Combustion air and vent system requirements – A.O. Smith 12 40GPC T 100 User Manual

Page 9

9

COMBUSTION AIR AND VENT SYSTEM REQUIREMENTS

Vent Connectors:

1. Type B, Double wall, U.L. Listed Vent Pipe.

2. Single wall Vent Pipe.

Maintain the manufacturer’s specifi ed minimum

clearance from combustible materials when using

type B double wall vent pipe.

Vent connectors made of type B, double wall

vent pipe material may pass through walls or

partitions constructed of combustible material if

the minimum listed clearance is maintained.

Maintain a one inch minimum clearance from all

combustible materials when using single wall vent

pipe.

IMPORTANT: Single wall vent pipe cannot be

used for water heaters located in attics and may

not pass through attic spaces, crawl spaces or

any confi ned or inaccessible location. A single wall

metal vent connector cannot pass through any

interior wall.

When installing a vent connector, please note the

following

• Install the vent connector avoiding

unnecessary bends, which create resistance

to the flow of vent gases.

• Install without dips or sags with an upward

slope of at least 1/4-inch per foot.

• Joints must be fastened by sheet metal

screws or other approved means. It must be

supported to maintain clearances and prevent

separation of joints and damage.

• The length of the vent connector cannot

exceed 75% of the vertical vent height.

• The vent connector must be accessible for

cleaning, inspection, and replacement.

• Vent connectors cannot pass through any

ceiling, floor, firewall, or fire partition.

• It is recommended (but not mandatory) that

a minimum 12 inches of vertical vent pipe be

installed on the draft hood prior to any elbow

in the vent system.

IMPORTANT: Existing vent systems must be

inspected for obstructions, corrosion, and proper

installation.

Chimney Connection: IMPORTANT: Before

connecting a gas vent to a chimney, make sure

the chimney passageway is clear and free of

obstructions. The chimney must be cleaned if

previously used for venting solid fuel appliances

or fireplaces. Also consult local and state codes

for proper chimney sizing and application or, in the

absence of local and state codes, the “National Fuel

Gas Code”, ANSI Z223.1(NFPA 54)-current edition.

• The connector must be installed above the

extreme bottom of the chimney to prevent

potentially blocking the flue gases.

