3 check valves – Pulsafeeder PulsaPro 900 EN User Manual

Page 30

26

7.3 Check

Valves

Most fluid metering problems are related to check valves. Problems can be caused by solids

accumulation between the valve and seat, corrosion of seating surfaces, erosion, physical

damage due to wear or the presence of foreign objects.

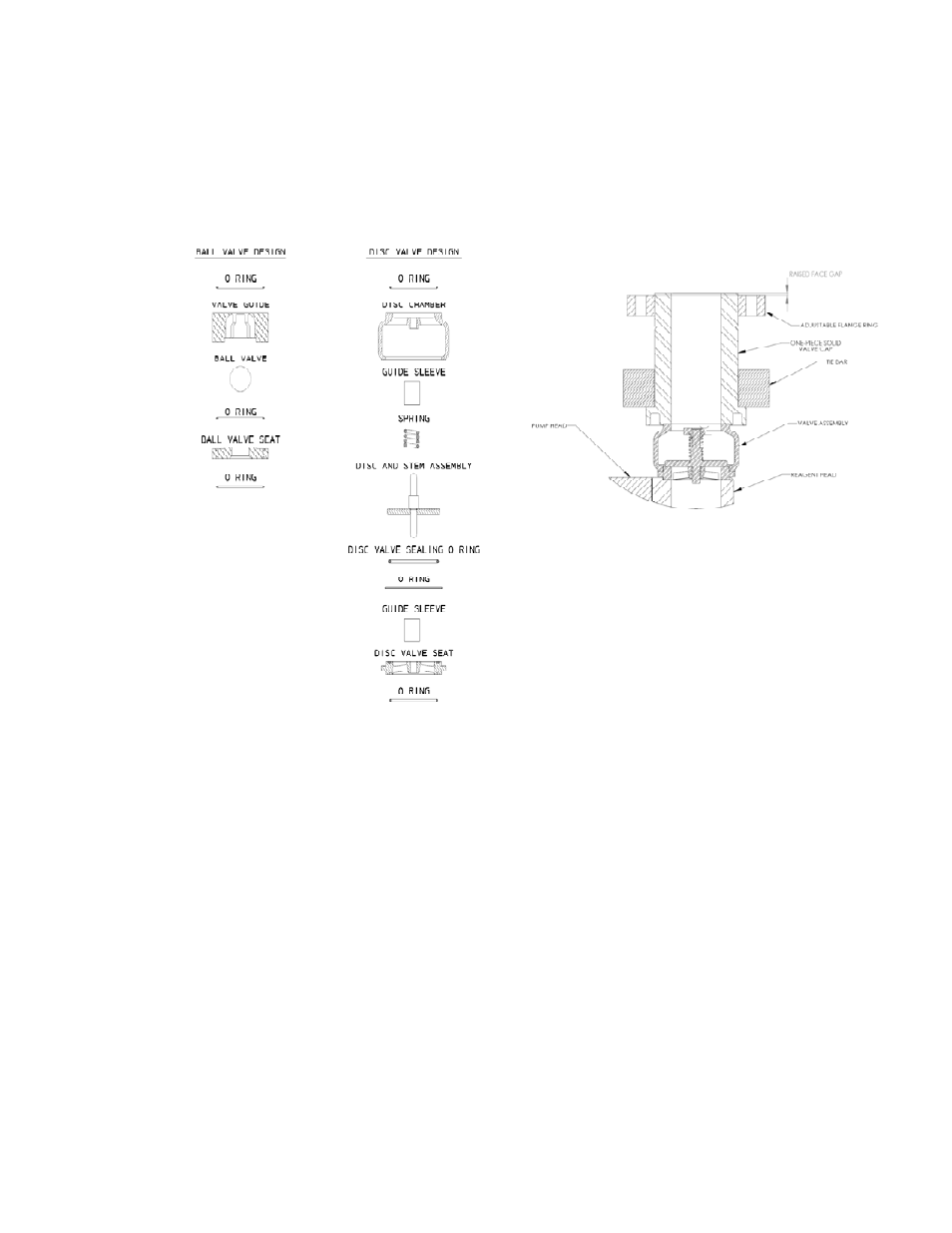

There are two styles of check valves. Ball checks are used for lower flows. Disk checks are

used for higher flows.

Figure 14

The ball check valve incorporates a ball, guide, and seat. Flow in the unchecked direction

lifts the ball off the seat, allowing liquid to pass through the guide. Reverse flow forces the

ball down, sealing it against the sharp edge of the seat. The guide permits the ball to rotate

but restricts vertical and lateral movement in order to minimize “slip” or reverse flow. Ball

rotation prolongs life by distributing wear over the entire surface of the ball. Since ball return

is by gravity, the valve must be in the vertical position in order to function properly. Parts are

sealed by o-rings.

The disk valve functions in the same manner as the ball valve, except that the ball is replaced

by a spring-loaded guided disk. The seat may contain a captured o-ring to facilitate sealing.