NORD Drivesystems BU0080 User Manual

Page 22

NORDAC DeviceNet Manual

22

BU

0080

GB

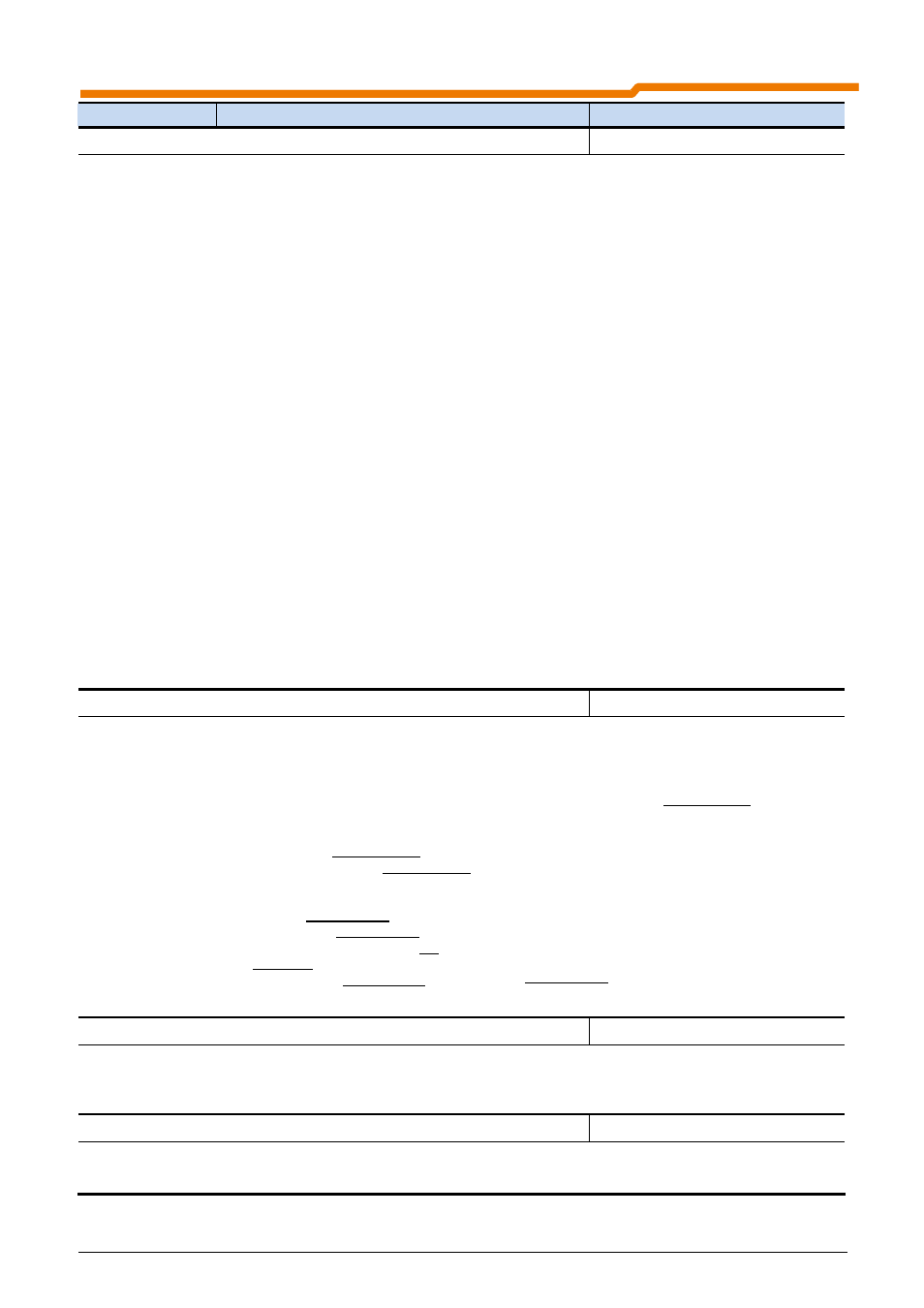

Parameter

Setting value / Description / Note

Comments

P546 (P)

Bus setpoint 1

In this parameter, a function is assigned to the delivered setpoint 1 (SW1) for bus control.

