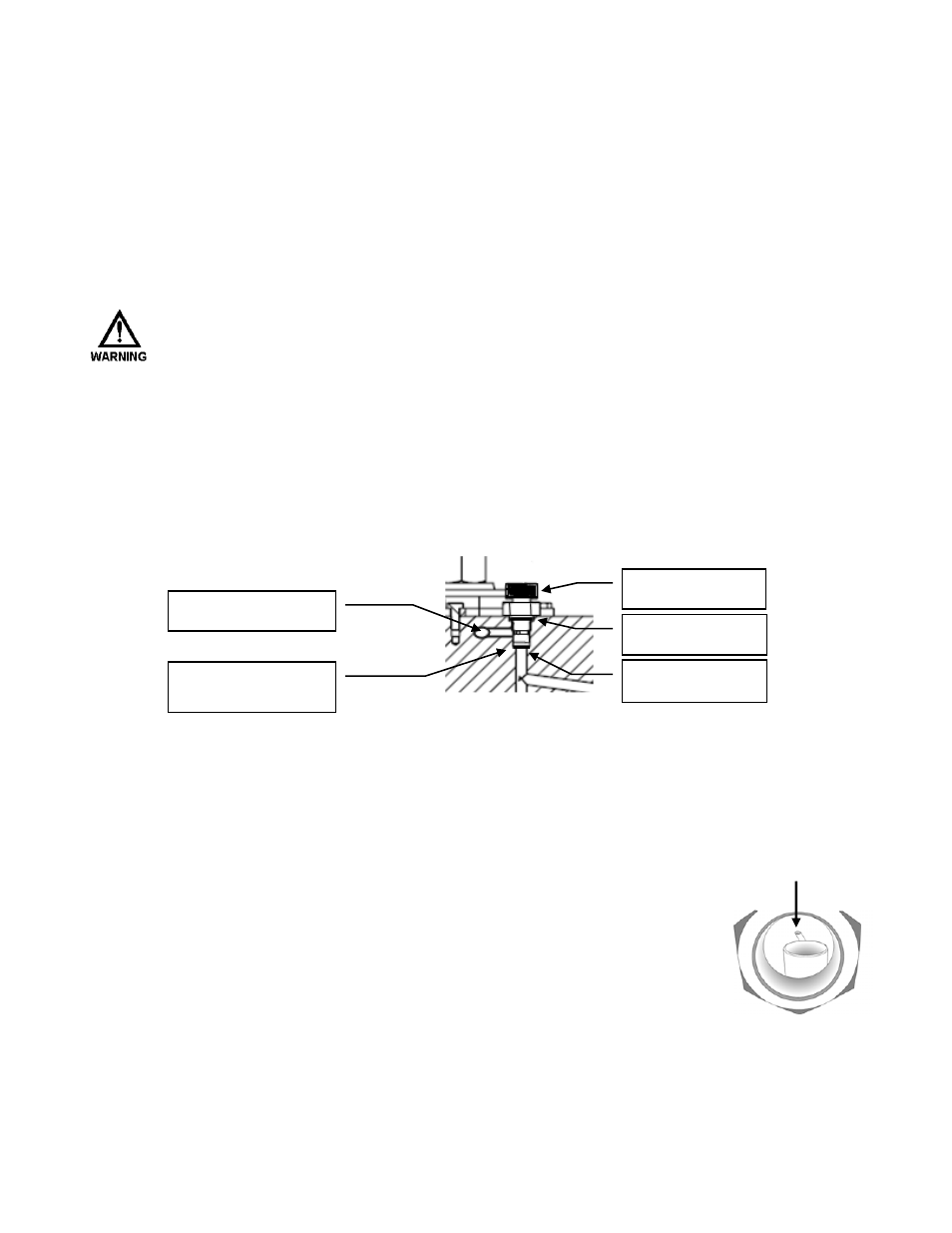

3. Remove the PTP valve from the Pump Head carefully to access the Hydraulic Chamber. There is

an o-ring and copper gasket that need to be properly handled and protected from damage.

O

IL MAY LEAK OUT FROM AROUND THE

PTP

VALVE

.

T

AKE APPROPRIATE MEASURES

TO CAPTURE AND CONTAIN IT

.

4. Set the stroke length adjustment to 0%.

5. Using a small plastic funnel (or a kitchen style turkey baster), slowly pour PULSAlube Universal

1HG (or oil specific to your application) into the Hydraulic Chamber through the PTP valve port

until full. Make sure the neck of the funnel enters the small hole at the bottom of the threaded

bore. Failure to do so will result in the oil running through a small cross drilled hole into the

Reservoir instead of the Hydraulic Chamber.

6. Replace the PTP valve, ensuring that the flat copper gasket and o-ring are properly in place.

7.2.2

Re-Priming the Hydraulic System

Use the following procedure to re-prime the Hydraulic System:

1. Restore power to the pump.

2. Turn on the pump and slowly adjust the stroke length to 50%.

3. Allow the pump to operate for 30 minutes. During this time fully depress and

hold the PTP valve button for several seconds every 5 minutes. After

approximately 15 minutes oil should begin to flow out of the small diagnostic

port (refer to Figure 13) but may appear foamy. By the end of the 30 minute

period oil coming out of the diagnostic port should be clear of bubbles.

Depending on the system discharge flow and pressure oil may spurt from the

diagnostic port. This is normal.

4. Adjust the stroke length to 100%. Confirm the pump is making the proper flow and pressure

using external equipment - a flow meter and pressure gage for example.

5. If the pump is NOT making flow and pressure repeat this re-priming procedure.

6. If, after attempting a second re-prime, the pump still doesn’t make flow and pressure, repeat the

Re-Fill and Re-Prime procedures above.

Copper Gasket

O-Ring

PTP

OBSERVE

PTP FLOW

HERE

Cross Drilled Hole

Funnel Neck must

Enter Here