Operation – KROHNE H250 M40 EN User Manual

Page 41

OPERATION

6

41

H250 M40

www.krohne.com

11/2012 - 4000640702 MA H250 M40 R02 en

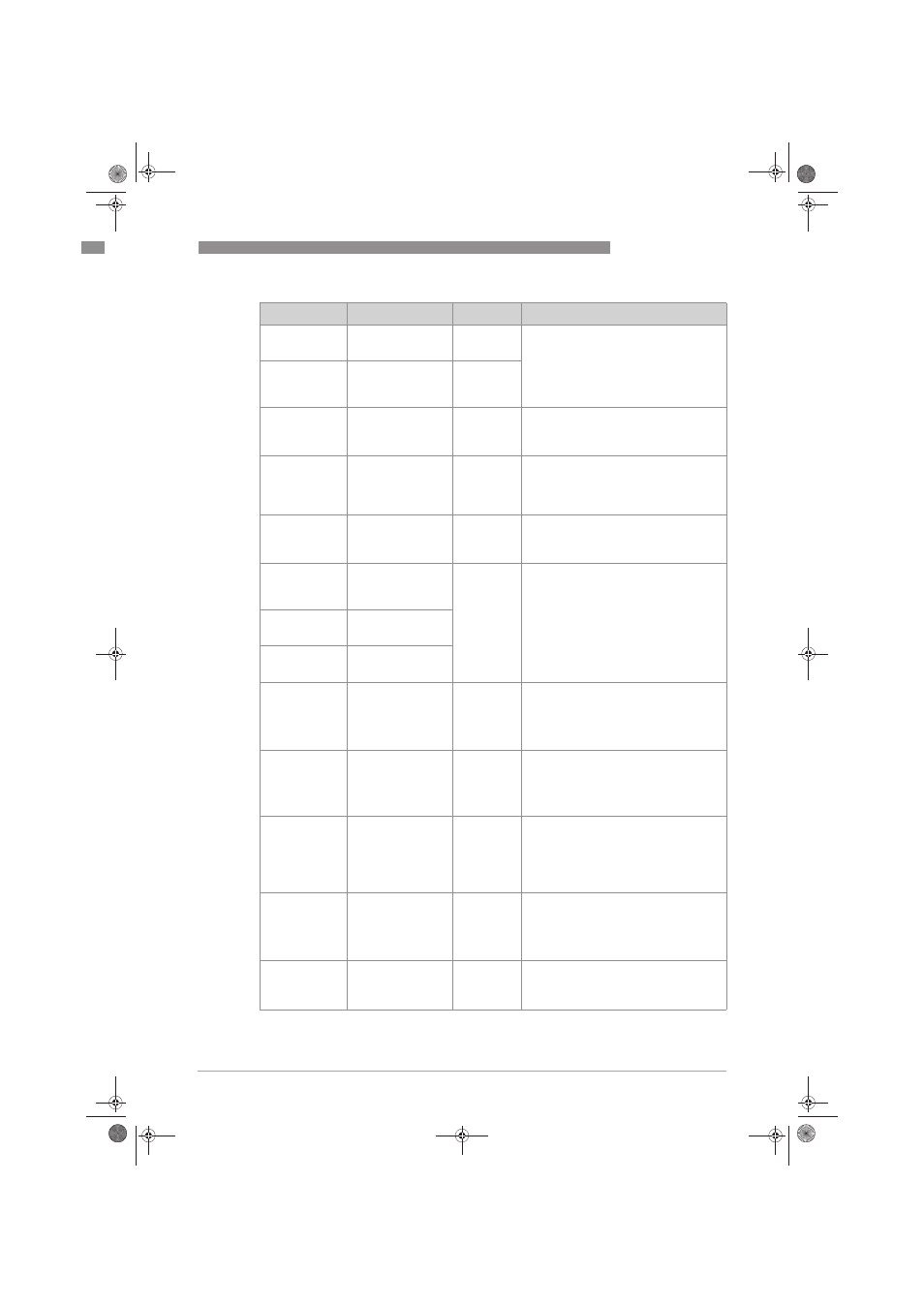

Error Message

Description

Category

Remedy

NOT LINEARIZED Linearization faulty or

not activated =

measuring error

Maintenance

Activate linearization or carry it out again

(HART

®

communication and linearization

software are required; the original

calibration values must be known), or send

the device back to the manufacturer for

linearization.

NEW LINEARI.

TABLE BAD

Faulty or missing

data in the

linearization table =

measuring error

Warning

LINEARIZATIO

UNDER CONFIG

The device is in

linearization mode =

measuring error

Warning

Complete the linearization and activate it

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

UNIT SYSTEM

CONFLICT

The unit for the

linearization flow is

incompatible with the

selected flow type

(mass/volume)

Warning

Correct error, carry out linearization again if

necessary (HART

®

communication and

linearization software are required), or send

the device back to the manufacturer for

linearization.

TOO FEW

ENTRIES

The linearization

table has too few data

points

Warning

Carry out linearization at at least 5 points

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

NOT

MONOTONOUS

The sequence of the

linearization values is

not strictly monotonic

increasing

Warning

Check linearization and/or carry it out again

(HART

®

communication and linearization

software are required), or send the device

back to the manufacturer for linearization.

FIRST NOT 0 %

The first flow value if

the linearization table

is not 0%

LAST NOT 100 %

The last flow value if

the linearization table

is not 100%

NO ZERO CAL

OF AO

The current output

zero point 4.00mA is

not calibrated. =

possible measuring

error in process

control.

Maintenance

Perform calibration using ammeter and

menu 3.10 or using standard HART

®

tools/process control system and poss.

external ammeter. Caution: during

calibration, switch the measuring point to

manual control.

NO F.SC. CAL

OF AO

The current output

100% = 20.00mA is

not calibrated. =

possible measuring

error in process

control.

Maintenance

Perform calibration using ammeter and

menu item 3.11 or using standard HART

®

tools and external ammeter if necessary.

Caution: during calibration, switch the

measuring point to manual control.

NO TEMP.

COMPENSATION

The sensor

temperature

compensation of the

device is faulty or was

not carried out. =

possible measuring

error

Maintenance

The device, together with an indication of the

error, must be sent back to the

manufacturer for checking.

OUTPUT NOT

LINEARIZED

Linearization is not

activated = measuring

error

Maintenance

Activate linearization or carry it out again

(HART

®

communication and linearization

software are required; the original

calibration values must be known), or send

the device back to the manufacturer for

linearization.

COUNTER LOST

Totalizer value was

reset by

error/overflow

Warning

Because the reset time is not known:

Controlled reset of the counter using menu

item 1.6.1 or using HART

®

tools/process

control system.

MA_H250_M40_R02_en_640702_PRT.book Page 41 Wednesday, November 28, 2012 12:23 PM