Case story practical hints – Sandvik Coromant Parting and grooving - users guide User Manual

Page 31

29

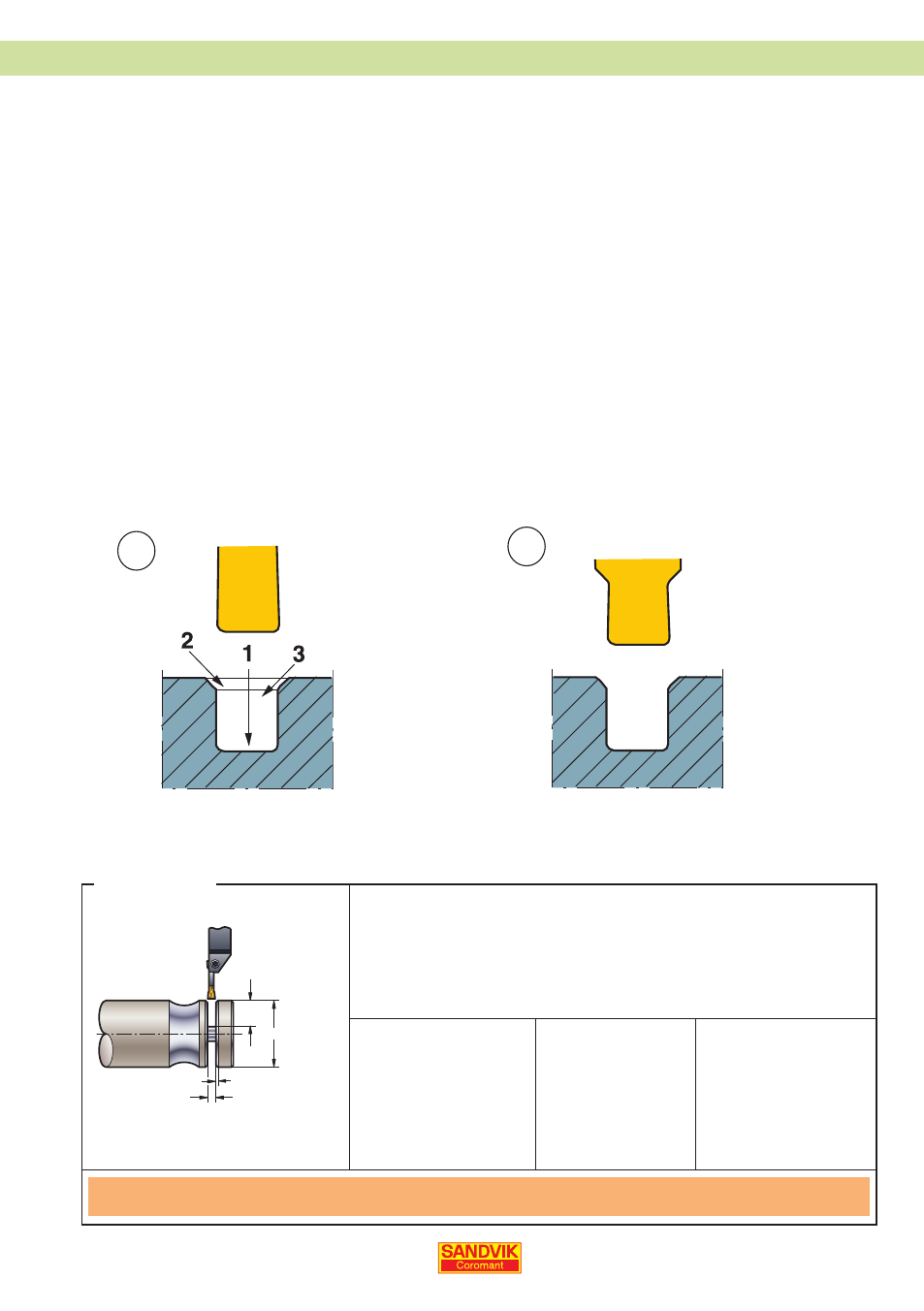

A

B

4

Ø 31.85

0.5 x 45º

11.3

When producing high quality grooves there is often a need for chamfered corners. One way

to produce these is to use a standard width CoroCut GF insert and after the groove is made,

use the corners of the insert to chamfer, see illustration A.

A more productive way when machining large series is to order a Tailor Made insert with the

exact form of the groove, see illustration B. Often cutting time can be reduced by up to 50%

compared to the previous method. In this case shape option 16 is used.

Read more about Tailor Made on page 78.

Machining specification

Operation: Grooving

Material: CMC 02.1, HB 240

Machine: CNC turning lathe

Toolholder: LF123H13-2020B

Insert: N123H2-0400-0002-GF

Grade: GC1125

Cutting data

Cutting speed:

Radial/axial feed:

Time in cut:

Components:

Competitor

110 m/min

0.07/0,04 mm/r

0.06 min

500 pcs

Sandvik Coromant

120 m/min

0.10/0.07 mm/r

0.04 min

1199 pcs

Tool life +139%

Productivity +56%

Annual time saving 173 hours

Case story

Practical hints