Recommended grade and cutting data, Case story – Sandvik Coromant Parting and grooving - users guide User Manual

Page 36

34

Recommended grade and cutting data

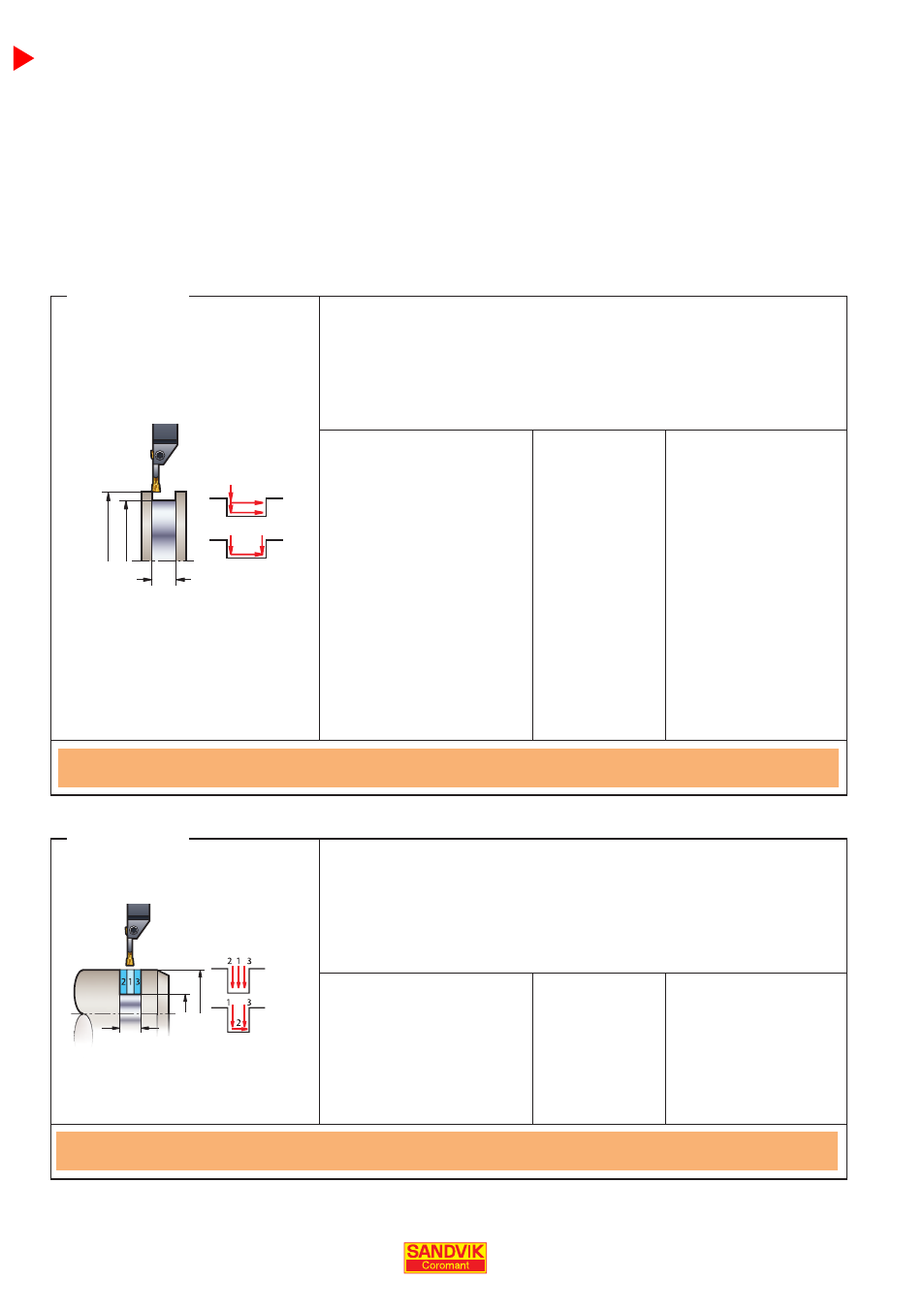

First choice geometry for turning of grooves is TF for low feed and TM for higher feeds.

Starting grade is GC1125. Cutting speed 150 m/min, radial feed 0.12 mm/r and axial feed

0.2 mm/r.

Roughing

Finishing

Ш 98

Ш 90

12.4

Roughing

Finishing

100

58

16

Tool life +15%

Productivity +68%

Annual time saving 91 hours

Tool life +23%

Productivity +7%

Annual time saving 63 hours

Machining specification

Operation: Plunge turning

Material: CMC 02.1

Machine: CNC turning lathe

Toolholder: LF123H13-2525BM

Insert: N123H2-0400-0004

Grade: GC1125

Cutting data - Roughing

Geometry:

Cutting speed:

Radial/axial feed:

Depth of cut:

Time in cut:

Components:

Cutting data - Roughing

Geometry:

Cutting speed:

Radial/axial feed:

Depth of cut:

Time in cut:

Components:

Total time in cut:

Competitor

220 m/min

0.15/0.2 mm/r

1.9 mm

0.23 min

350 pcs

Competitor

350 m/min

0.1 mm/r

0.25 mm

0.20 min

150 pcs

0.43 min

Sandvik Coromant

TM

250 m/min

0.15/0.2 mm/r

1.9 mm

0.20 min

400 pcs

Sandvik Coromant

TF

350 m/min

0.1 mm/r

0.25 mm

0.20 min

250 pcs

0.40 mn

Case story

Machining specification

Operation: Grooving

Material: Stainless steel, CMC 05.2

Machine: CNC turning lathe

Toolholder: LF123K32-2525BM

Insert: N123K2-0600-0004-TF

Grade: GC1125

Cutting data

Cutting speed:

Radial/axial feed:

Time in cut:

Components:

Competitor

120 m/min

0.15/0.2 mm/r

0.50 min

156 pcs

Sandvik Coromant

150 m/min

0.2/0.3 mm/r

0.298 min

183 pcs

Case story