Case story – Sandvik Coromant Parting and grooving - users guide User Manual

Page 40

38

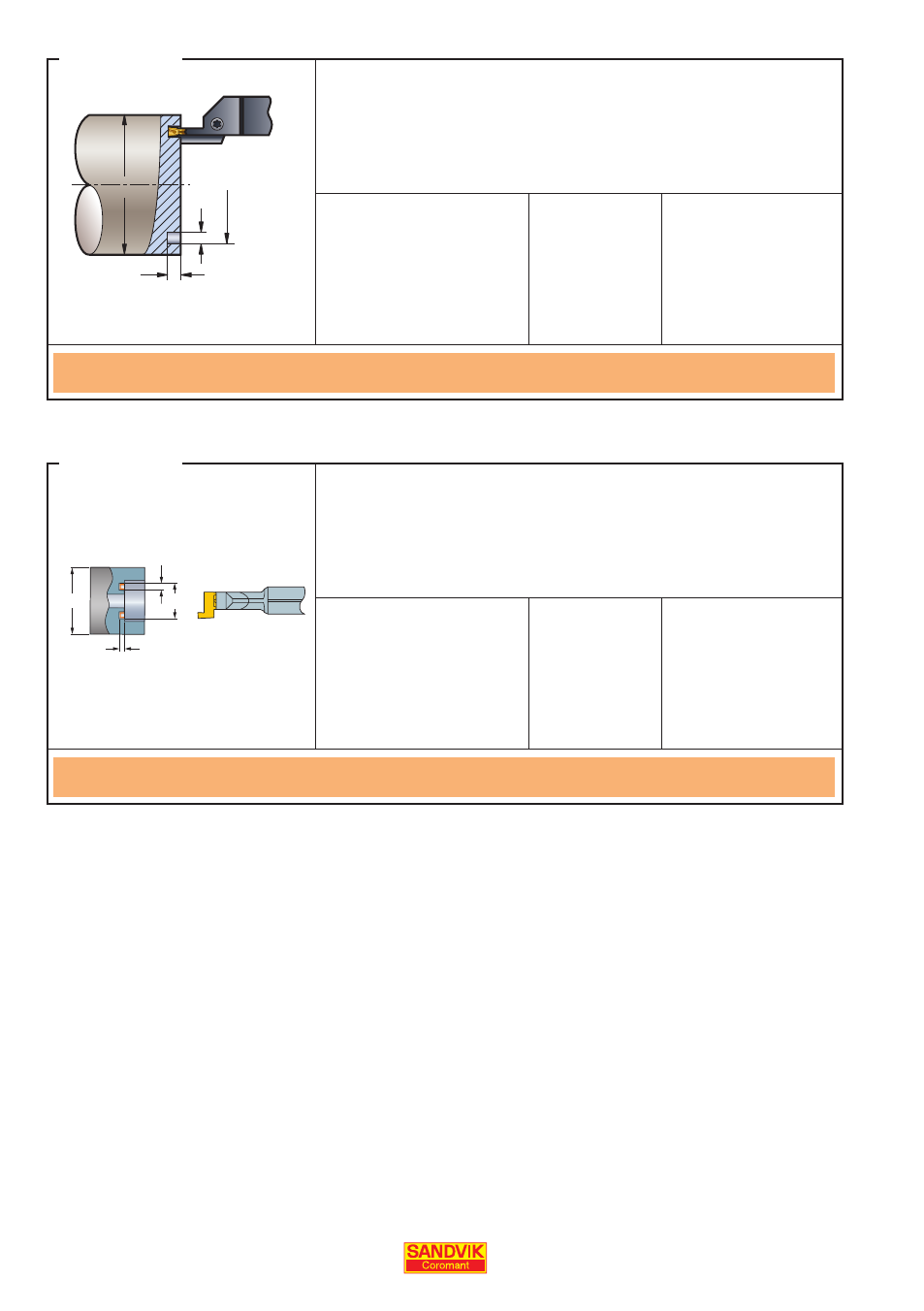

ш25

2,8

2,0

ш17

7

Ш 70

6

Ш 90

Machining specification

Operation: Face grooving

Material: Stainless steel SS 2343, CMC 05.2

Machine: CNC turning lathe

Toolholder: RF123K25-2525B-058BM

Insert: N123K2-0600-0004-TF

Grade: GC2135

Cutting data

Cutting speed:

Feed:

Time in cut:

Components:

Competitor

110 m/min

0.08 mm/r

0.18 min

390 pcs/edge

Sandvik Coromant

110 m/min

0.16 mm/r

0.09 min

560 pcs/edge

Tool life +100%

Productivity +44%

Annual time saving 43 hours

Case story

Machining specification

Operation: Face grooving

Material: Unalloyed steel, C35, CMC 01.1

Machine: CNC Bar feed

Toolholder: MB-A16-20-09R

Insert: MB-09AF200-02-14R

Grade: GC1025

Cutting data

Cutting speed:

Feed:

Time in cut:

Components:

Competitor

95 m/min

0.02 mm/r

0.17 min

400 pcs/edge

Sandvik Coromant

150 m/min

0.025 mm/r

0.09 min

500 pcs/edge

Tool life +25%

Productivity +95%

Annual time saving 284 hours

Case story