Warner Electric MCS-208 User Manual

Page 10

10

Warner Electric • 800-825-9050

P-276 • 819-9045

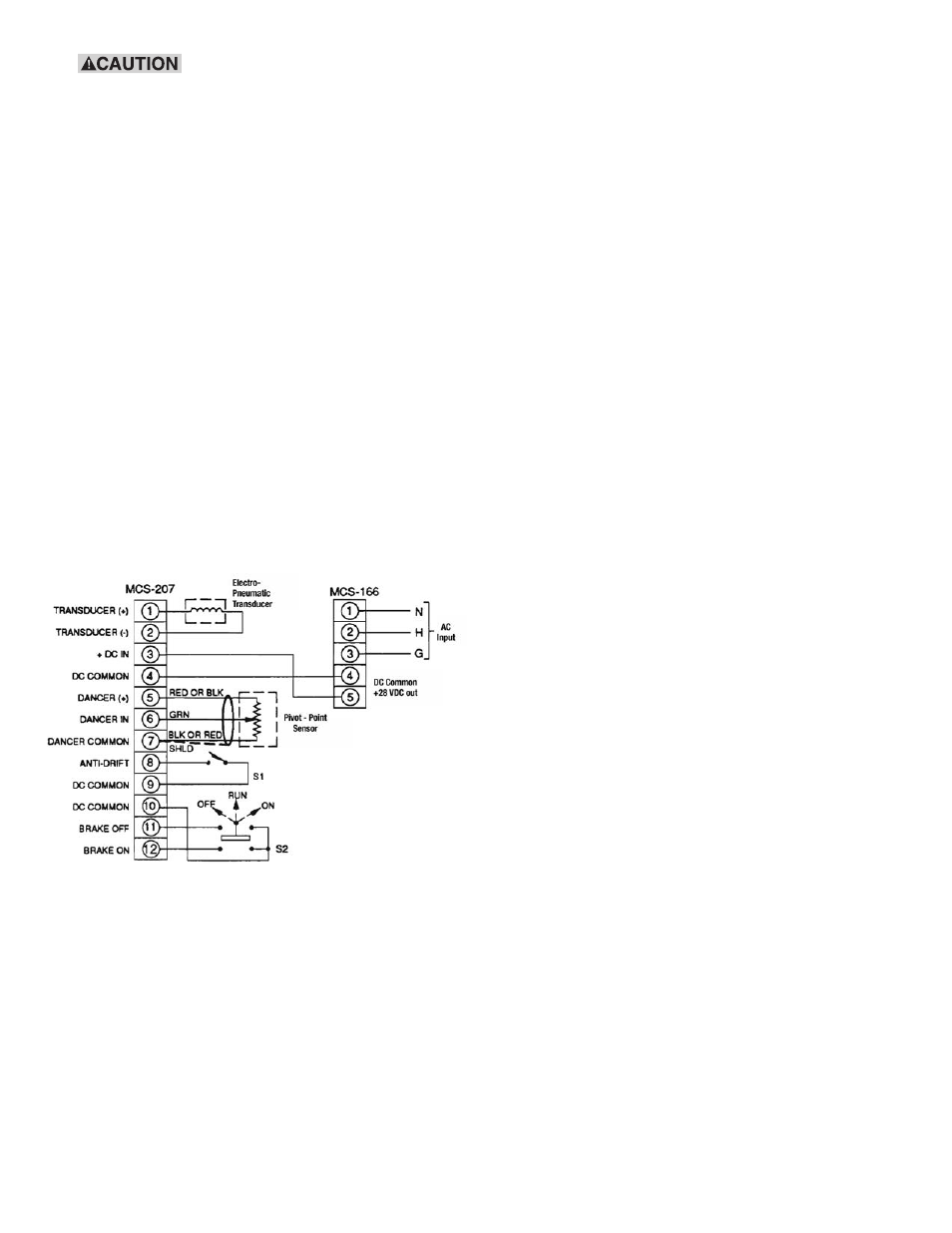

The switch or relay used for the

anti-drift input should be open during normal

running operation to prevent unpredictable

reactions.

b.

Brake-Off Switch

Connect switch contacts between

Terminals 10 and 11 of MCS-207

terminal strip.

c.

Brake-On Switch

Connect switch contacts between

Terminals 10 and 12 of MCS-207

terminal strip.

NoTe: For single brake off function only, use a Single

Pole-Single Throw, maintained contact switch. For both

functions, a three position switch as shown in Figure 9,

page 10, is recommended.

6. Double check all wiring connections per Figure 9.

Insure all terminals are tight.

7. Reconnect the front housing of either wall or shelf

mounting and secure the latches. If shelf

mounting is used, secure the housing with the

four (4) bolts for each section.

8. Do not insert the control modules at this time.

Proceed to the MCS-166/MCS-207 start-up

section of this manual.

MCS-166/MCS-208

Refer to all Figures on pages 11 for actual wiring

connections.

1. Wire AC input to terminals 1, 2 and 3 of the

MCS-166 terminal block: terminal 1 to be AC

neutral, terminal 2 AC hot, and terminal 3 earth

ground.

2. Wire MCS-166 DC output to MCS-208 input:

MCS-166 DC common terminal 4 to MCS-208

DC common terminal 4. MCS-166 (+) DC terminal

5 to MCS-208 (+) input terminal 3.

3. Connect transducer wires to terminals 1 and 2 of

MCS-208 Terminal Block.

4. External Switch Connections (optional)

a.

Brake-Off Switch

Connect switch contacts between

terminals 10 and 11 of MCS-208

terminal strip.

b.

Brake-On Switch

Connect switch contacts between

terminals 10 and 12 of MCS-208

terminal strip.

NoTe: If only a single brake-off function is used, an

SPST maintained contact switch may be used. If both

functions are used, a three position switch is

recommended, as shown in Figure 10, page 11.

5. Control Input Connections

Follow the procedure below (a, b, c, or d) which applies

to the control input mode selected.

Refer to Figure 11, page 12 for various input connection

configurations.

a.

Local Torque Adjust Mode

Connect jumper between MCS-208

terminals 6 and 8, per Figure 11B, page 12.

b.

Remote Torque Adjust/Roll Follower Pot

Connect remote potentiometer or roll

follower potentiometer to MCS-208

terminals 5, 6, and 7, per Figure 11C,

page 12.

NoTe: Wiper will always be connected to terminal 6.

End points should be connected so that turning the

remote pot CCW or moving the roll follower pot toward

the core will decrease voltage at terminal 6.

c.

Voltage Source Input

Connect (+) side of external voltage source

Figure 9. MCS-166/MCS-207 Wiring

Single or Dual Brake