Finishing of grooves, Cycle time comparison, Plunge turning – Sandvik Coromant Parting and grooving - users guide User Manual

Page 34: Multiple grooving

32

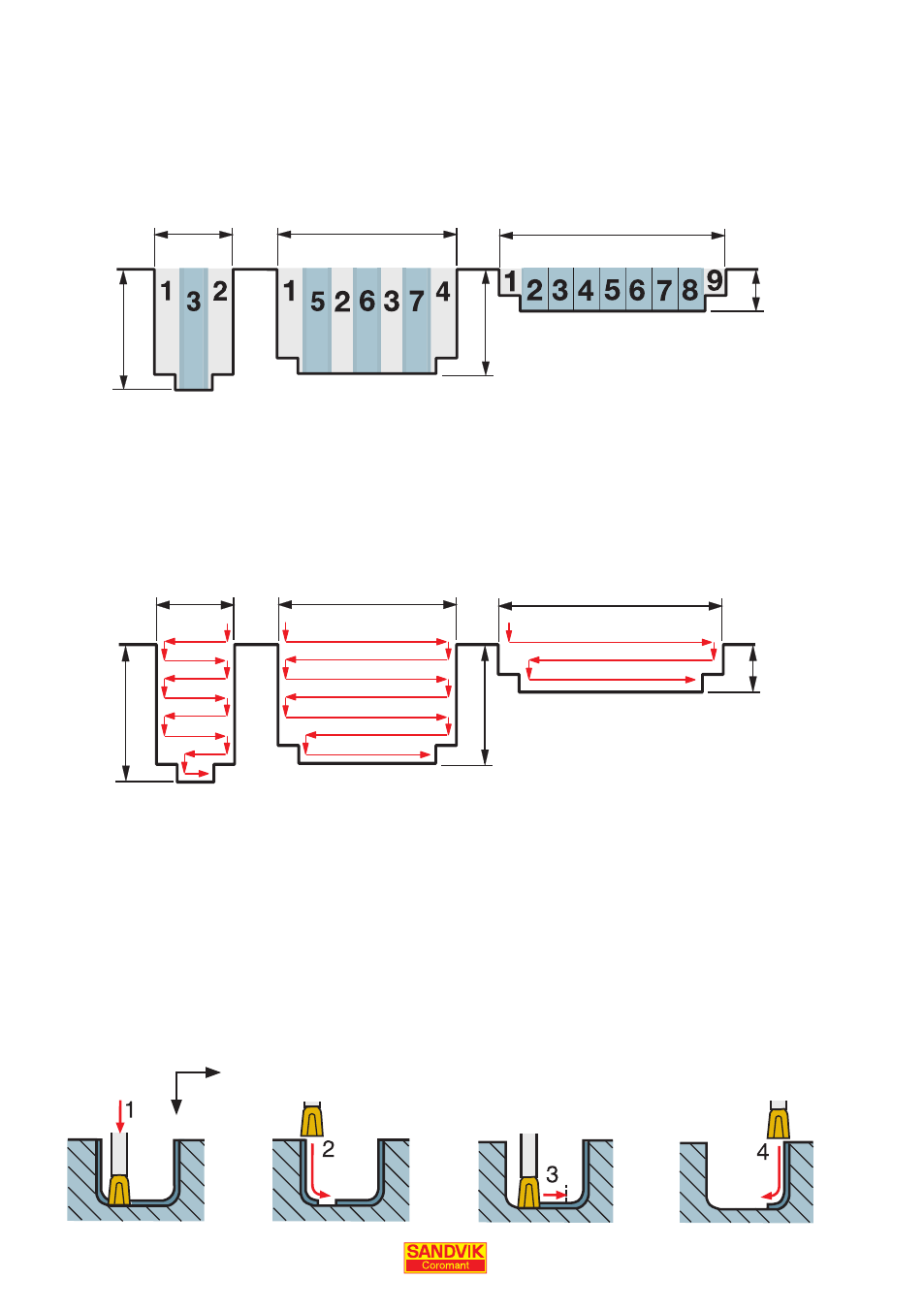

Finishing of grooves

Care must be taken when machining around the bottom radius of the groove. As the insert

contours around the radius, most of the movement is in the Z direction. This produces an

extremely thin chip along the front cutting edge and can result in rubbing and hence vibra-

tion.

To prevent this adopt the following machining sequence – axial and radial cutting depth

should be 0.5–1.0 mm.

Plunge turning

Direction of feed

Feed – axial – 0.3 mm/r

Direction of feed

Feed – radial – 0.2 mm/r

Cycle time comparison

Insert width 6 mm

Insert width 6 mm

Depth of cut 3 mm

Direction of feed

Feed 0.2 mm/r

24

16

36

46

21

9

Multiple grooving

24

16

36

46

21

9

x

z

32 sec

70 sec

56 sec

37 sec

68 sec

(7 passes)

44 sec

(3 passes)