Practical hints – Sandvik Coromant Parting and grooving - users guide User Manual

Page 23

21

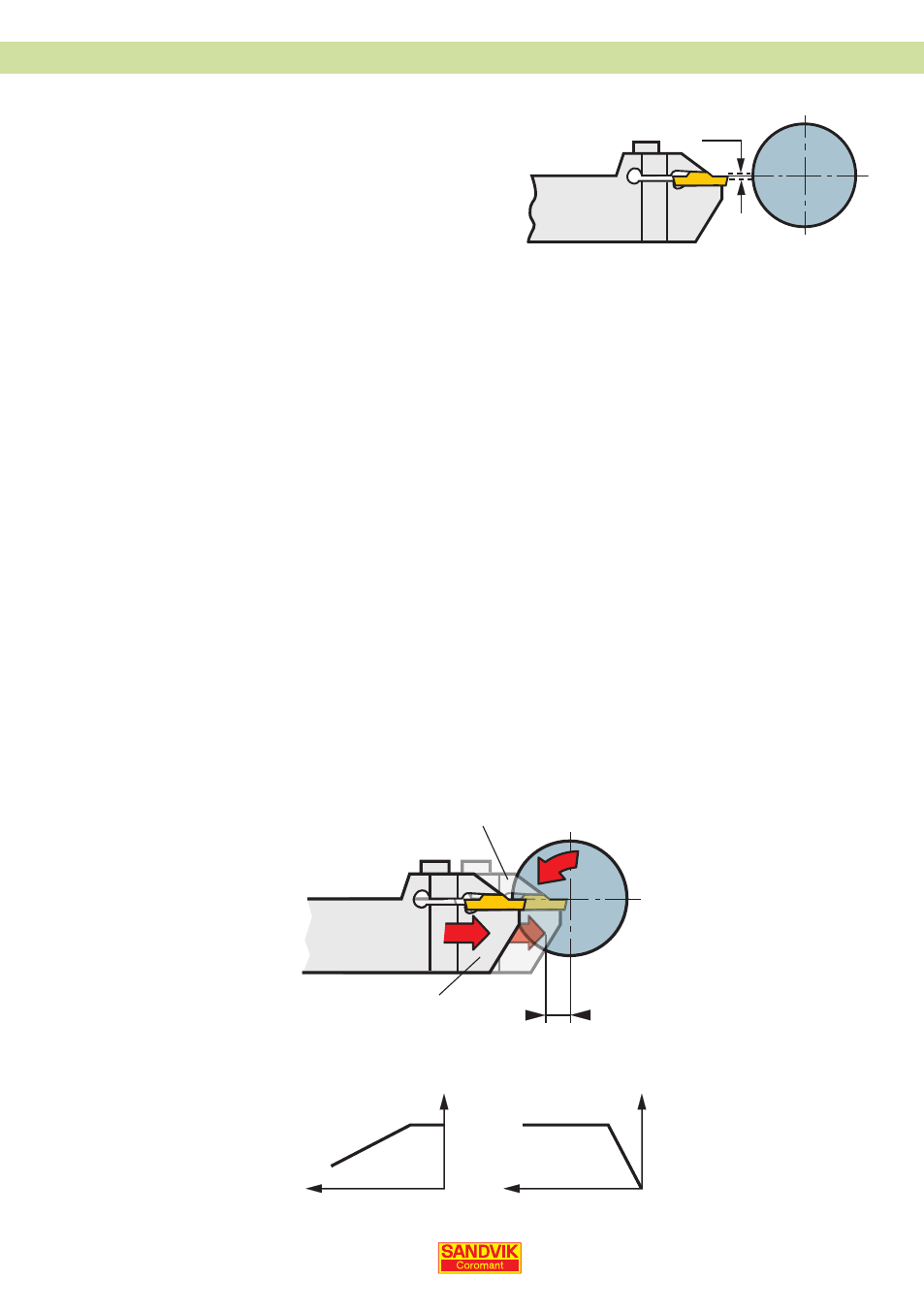

±0.1 mm

Practical hints

For a correct cutting process, be sure that

the cutting edge height is maintained at a

tolerance of ±0.1 mm of work piece centre.

The most difficult sequence in parting to

centre is when the component “drops” off.

The cutting speed is extremely low, generat-

ing built-up edge on the insert corner. When

the cut-off part of the component falls there

is a large risk of chipping of the insert cor-

ners.

To increase tool life substantially and prevent inconsistent performance:

Re

•

duce the feed rate by up to 75% – around 2 mm prior to the part falling off.

Stop the parting operation prior to reaching the centre point. The cut-off part will drop at

•

a point prior to centre due to its weight and length. Leave the pip on the bar to be faced

off with a conventional tool.

Do not pull insert back after cutting off, pull it away then back.

•

Dwelling (microsteps) helps chip breaking in long chipping materials.

•

When cutting hexagon bars, a reduction of feed is necessary until you have a constant cut-

•

ting.

Increase speed aas the bar gets shorter in bar feeding machines.

•

A subspindle can be used to pull away the component before the insert reaches the centre.

•

fn

n

D

D

vc

Feed rate reduction.

0.25 x fn

~2 mm