Grooving – Sandvik Coromant Parting and grooving - users guide User Manual

Page 29

27

Grooving

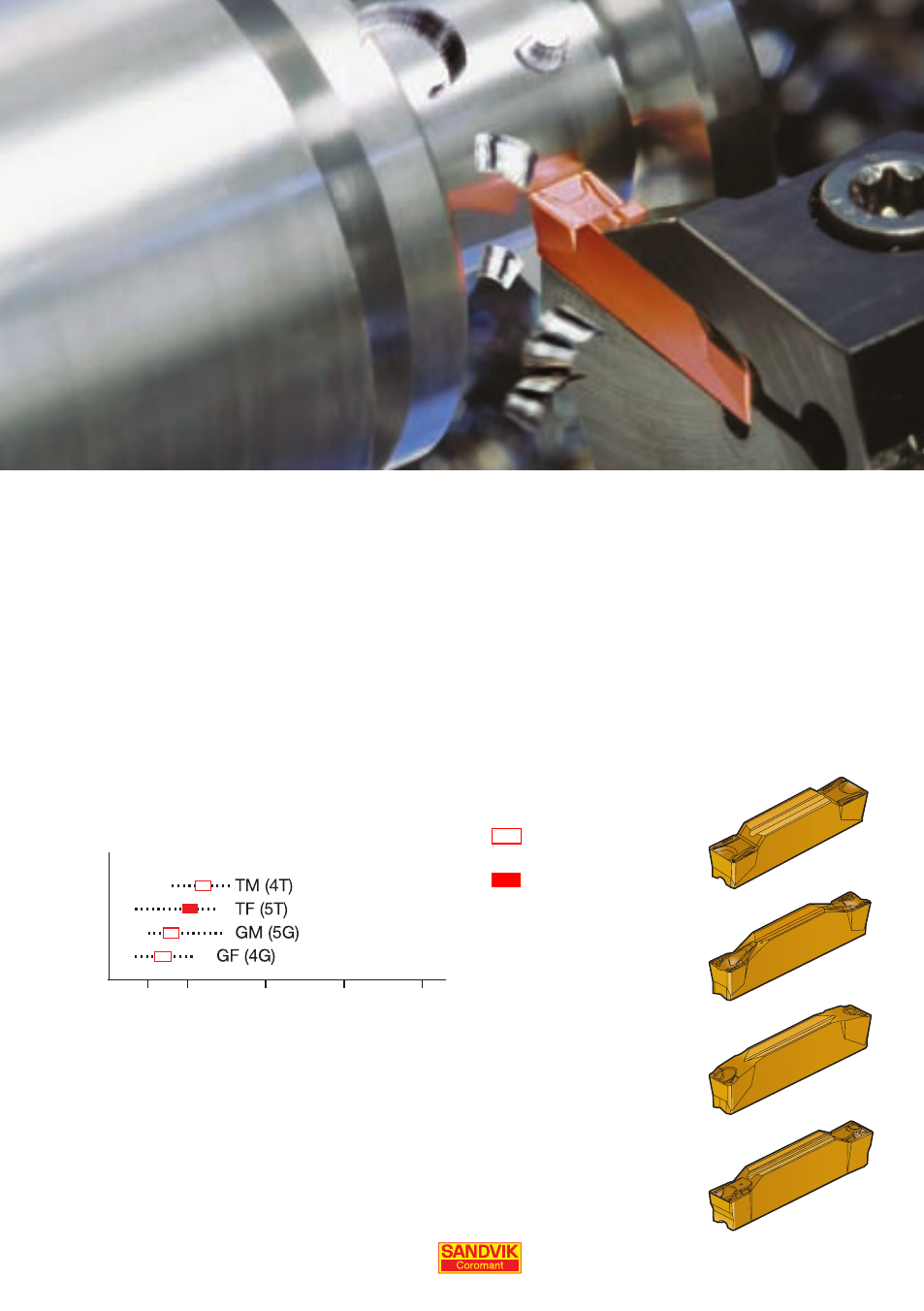

For grooving applications we offer dedicated geometries with the CoroCut system, e. g. GF,

GM, TF and TM. These geometries are designed to give specific benefits in both radial and

face grooving, and other machining methods such as external and internal multiple grooving

and plunge turning.

The different geometries are suitable for high or low feed machining.

For circlip grooving, U-Lock 154.0 is the first choice for productive solutions.

TF – First choice, all-round geometry.

TM – Productive side turning.

GM – Chip control in different material.

GF – Precision grooving.

For more information about cutting speed, see page 74.

Radial feed

Insert width (Ia),

3.0 m

Feed (f

n

),

mm/r

0,05 0,1

0,2

0,3

0,4

= Recommended

starting value.

= First choice.

TF

TM

GM

GF