Burr free parting, Case story – Sandvik Coromant Parting and grooving - users guide User Manual

Page 27

25

Burr free parting

To avoid or minimise burrs use right or left hand style ground inserts with smallest possible

front angle that gives an acceptable component.

Inserts with 5° front angle are available in CF, CM and CR geometries. Inserts with 10° and

15° front angle are available in CS geometry.

Note that a large front angle reduces burrs, but will not produce a straight cut and will give

poorer surface finish and shorter tool life.

For straighter parting and the best stability use a screw clamp holder with the shortest over-

hang, a

r

. A reinforced toolholder will increase the stability even more.

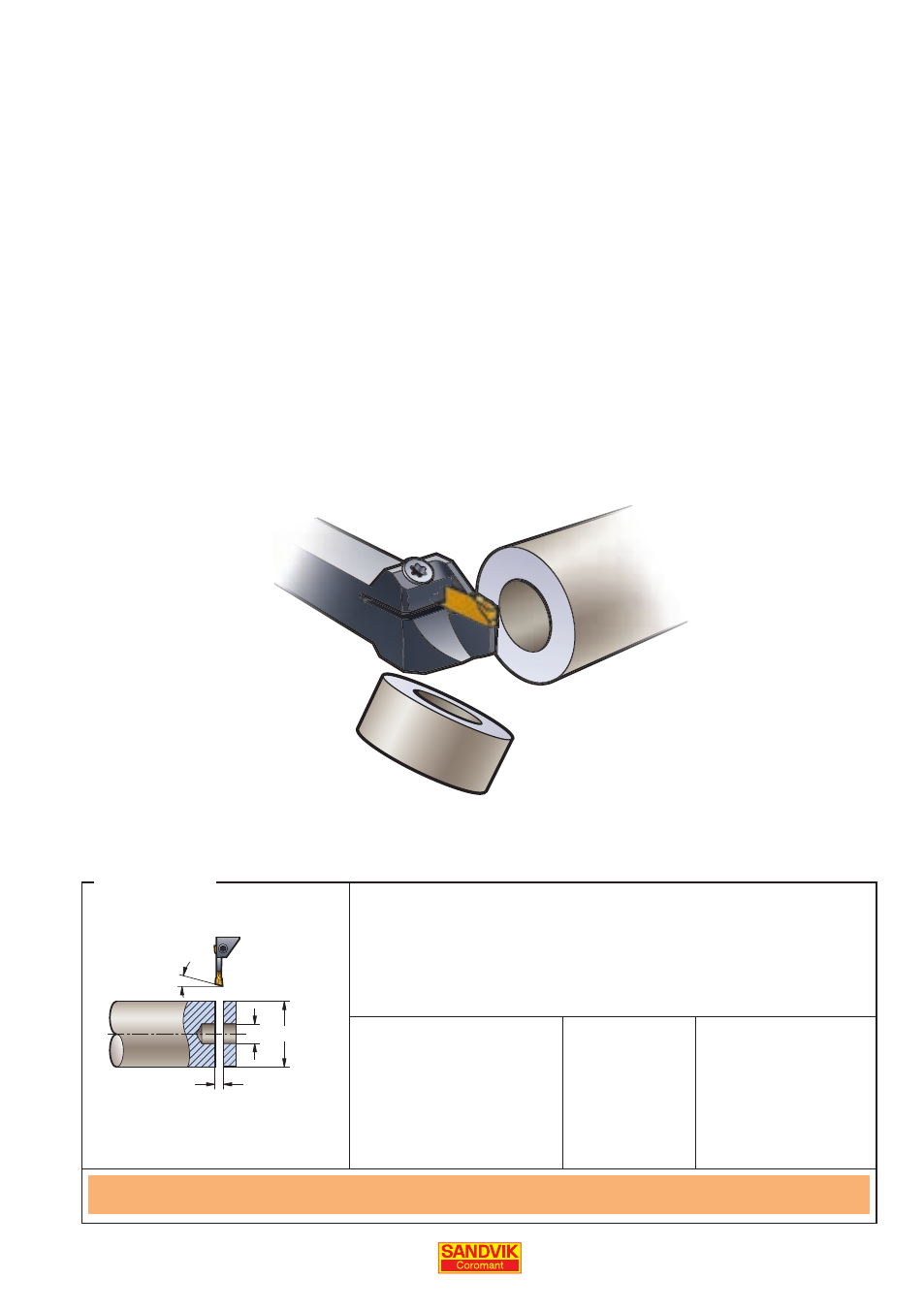

Parting with short overhang

and reinforced holder.

2.5

Ш 10 Ш 32

15º

Machining specification

Operation: Parting of a tube (burr free parting)

Material: CMC 01.1, HB 180

Machine: CNC turning lathe

Toolholder: LF123F20-2020B

Insert: L123F20-0250-1501-CS

Grade: GC1125

Cutting data

Cutting speed:

Feed:

Time in cut:

Components:

Competitor

150 m/min

0.1 mm/r

0.067 min

1100 pcs

Sandvik Coromant

150 m/min

0.1 mm/r

0.067 min

2000 pcs

Tool life +82%

Productivity +4%

Annual time saving 8 hours

Case story