Appendix “c” - applications (cont’d) – Red Lion LEGEND User Manual

Page 57

-55-

APPENDIX “C” - APPLICATIONS (Cont’d)

TYPICAL COUNTER/RATE APPLICATION

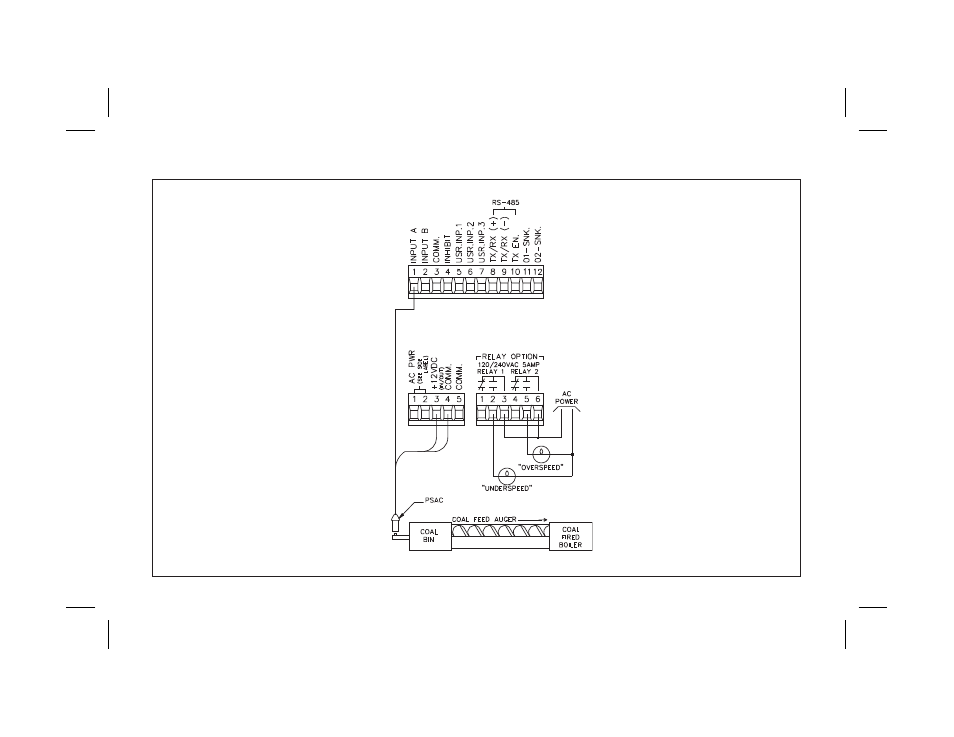

COAL FEED RATE & USAGE INDICATION

An industrial plant has an in-house coal fired boiler

that provides heating and powers an electric generator

used for secondary power. An auger feeds the coal into

the boiler furnace. The actual pressure of the boiler is

controlled by the feed rate of the auger. An indication is

required when the feed rate falls below or exceeds the

desired RPM levels. The plant manager also wants an

indication of the amount of coal that is used. The desired

auger revolution rate is between 25 and 35 RPM. A shaft

rotation speed of 30 RPM is equal to a feed rate of 1.8

tons of coal per hour. Rate and usage indication is to be in

10ths of tons per hour.

An PSAC can be used to sense a bolt head located on

the auger shaft. The count with direction x1 (CT =

DIRx1) is programmed in the program counter module

with input B left open to the unit counts in a positive

direction. The reset action mode is set to reset to zero and

the automatic reset is disabled. First the scaling required

for the counter is calculated.

The number of pulses must be calculated:

Number of pulses = # of rev x pulses per rev =

1 x 30 = 30 pulses/min (PPM)

Per hour = x time = 30 x 60 = 1800 PPH

The total scaling factor is calculated by the following

formula:

K

T

= Desired display units

¸ number of pulses =

18

¸ 1800 = 0.01

The Count Scale Factor (SF) is calculated using the

following formula and the scale multiplier is chosen using

the general rule (reference scaling for count indication):

SF = K

T

¸ SCM = 0.01 ¸ 0.1 = 0.1

The decimal point location for the count

display is programmed for 0.0.

At 30 RPM the pulse rate per minute is the same

since a single bolthead is being sensed once each

revolution. Since it takes one hour at 30 RPM to

u s e 1 . 8 t o n s o f c o a l , t h e n u mb e r o f p u l s e s

accumulated in that hour will be 1800 (30 PPM x

60 min/hr = 1800). The Scale Factor needed is

0.01 (SF = desired reading/# of pulses = 18/1800

= 0.01). The rate display is to indicate RPMs with

a resolution in tenths, The total scaling factor is

calculated by the following formula:

K

T

= Desired display units

¸ number of pulses =

300 RPM

¸ 30 = 10

The Rate Scale Factor (SF) is calculated using

the following formula and the scale mutiplier is

chosen using the general rule (reference scaling

for count indication):

SF = K

T

¸ SCM = 10 ¸ 10 = 1

It is then only necessary to program the Rate

Conversion Factor for Rate per Minute. Since the

application requires two presets for the upper and

lower limits, the outputs are programmed to the

Rate display. Both outputs are programmed for

boundary operation and output 1 is programmed

for “-” phase. The relay outputs are connected to

overspeed and underspeed indicator lights.