Easicool™eze precision air conditioning, Introduction – Airedale EasiCool 6kW 64kW User Manual

Page 14

EasiCool™EZE

Precision Air Conditioning

1

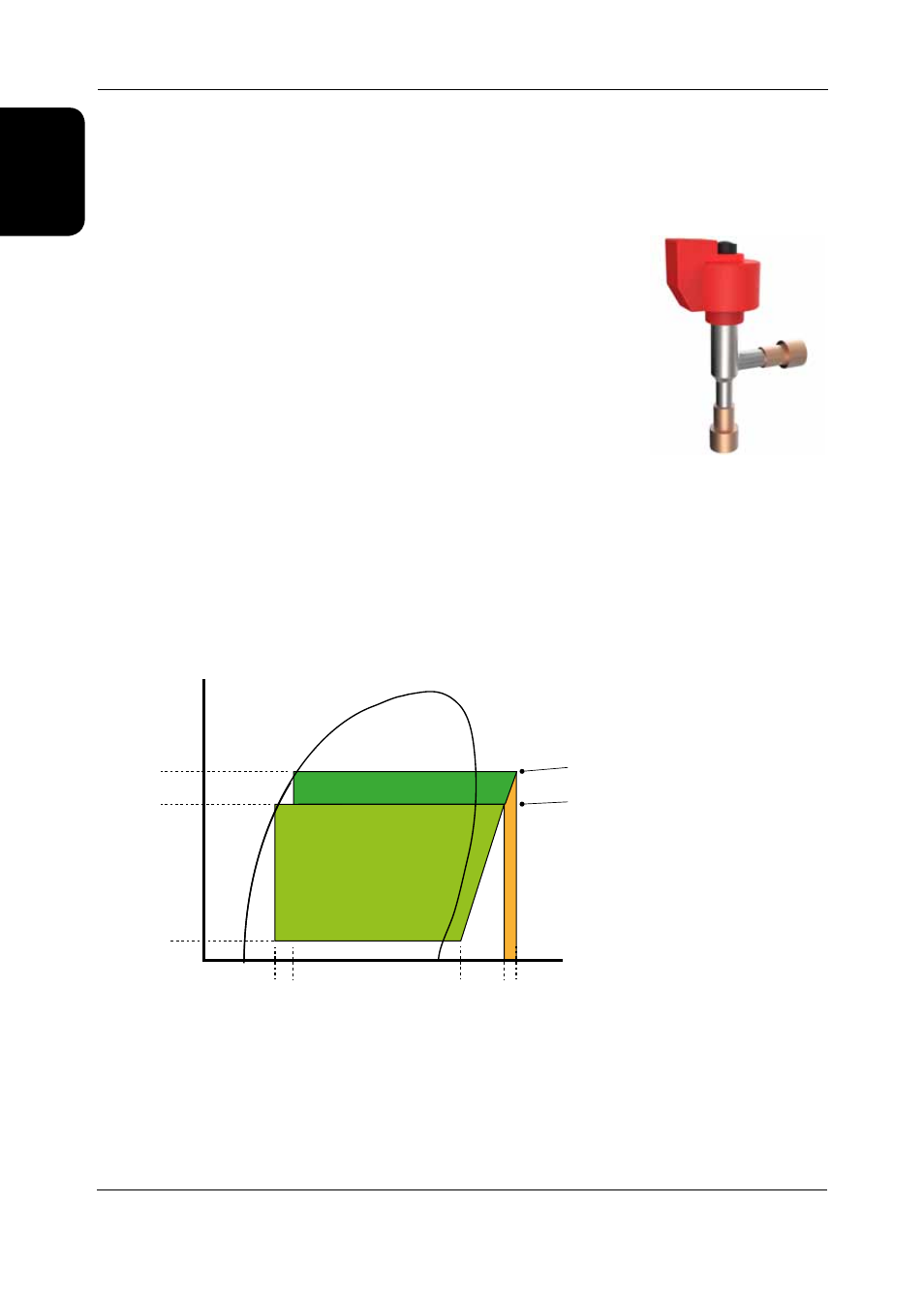

Compression

2

Condensation

3

Expansion

4

Evaporation

Key:

(1) Cooling Cycle @ 22°C ambient with a conventional TEV fitted.

(2) Cooling cycle @ 22°C ambient, demonstrating a typical EEV condensing temperature taking full advantage of lower

ambient air temperatures (below 35°C).

Electronic Expansion Valves (EEV)

Electronic expansion valves differ to the normal thermostatic expansion valves in their

ability to maintain control of the suction superheat at reduced head pressures. This

can lead to significant energy savings particularly at reduced loading and low ambient

temperatures.

EEV step position, superheat setpoint, head pressure set point and other features can be

viewed and adjusted via the microprocessor display.

Whilst offering versatile control at the full design duty of the unit, TEVs do not

automatically optimise themselves to all operating conditions. Therefore, if the refrigeration

system is operating at 40% or 50% of full load, especially at a lower ambient temperature

than that for which the valve was sized, the conventional TEV must have the design

head pressure available to ensure good refrigerant control. Maintaining an artificially high

condensing pressure is normal in conventional systems.

Using an EEV allows for good refrigeration control whilst operating at part load and lower

ambient conditions with a reduced condensing pressure. By fitting an EEV and adjusting

the head pressure control setting an increase in the system EER (Energy Efficiency Ratio)

of up to 30% can typically be seen. The Mollier diagram shown below helps to illustrate

how this increase in efficiency is achieved.

EEV’s differ to normal thermostatic expansion valves in their ability to maintain control

of refrigerant flow and the suction superheat at reduced head pressures. The turn-down

rate of a typical EEV is superior to that of it’s thermostatic equivalent, such that a reduced

optimum condensing pressure can be maintained at low compressor load. However low

the load is on the compressor, from zero to 100%, there will not be a problem with turn

down, even down to 10% of the valves rated capacity.

Heat of Rejection

Reduction in

Compressor Input

Power

Enthalpy kJ/kg

Increase in

Cooling Duty

Evaporating

Pressure

Reduced

Condensing

Pressure

Presssure

Bara

Thermostatic Expansion Valve (1)

Electronic Expansion Valve (2)

1

2

3

4

14

Introduction

EasiCool™ EZE Technical Manual 7588163 V1.1.0_02_2013