Installation - mcs-605-1 sensing potentiometer – Warner Electric MCS-208 User Manual

Page 8

8

Warner Electric • 800-825-9050

P-276 • 819-9045

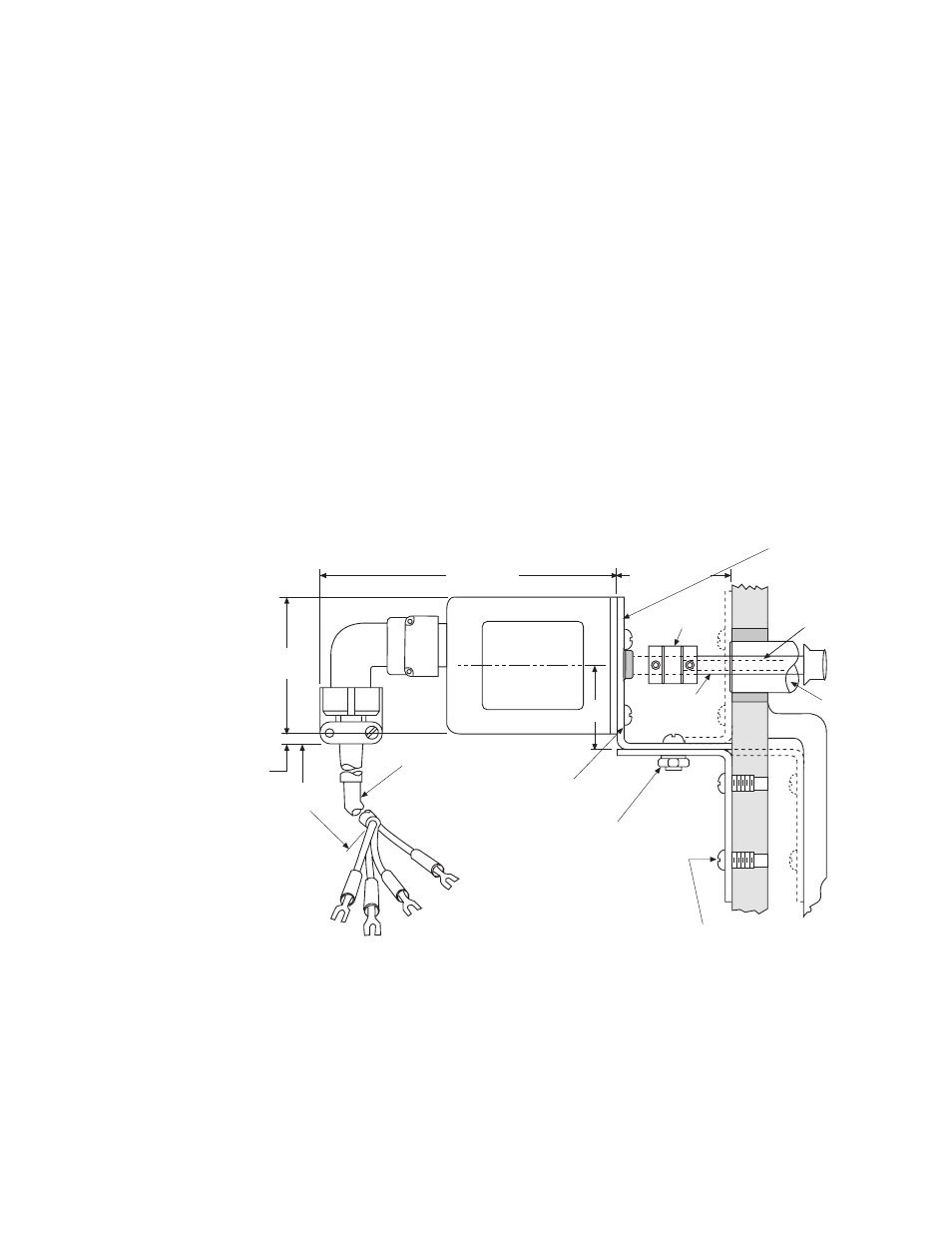

Bracket (see note 1)

.250/.253 Dia.

1/2 Deep

Dancer

Pivot

Shaft

1-11/16 Nom.

Coupling

Supplied

Pin Supplied

8-32 Screws

(3 supplied)

1-1/4

10-32 Screws,

Washers & Nuts

(2 supplied)

3 Holes 3/16 Dia. on

1.50 B.C. Equally

Spaced

NOTES:

1. Two brackets are supplied

with each unit so that the

customer can mount the

MSC-605-1 accordingly.

2. Brackets are made from

14 gauge (.0747) steel.

15' Jacket

5/16

2 Dia.

4-3/8

3. All dimensions are nominal.

Cable

Furnished

Figure 8. MCS-605-1 & TCS-605-5 Mounting Details

Installation - MCS-605-1 Sensing

Potentiometer

1. Using a No. 2 drill, drill a 1/2” deep hole in the

center of the dancer pivot shaft.

2. Drive the supplied pin into the hole in the shaft

until half its length remains exposed.

3. Assemble the two brackets with the two (2)

10-32 screws.

4. Mount the sensor to the brackets using the three

(3) 8-32 screws.

5. Position the sensor and bracket so that the

sensor shaft and pin are aligned and separated

by 5/16".

6. While holding the sensor and bracket in this

position, mark the centers of the bracket holes

on the machine.

7. Drill and tap three (3) holes for 8-32 screws in

the machine.

8. Connect the sensor shaft to the pin with the

universal coupling. The index mark on the

sensor shaft must be aligned with the index

mark on the sensor face when the dancer

arm is at the midpoint position.

9. Mount the sensor and bracket to the machine

with three (3) 8-32 screws.

10. The sensor is now ready to be wired. Refer to

the wiring section starting on page 9 of this

manual for complete wiring instructions.