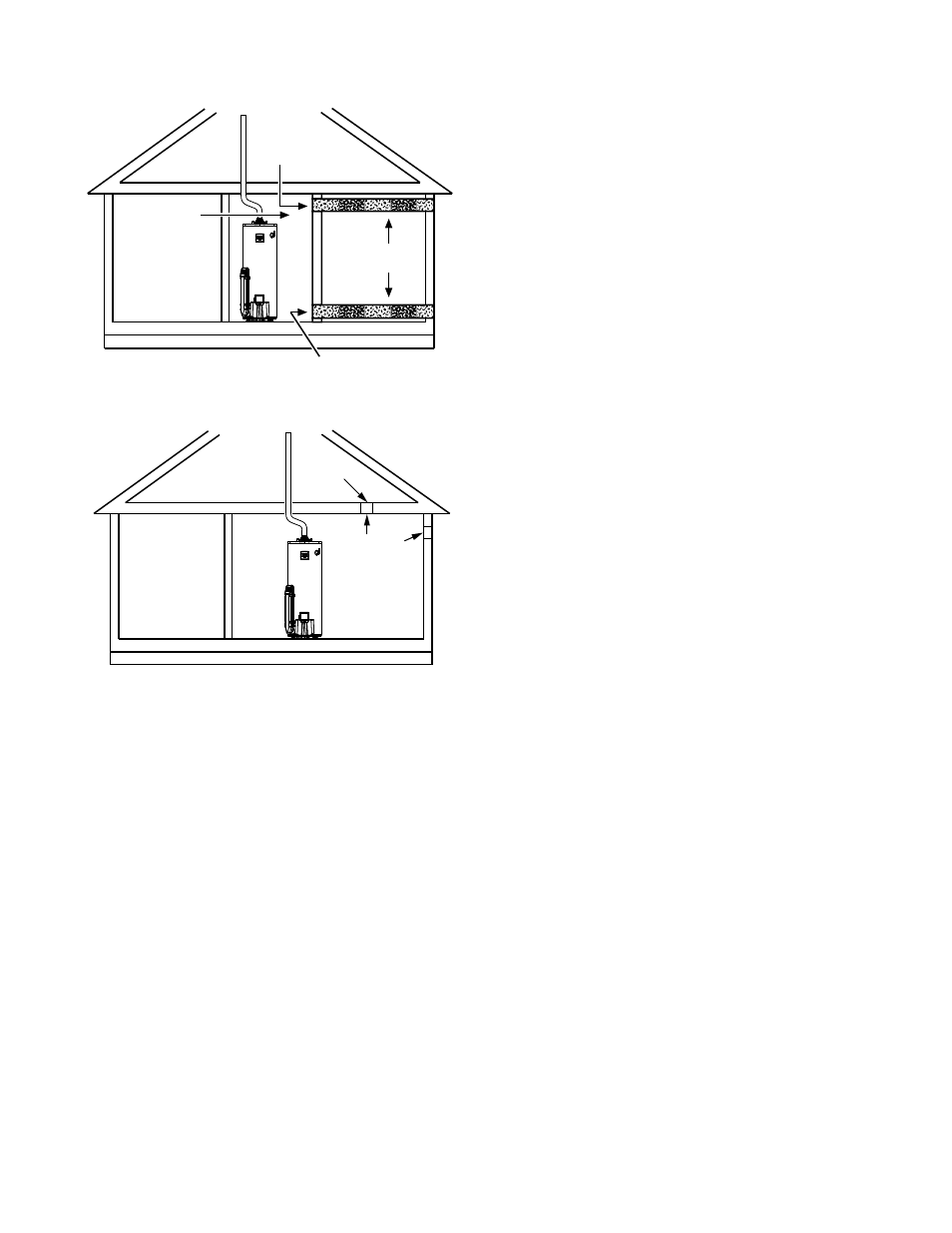

Figure 6.

Figure 7.

Vent Pipe System: This water heater must be

properly vented for the removal of exhaust gases

to the outside atmosphere. Correct installation of

the vent pipe system is mandatory for the proper

and effi cient operation of this water heater and is

an important factor in the life of the unit.

The vent pipe must be installed according to all

local and state codes or, in the absence of local

and state codes, the “National Fuel Gas Code”,

ANSI Z223.1(NFPA 54)-current edition. The vent

pipe installation must not be obstructed so as

to prevent the removal of exhaust gases to the

outside atmosphere.

U.L. recognized fuel gas and carbon monoxide

(CO) detectors are recommended in all

applications and should be installed using the

manufacturer’s instructions and local codes, rules,

or regulations.

Vent Pipe Size: It is important that you follow the

guidelines in these instructions for sizing a vent

pipe system. If a transition to a larger vent size is

required, the vent transition connection must be

made at the draft hood outlet. DO NOT reduce

the vent size to less than the draft hood outlet

diameter.

1 SQ. INCH PER

2000 BTUH

100 SQ. INCH

MINIMUM (EACH)

CONFINED

SPACE

1 SQ. INCH PER

2000 BTUH 100 SQ. INCH

MINIMUM (EACH)

INLET

OUTLET

OUTDOOR

AIR DUCTS

ALL AIR FROM OUTDOORS USING HORIZONTAL DUCTS

ALTERNATIVE

OPENING

LOCATION

1 SQ. INCH

PER 3000 BTUH

100 SQ. INCH

MINIMUM (EACH)

CONFINED

SPACE

ALL AIR FROM OUTDOORS - USING A SINGLE PERMANENT OPENING