15 analog programming, 16 operator maintenance, Analog programming -22 – KEPCO EL Series Electronic Load Operator Manual P/N 243-1295 Firmware Version 3.87 to 3.xx User Manual

Page 58: Operator maintenance -22, Analog programming control voltage scale -22, 16 f

3-22

SERIES EL 022013

rise-time transients. The sudden change in current causes the battery plates to warp

slightly, thus changing capacitance which interacts with the inductance of the cables.

3.15

ANALOG PROGRAMMING

The Analog PGM input is summed with the digital setpoint value. Applying a positive voltage to

the Analog PGM input increases the digitally determined setpoint, and applying a negative volt-

age to the Analog PGM input decreases the digitally determined setpoint.

Because the analog signal is summed with the digital setpoint, it must produce a result that is

either 0 or positive, since the load can not control current in the negative direction.

For example, for the EL 5K-400-400 in CI Mode, if the digital setpoint is zero, a 0 to10V signal

applied to the PGM input adjusts the controlled parameter (current) from 0 to full scale (400A).

However, if the digital setpoint is set to 200A, ±5V applied to the Analog PGM input allows cur-

rent from 0A (-5V) to 400A (+5V).

The effect of the analog signal varies depending on mode selected (limited to CI, CP or CV) and

the range (see Table 3-3).

For Master/Slave configurations, the analog programming signal must be simultaneously

applied to all parallel-connected units.

3.16

OPERATOR MAINTENANCE

No scheduled maintenance is required, other than to keep the high current connections tight

and to ensure all airways are clear of obstructions that could cause the load to overheat during

operation at higher power. Calibration Verification should be performed yearly or as required.

The exterior of the load should be cleaned periodically, as is necessary, using a soft cloth damp-

ened with a mild, non-abrasive, water-soluble detergent, and then rinsed with a water-damp-

ened soft cloth.

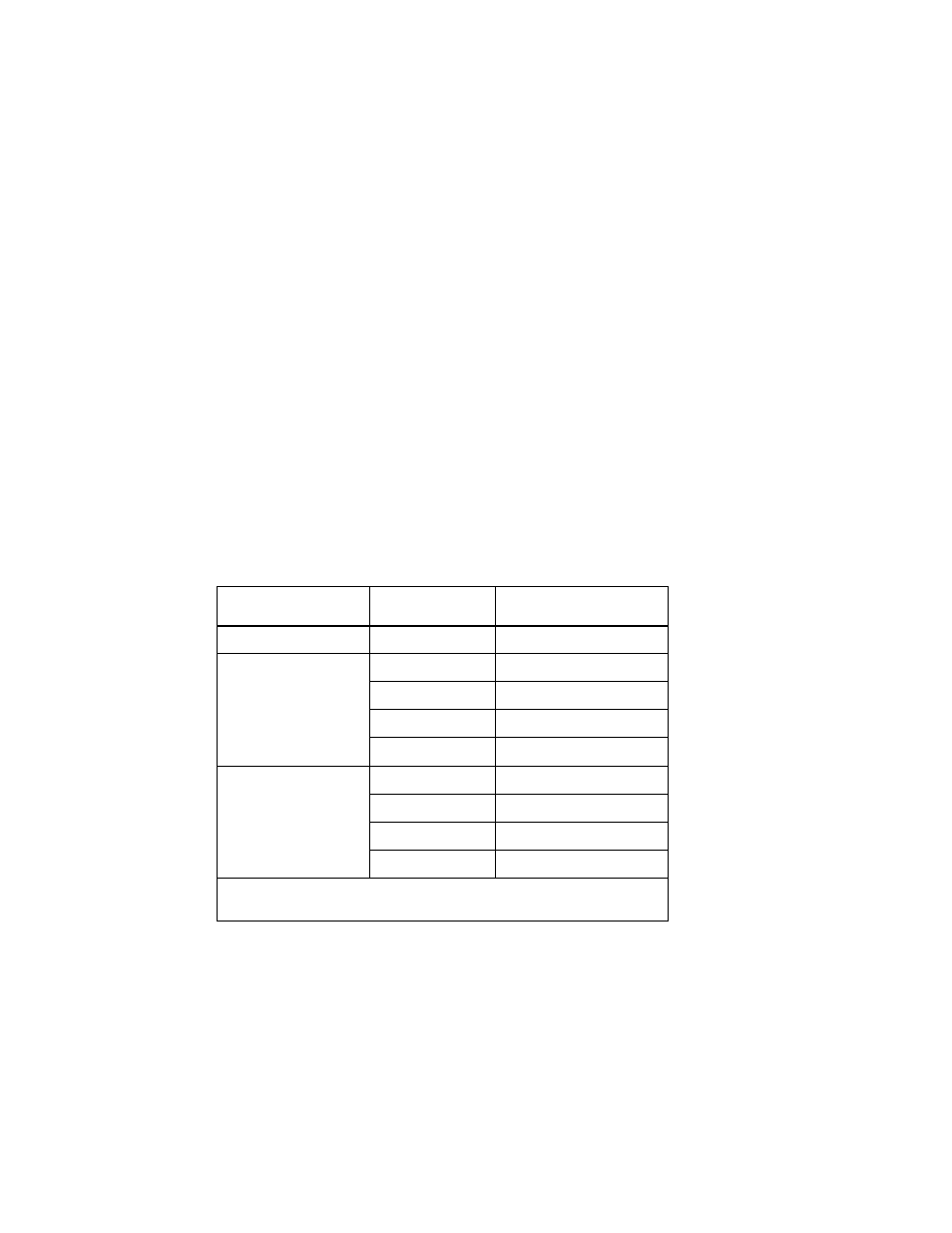

TABLE 3-3. ANALOG PROGRAMMING CONTROL VOLTAGE SCALE

MODE

RANGE

(SEE NOTE)

ANALOG CONTROL

Constant Current (CI)

Not Applicable

60 Amperes/Volt

Constant

Power

(CP)

100 Volts

6 KWatts/Volt

200 Volts

12 KWatts/Volt

400 Volts

24 KWatts/Volt

800 Volts

48 KWatts/Volt

Constant

Voltage

(CV)

100 Volts

10 Volts/Volt

200 Volts

20 Volts/Volt

400 Volts

40 Volts/Volt

800 Volts

80 Volts/Volt

NOTE: Default voltage measurement setting for CP and CV mode is auto-

range. Use SCPI commands to change ranges (see APPENDIX B).