JKS 4100 User Manual

Page 3

JKS4100

JKS Quicker Disconnect Installation

Page 3

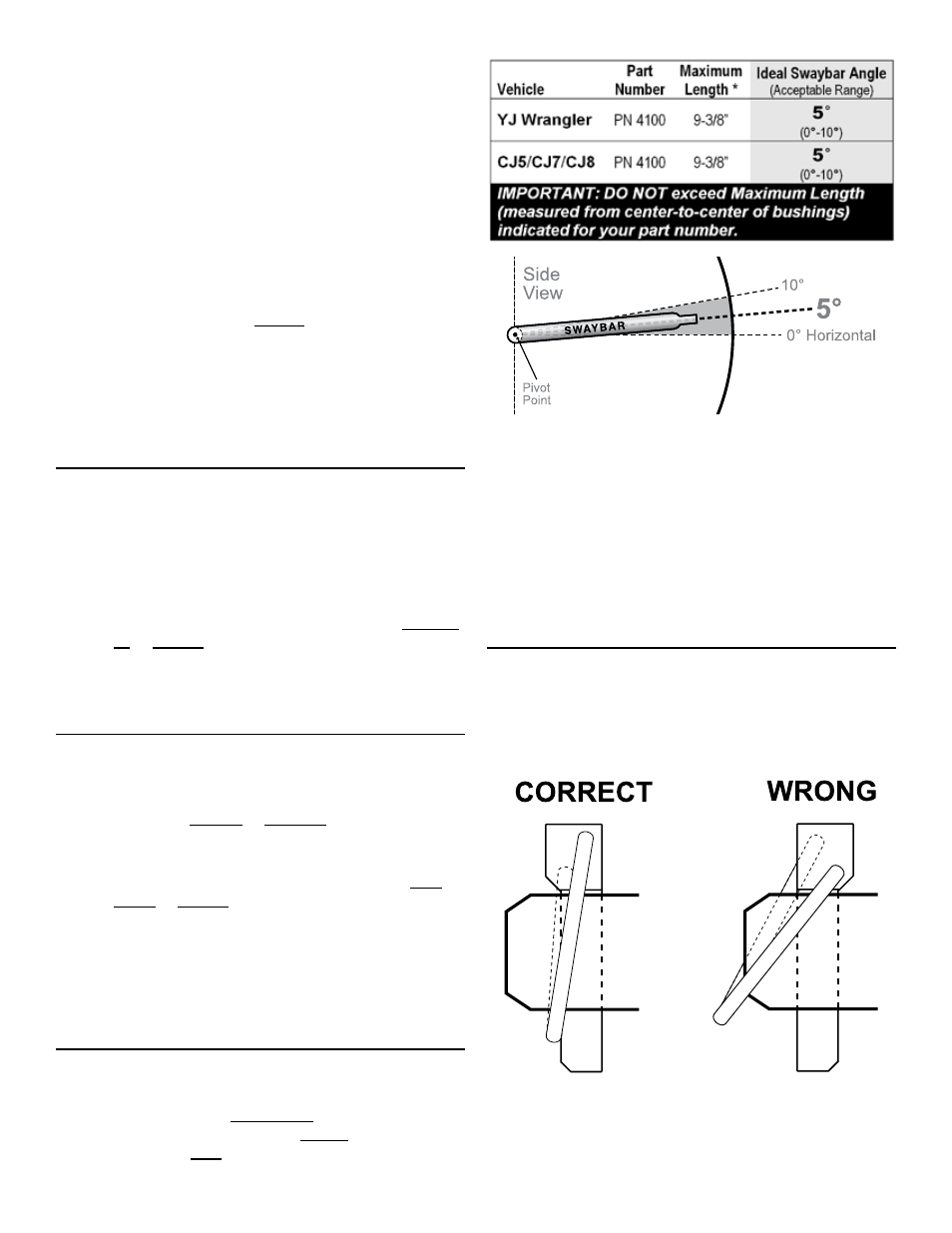

To determine the proper location for the lower

mounting tab, temporarily slide the Upper End (G)

of Quicker Disconnect onto the Upper Stainless

Steel Post (C) and adjust angle of swaybar to Ac-

ceptable Range (0°-10°).

HINT: Refer to Step 6 on

next page for illustration of swaybar angle.

Temporarily insert the threaded end of Lower

Stainless Steel Post (L) into Weld-on Tab (J) and

secure with 1/2” Nylock Nut (K). Slide tab and post

assembly into Lower End (H) of Quicker Discon-

nect.

Choose the configuration for the Lower Mount-

ing Tab that allows the Quicker Disconnect to be

installed as close to vertical as possible. Length

of Quicker Disconnect may be adjusted as long

as it does NOT exceed Maximum Length of 9-3/8”

(measured from bushing centers).

Mark the location on the axle tube where Weld-on

Tab (J) will be installed.

4. MOUNT WELD-ON TAB TO AXLE TUBE

Remove tab and post assembly from Lower End

(H) of Quicker Disconnect and disassemble.

Remove paint from axle tube where Weld-on Tab

(J) will be mounted and clean area thoroughly.

Weld lower mounting tab to axle tube so that

Stainless Steel Post – when installed – is horizon-

tal or parallel with the ground.

Paint Weld-on Tab (J) and any bare metal on axle

tube with spray paint to prevent corrosion.

5. INSTALL LOWER TAPERED POST

Re-insert threaded end of Lower Stainless Steel

Post (L) into Weld-on Tab (J). Tapered end of post

must point forward or outboard, depending on the

mounting configuration chosen.

Secure Stainless Steel Post (L) with 1/2” Nylock

Nut (K), ensuring small Click Pin holes are hori-

zontal or parallel with ground.

Tighten 1/2” Nylock Nut (K) to 65 ft-lb. using a

torque wrench.

HINT: A small Philips head screw-

driver or punch inserted into the Click Pin hole

will enable you to prevent the Stainless Steel Post

from rotating when tightening the mounting bolt.

6. SET QUICKER DISCONNECT LENGTH

Adjust the length of your Quicker Disconnects until

swaybar is at the Ideal Angle or within Acceptable

Range. Vehicle must be at normal ride height and

located on level ground.

IMPORTANT: DO NOT exceed Maximum Length (mea-

sured from center-to-center of bushings) indicated for

your part number.

Once adjusted, lay Quicker Disconnects on a flat

surface and tighten Jam Nuts (M) firmly against

the Lower Ends (H).

IMPORTANT: Bushing cradles at both ends of Quicker

Disconnect must remain parallel with their respective

mounting posts when Jam Nut is tightened.

7. INSTALL QUICKER DISCONNECTS

Slide Upper End (G) of Quicker Disconnect onto

the Upper Stainless Steel Post (C) and Lower End

(H) onto Lower Stainless Steel Post (L).

Insert Click Pins (D) as illustrated to secure.

IMPORTANT: When properly installed, the ring on the

Click Pin will “snap” against the shaft of pin. When in-

stalled backwards, the ring does not fit snugly against

shaft.