Appendix “c” - applications – Red Lion LEGEND User Manual

Page 56

-54-

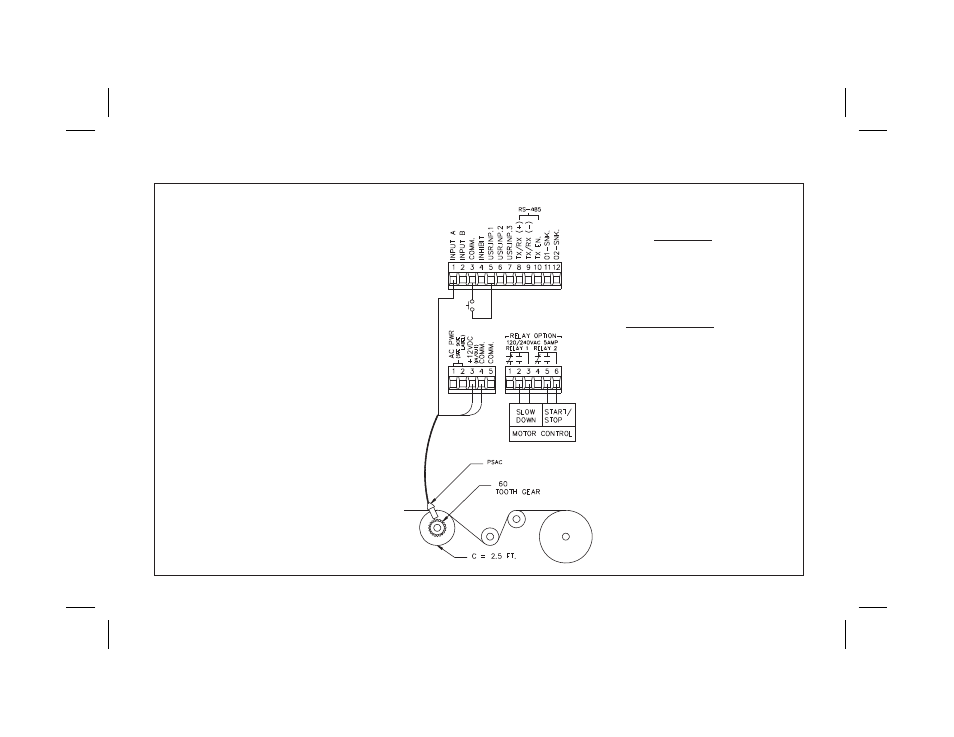

APPENDIX “C” - APPLICATIONS

DUAL PRESET COUNTING APPLICATION

A typical industrial application for a Legend unit

requires both a slow down output and a final stop

output. The Legend can be easily programmed to solve

this requirement. For instance, a textile web process

requires a dual output as the web progresses to the

proper length. A typical length of material for this

application is a 10,000 foot length. In this case, it

would be best to set the unit up for Manual Reset with

Preset tracking. Preset 2 is set at 10000 and Preset 1 set

for 9500. The counter causes the process to slow down

until 10,000 (preset 2) is reached at which point Output

2 would activate and latch for final stop. The advantage

of using Preset tracking is that when changing the total

length it is only necessary to change Preset 2 (length).

P r e s e t 1 ( s l o w d o w n ) w i l l ma i n t a i n t h e s a me

differential (500), assuming the same amount of slow

down is required. In the program counter module, the

continue mode is programmed for count with direction

x1 (CT=DIRx1) with input B disconnected so the unit

will count in a positive direction. The reset action mode

is set for reset to preset 2 and the automatic reset mode

is disabled. In the program options module the preset

tracking is enabled. User input function key F1 is set to

reset the count display and user input 1 is programmed

to set output 2 in case of an emergency stop. Outputs

one and two are assigned to the count display for latch

mode, and the reset with count is enabled.

The accompanying drawing shows an PSAC sensing

a 60 tooth gear which is attached to a 2.5 f t.

Circumference drum. Since the unit of measure is a foot,

the first step is to find the number of pulses per foot that

will be used.

The following formula is used.

Pulses/ft. = 60 pulses/rev. = 24 pulses/ft.

2.5 ft./rev.

Since the desired readout is in feet, and there are

24 pulses per foot, it is necessary to scale the count.

To determine the multiplier that is needed, the

formula below is used.

K

T

= Desired Display Units = 1

¸ 24 = 0.041667

Number of Pulses

The remaining scale factor (K

R

) required is

determined by dividing the total scaling factor (K

T

)

by the number of count edges. (NCE).

K

R

= K

T

¸ NCE = 0.0416667 ¸ 1 = 0.0416667

The general rule for choosing a count scale

multiplier (SCM) is used to get the maximum

amount of decimal point accuracy. A Count Scale

Multiplier of 0.01 is used, which would give a scale

factor (rounded off) of 4.1667.

SF = K

R

¸ SCM = 0.0416667 ¸ 0.01 = 4.1667

If we used the count multiplier as the scale

factor, and used a scale multiplier of 1, the scale

factor would round off to 0.0417, in which case 2

decimal places of accuracy would be lost.