Installation and start-up – Blodgett SN-G Series User Manual

Page 11

OM-SN-G 9

Installation and Start-Up

5.

Factory Stacked Units

This section is applicable only if you are installing factory-stacked units.

Installing stacked steamers is similar to installing a single unit. The steamers

are stacked and assembled at the factory and delivered with the water

connections and drain hoses required for a single point connection.

a.

Water Connection

The same water supply connection is used for both units. At the water

inlet valves, 3⁄4 inch female NH connectors (garden hose type) are

used for the water supplies. There are two connections to be made.

Treated water (softened) is connected to the right valve fitting (looking

from the rear of the unit) and untreated water to the left fitting.

b.

Electrical Supply Connection

Separate, individual electrical connections will be required for each

steamer in the stack. Each Steamer must have its own branch circuit

protection.

c.

Gas Connection

Separate gas connections are required for each steamer in the stack.

Gas supply must be adequate under all conditions as listed on page 9.

d.

Drain Connection

Steamers must be leveled front to back, or pitched to the rear

(maximum 1⁄4 inch) by adjusting the bullet feet on the stand. A 2 inch

ID hose may be attached to the unit drain. It must be rated for very hot

water.

Ensure that there is a free air gap between the end of the unit drain

and the building drain. This gap should be as close as possible to the

unit drain. Do not allow elbows or restrictions between the unit and the

free air gap.

Install the line with a constant downward pitch.

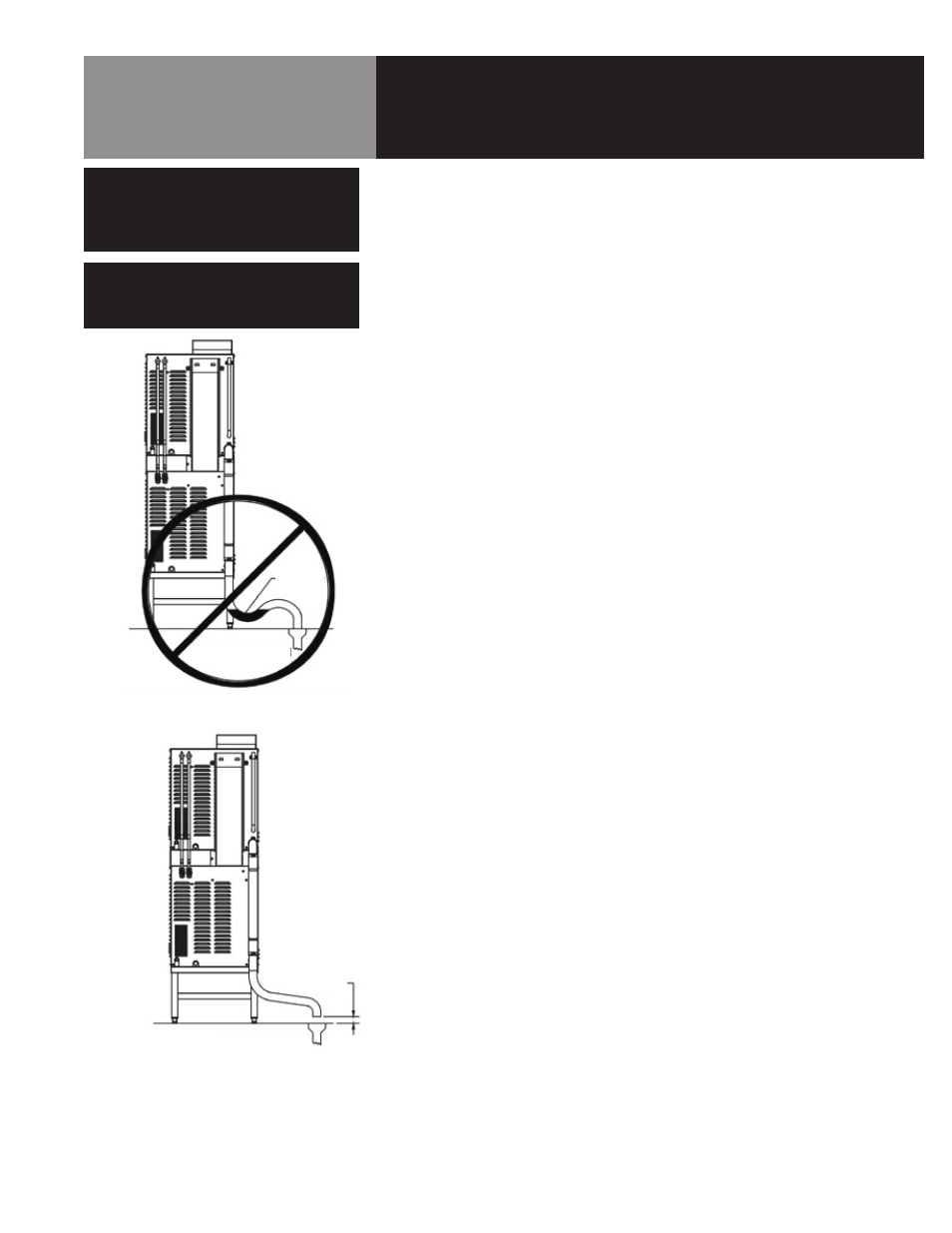

CAUTION

DO NOT USE PLASTIC PIPE. DRAIN MUST

BE RATED FOR VERY HOT WATER.

WARNING

DO NOT CONNECT THE DRAIN DIRECTLY

TO A BUILDING DRAIN. BLOCKING THE

DRAIN IS HAZARDOUS.

WATER

TRAP

BUILDING DRAIN

IMPROPER DRAIN LINE CONNECTION

PROPER DRAIN LINE CONNECTION

BUILDING DRAIN

AIR GAP

Proper Drain Line Connection:

Drain line must have a constant down-

ward pitch of at least 1/4” per foot.