Parting of bars, Recommended grade and cutting data, Case story – Sandvik Coromant Parting and grooving - users guide User Manual

Page 22

20

Machining specification

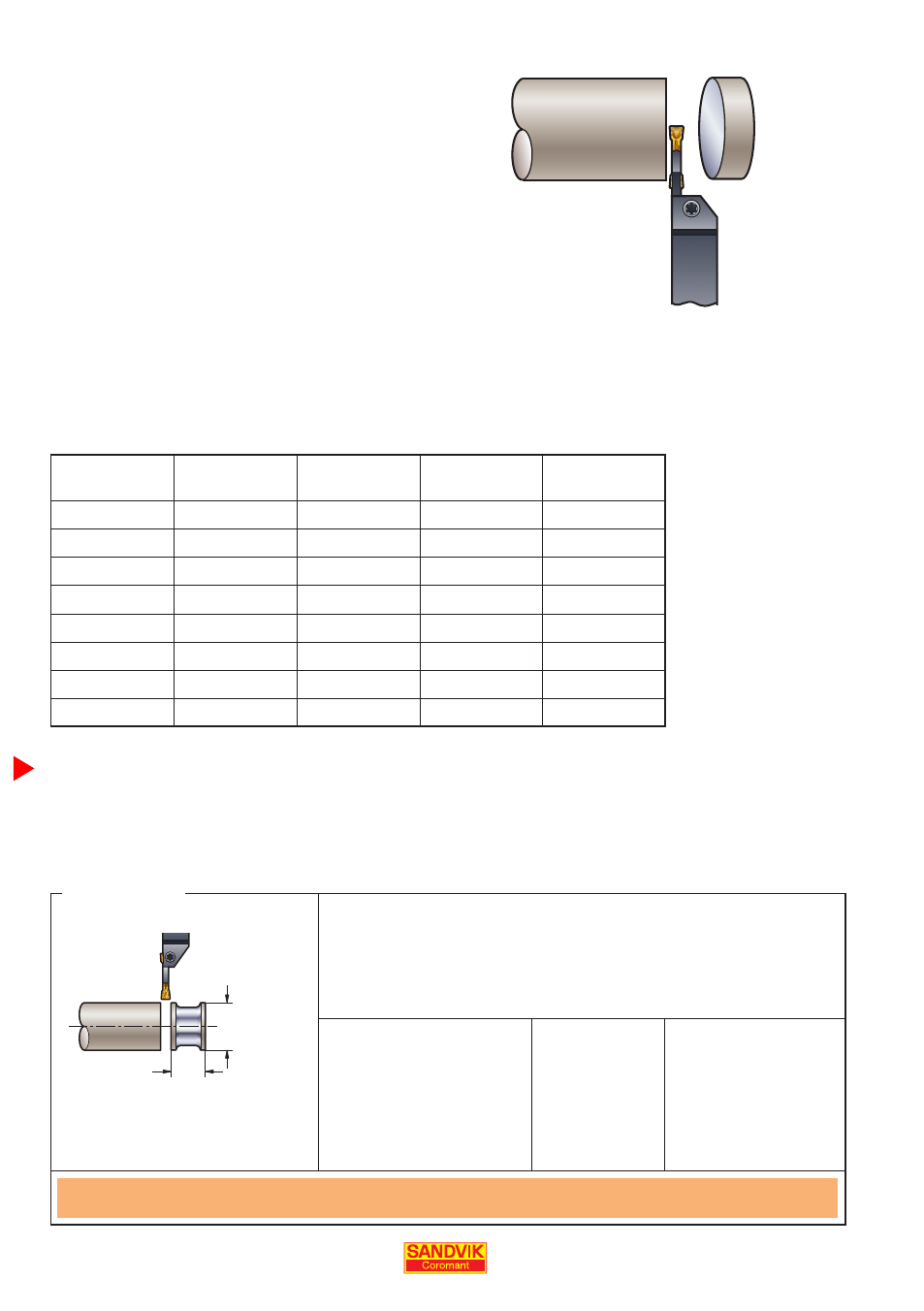

Operation: Parting off to centre

Material: JIS SCM 415, CMC 02.1, HB 240

Toolholder: LF123F10-2525B

Insert: N123F2-0250-003-CR

Grade: GC1125

Cutting data

Width of insert:

Cutting speed:

Feed (reduced at the end):

Time in cut:

Components:

Competitor

2.0 mm

129 m/min

0.05 mm/r

0.11 min

1200 pcs

Sandvik Coromant

2.0 mm

129 m/min

0.07 mm/r

0.08 min

2600 pcs

Parting of bars

When parting it is recommended to use an

insert as narrow as possible in order to save

material and minimise cutting forces.

Long overhangs (a

r

) causing instability could

result in tool failure and poor component

quality.

The recommended overhang should not

exceed 8 x la (width of insert).

Select correct width, geometry and system for parting of bars

Tool life +116%

Productivity +40%

Annual time saving 175 hours

Recommended grade and cutting data

Starting grade is GC2135. Cutting speed 125 m/min.

For more information about grades, see page 71.

Ø 20.5

15

Case story

Component

dia, mm

Insert width,

I

a

, mm

Insert

geometry

Tool system

Feed start

value, mm/r

< 8

1

CM/CS

CoroCut3

0.05

8–12

1.5

CM

CoroCut 2&3

0.07

12–16

2

CM

CoroCut 2

0.08

16–24

2.5

CR

CoroCut 2

0.08

24–32

3

CR

CoroCut 2

0.12

32–40

4

CR

CoroCut 2

0.15

40–48

5

4E

Q-Cut

0.18

48–56

6

4E

Q-Cut

0.20