NOTE: Further details can be found in the respective FI manual or in the description of P400.

0 ... 7 (47)

[ 1 ]

SK 300E, SK 700E SK 750E

0 = Off

1 = Setpoint frequency (16 bit)

2 = 16 Bit setpoint position (only

posicon, SK700/750E)

3 = 32 Bit setpoint position (only

posicon, SK700/750E and if

PPO- type 2 or 4 are

selected)

4 = Control terminals posicon

(only posicon, SK700/750E,

16Bit)

5 = Setpoint position (16 Bit)

increment

1

(onlyposicon,

SK700/750E)

6 = Setpoint position (32 Bit)

increment

1

(onlyposicon,

SK700/750E)

7 = Bus IO In Bits 0-7

SK 500E

0 = Off

1 = Setpoint frequency (16 bit)

2 = Torque current limit (P112)

3 = Actual frequency PID

4 = Frequency addition

5 = Frequency subtraction

6 = Current limit (P536)

7 = Maximum frequency (P105)

8 = Actual PID frequency limited

9 = Actual PID frequency monitored

10 = Torque servo mode (P300)

11 = Lead torque (P214)

12 = Reserved

13 = Multiplication

14 = PI process controller actual value

15 = PI process controller setpoint

16 = PI process controller lead

17 = Digital In bits 0...7

18 = Reserved

19 = Set relay (P434/441/450/455=38)

20 = Set analog output (P418=31)

21 = Setpoint position Low word (SK 530E and above)

22 = Setpoint position High word (SK 530E and above)

23 = Setpoint position increment Low word (SK 530E and above)

24 = Setpoint position increment High word (SK 530E and above)

25 = ... 45 Reserved

46 = Setpoint torque process controller

47 = Gearing transfer factor

P547 (P)

Bus setpoint 2

In this parameter, a function is assigned to the delivered setpoint 2 (SW2) for bus control.

0 ... 46 (47)

[ 0 ]

0 = Off

1 = Setpoint frequency

2 = Torque current limit (P112)

3 = Actual frequency PID

4 = Frequency addition

5 = Frequency subtraction

6 = Current limit (not SK 300E)

7 = Maximum frequency (not SK 300E)

8 = Actual PID frequency limited

9 = Actual PID frequency monitored

10 = Torque (not SK 300E)

11 = Torque lead (not SK 300E)

12 = Control terminals posicon (not

SK 300E)

13 = Multiplication (not SK 300E)

14 = PI process controller actual value

15 = PI process controller setpoint

16 = PI process controller lead

17 = Digital In bits 0...7

18 = Curve travel calculator (not SK 300E)

19 = Set relay

20 = Set analog output

21 = Setpoint position Low word (SK 530E and above)

22 = Setpoint position High word (SK 530E and above)

23 = Setpoint position increment Low word (SK 530E

and above)

24 = Setpoint position increment High word (SK 530E

and above)

25 = ... 45 Reserved

46 = Setpoint, torque process controller

(not SK 300E)

47 = Gearing transfer factor (only SK 500E)

P548 (P)

Bus setpoint 3

In this parameter, a function is assigned to the delivered setpoint 3 (SW3) for bus control. This is

only available if P546

≠

is 3 (only applies for SK 700E / SK 750E).

0 ... 46 (47)

[ 0 ]

For setting values, see parameter (P547)

P551 Drive

profile

always visible

0 ... 1 (On / Off)

[ 0 = Off ]

Depending on the option, this parameter is used to activate the CANopen profile DS401

or the InterBus Drivecom profile .