Sandvik Coromant Parting and grooving - users guide User Manual

Page 68

66

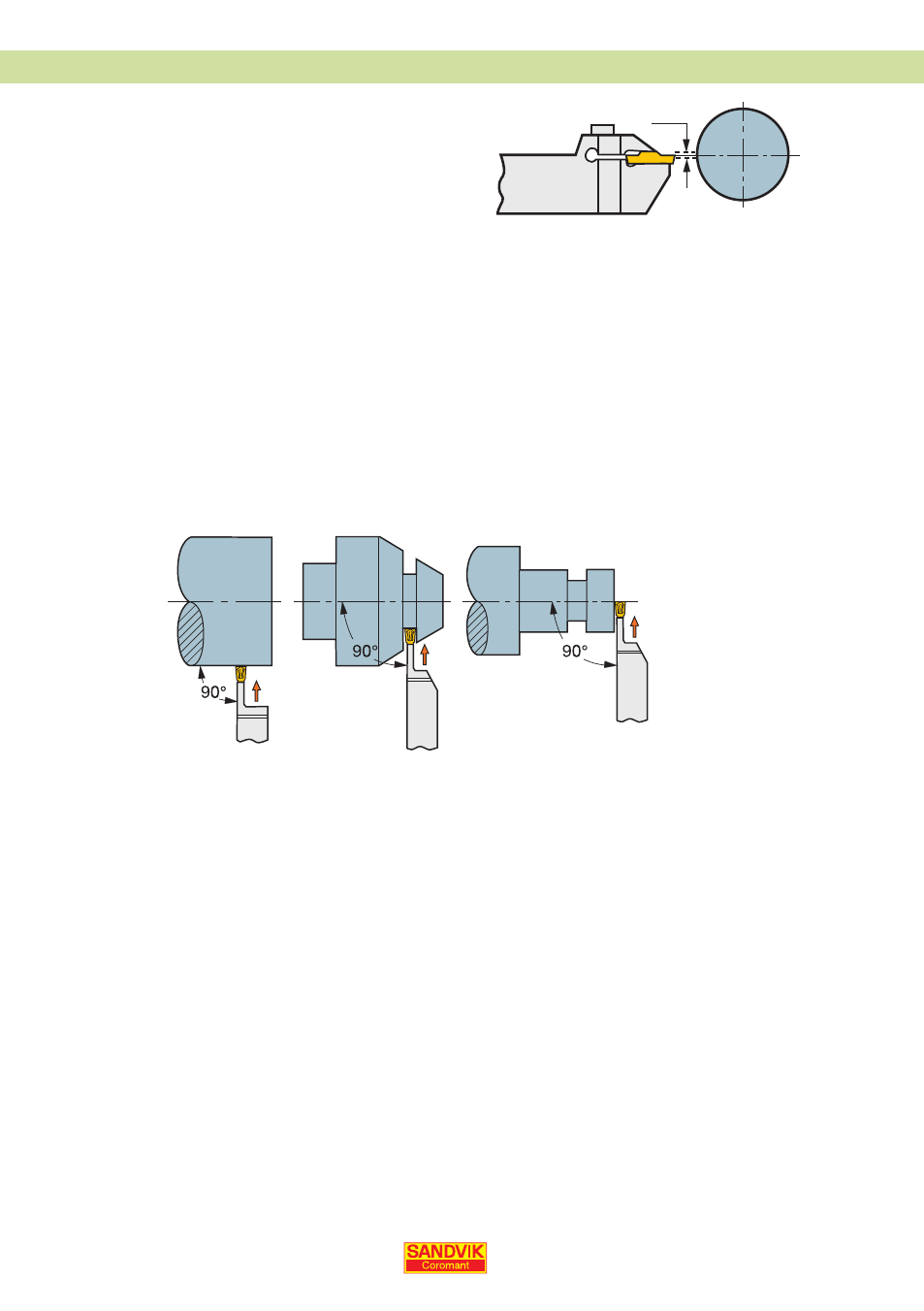

90° mounting

•

It is very important that the insert is mounted at 90° to the centre line of the workpiece

in order to obtain perpendicular surfaces without scratch marks and to reduce the risk of

vibration.

Cutting fluid

•

A large supply of cutting fluid, directed exactly on the cutting edge or under the edge,

should be used while the insert is engaged and throughout the operation.

Inserts mounted at 90° to the

centre line of work piece.

±0.1 mm

Correct centre height settings

•

It is essential when parting bars and

grooving relatively small diameters, that

the centre height setting is maintained to

a tolerance of ±0.1 mm. This has a major

influence on tool life, cutting forces and

pip size.

Practical hints