Practical hints, Case story, Pre-made grooved component – Sandvik Coromant Parting and grooving - users guide User Manual

Page 47

45

r

e

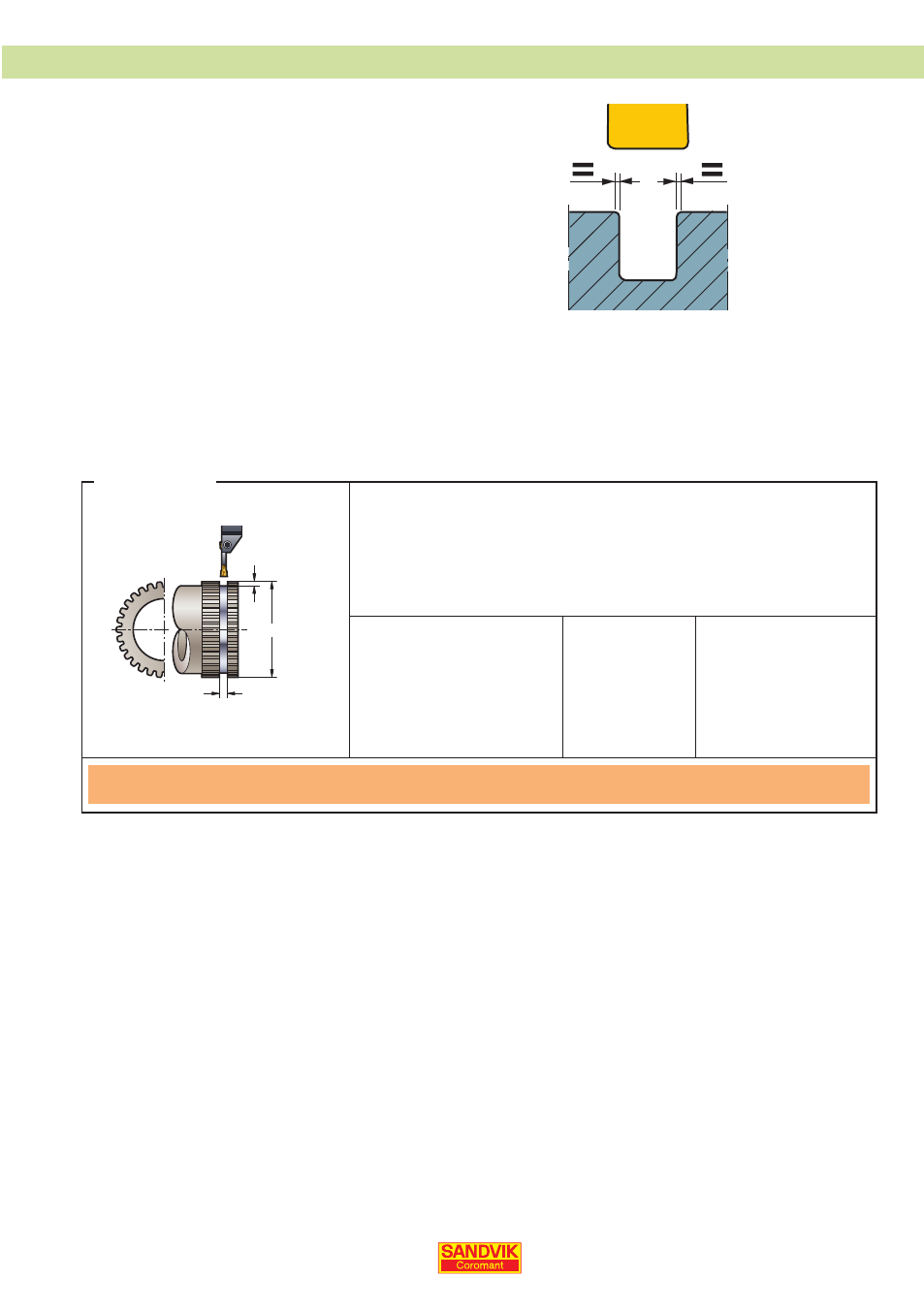

Adjust centre height to correct position to

•

get predictable tool life, see page 21.

When machining pre-made grooves adjust

•

horizontal position to equalize loads on

the corners in order to get long tool life. If

you have to machine in the bottom of the

groove, reduce feed at the end of the cut.

100

8 +0.1

3

Pre-made grooved component.

≤ 0.5 r

e

to reduce

notch wear

Practical hints

Machining specification

Operation: Grooving in hardened material

Material: 20 Mn Cr 5, CMC 04.1, 59–61 HRC

Machine: CNC turning lathe

Toolholder: LF123L25-3225BM

Insert: N123L1-080008S01025

Grade: CB7015

Cutting data

Insert width:

Cutting speed:

Radial/axial feed:

Time in cut:

Components:

Competitor

5 mm – 2 steps

170 m/min

0.04 mm/r

0.28 min

120 pcs/edge

Sandvik Coromant

8 mm – 1 steps

150 m/min

0.05 mm/r

0.13 min

169 pcs/edge

Case story

Tool life +44%

Productivity +115%

Annual time saving 112 hours