Profibus pa, 2 system configuration of profibus pa network – KROHNE FC 300 Converter PROFIBUS PA-DP User Manual

Page 16

3

PROFIBUS PA

16

IFC 300

www.krohne.com

02/2011 - 4001086601 - AD IFC 300 PROFIBUS R01 en

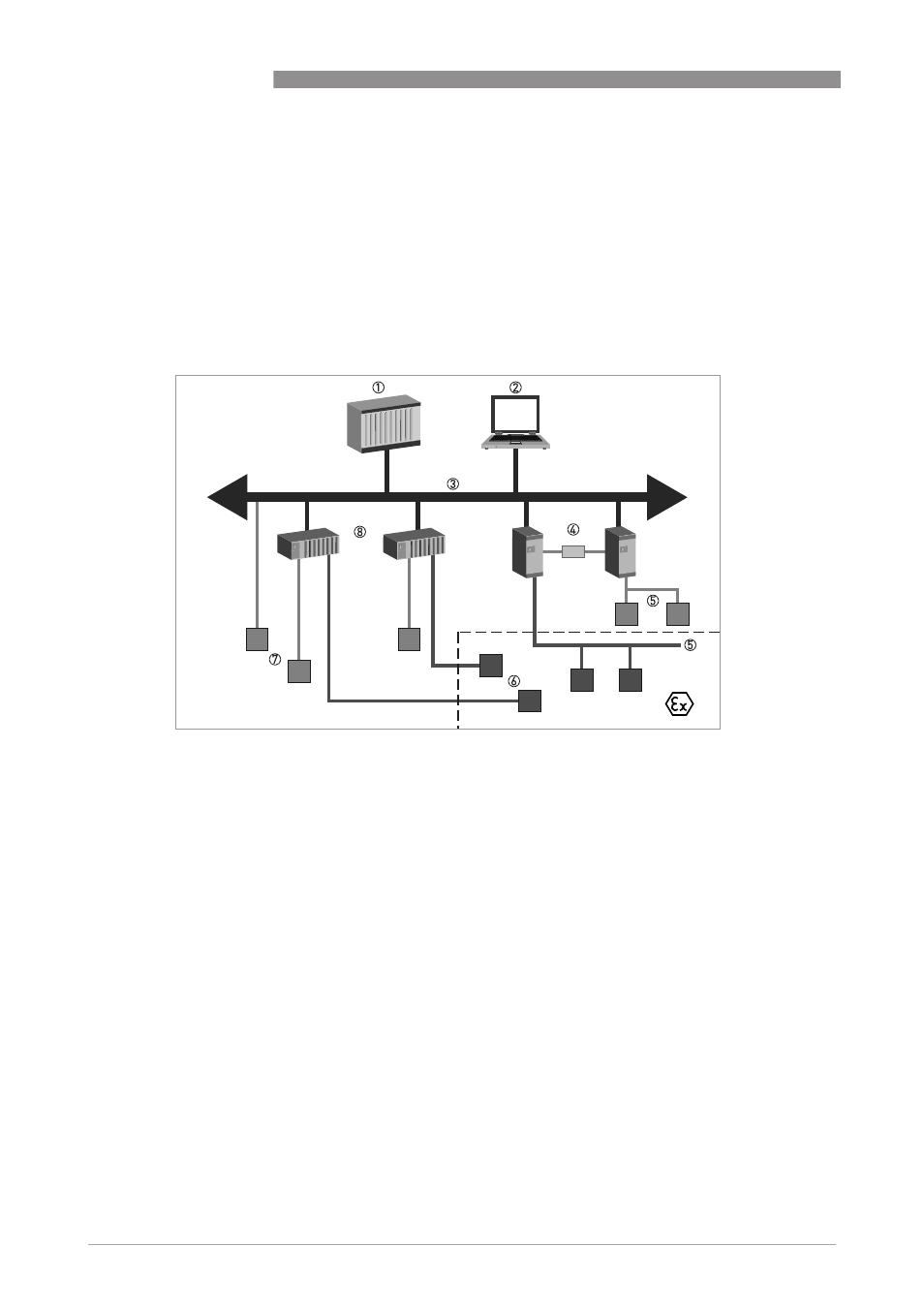

3.2 System configuration of PROFIBUS PA network

The following diagram shows a typical instrumentation with PROFIBUS PA devices with MBP

interface in hazardous and non-hazardous locations, including connections of conventional

devices (e.g. with 4...20 mA signals) in a PROFIBUS network.

As a rule, the PROFIBUS PA segment is connected to a segment coupler which, among other

things, carries out the conversion to the PROFIBUS DP bus line. It should be mentioned that the

segment coupler is normally set to a fixed baud rate on the DP side.

Figure 3-1: PROFIBUS PA network

1 Control system (PLC); class 1 master

2 Engineering or operation control tool; class 2 master

3 PROFIBUS DP network with max. 12 Mbit/s

4 PROFIBUS PA segment coupler DP / PA

5 Device with PROFIBUS PA interface, 31.25 kbit/s

6 HART

®

device

7 More devices with 4…20 mA

8 Analogue I/O module