Recommended grade and cutting data, Practical hints, Case story – Sandvik Coromant Parting and grooving - users guide User Manual

Page 43

41

Recommended grade and cutting data

Starting grade GC1125.

Cutting speed 125 m/min and feed 0.07 mm/r.

3.15

Ø 40

3

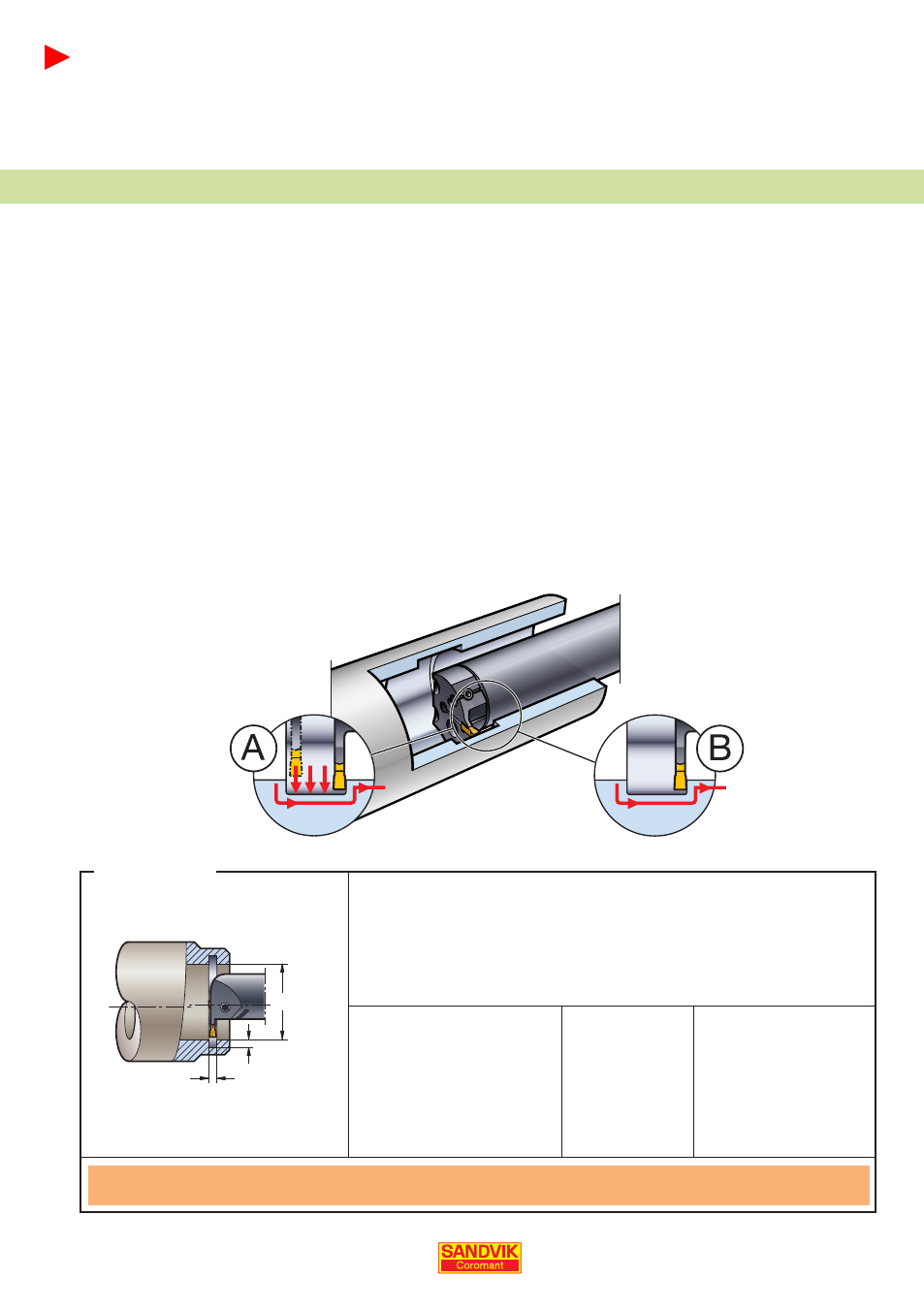

To avoid vibration the set up should have the shortest possible overhang with the lightest

cutting geometry possible e. g. GF or TF.

Vibration can also be avoided when machining large width grooves by making several inser-

tions with a narrower insert and then make a finishing cut, see illustration A.

A groove can also be machined with single insertion followed by plunge turning, see illustra-

tion B. This method also avoids vibration.

To get the best chip evacuation:

Start at bottom of the hole and machine back front of the hole.

•

Plunge turning/ramping.

•

Use right hand or left hand style inserts to direct chips when roughing.

•

Practical hints

Machining specification

Operation: Internal circlip grooving

Material: Stainless steel 316L, CMC 05.2

Machine: CNC turning lathe

Toolholder: RAG123G09-32B

Insert: N123G2-0315-0002-GF

Grade: GC1125

Cutting data

Cutting speed:

Feed:

Time in cut:

Components:

Competitor

110 m/min

0.06 mm/r

0.059 min

712 pcs/edge

Sandvik Coromant

140 m/min

0.1 mm/r

0.028 min

1230 pcs/edge

Case story

Tool life +73%

Productivity +100%

Annual time saving 60 hours