Warner Electric Electric Wheel Brake 12-1_4 x 3-1_2 Replacement User Manual

Page 6

6

Warner Electric • 800-825-9050

819-0209

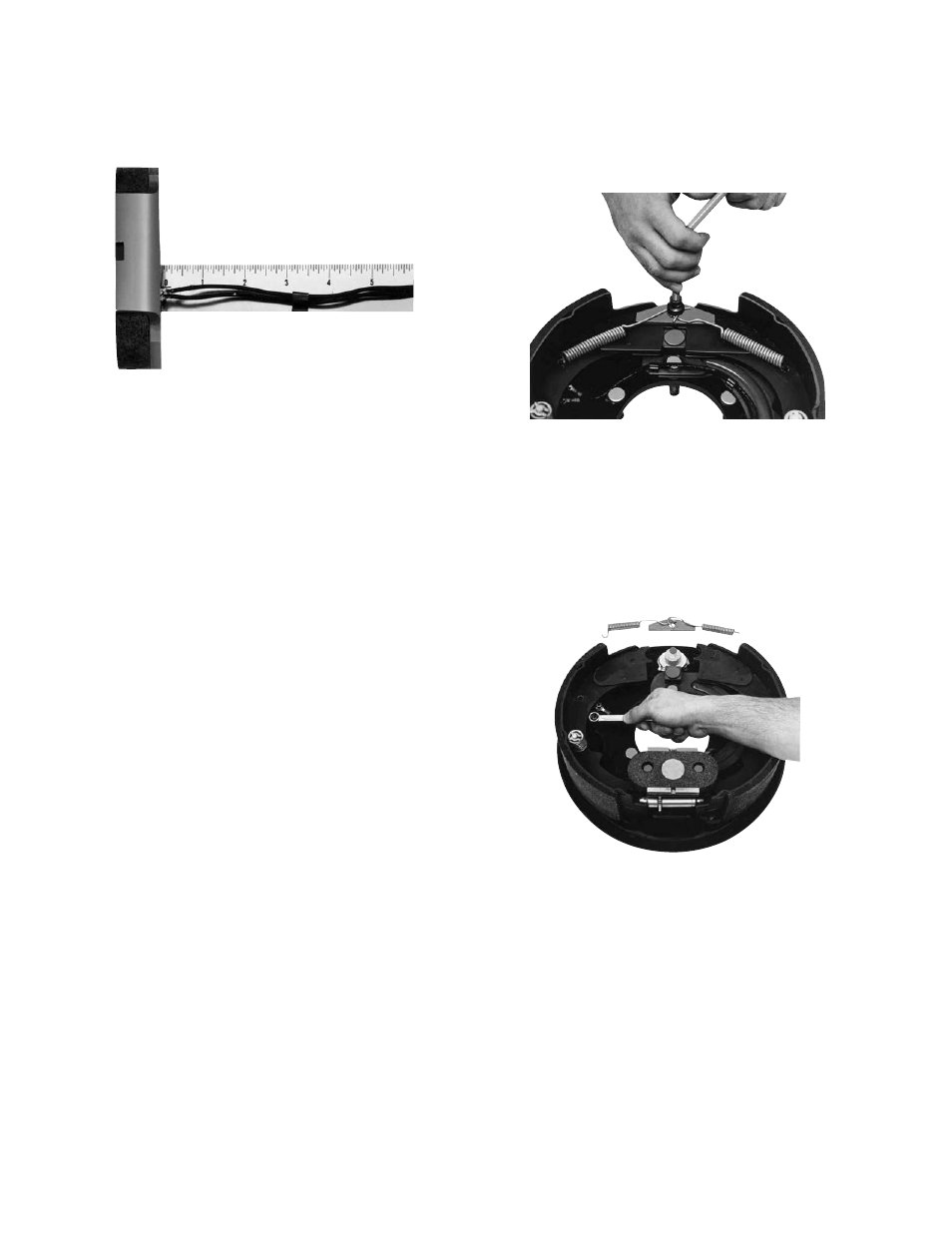

through the five clips on the arm, duplicat-

ing the routing noted in Step 4. (See Figure

8).

On right-hand brakes allow 2-3/8-inches of

wire between the magnet and the first clip.

(See Figure 9).

On-left hand brakes allow 3-1/8-inches of

wire between the magnet and first clip.

(See Figure 10).

Allowing this much wire prevents strain on

the wire when the magnet is pulled out the

maximum distance.

9. Assemble the magnet lead wire terminals

onto the terminal posts (6-3) in the following

sequence.

a. Place one internal lockwasher over each

post.

b. Place one wire terminal over each post.

c. Place one internal nut (6-1) over each post

and tighten them to 30-40 in. lb. torque.

10. Close the shoe (2-1) that was spread to

expose the terminal, and install the anchor

pin plate (4-2).

11. Install the shoe return springs (4-1) using a

brake spring tool.

12. Check to be sure shoes expand and con-

tract properly and are in correct adjust-

ment.

13. Reassemble the drum and wheel. Make

sure wheel bearings and wheel nuts are

adjusted to axle manufacturer’s specifica-

tions.

Case II: Replacing Long-Life Magnet on Old

Style Arm with New Long-Life Magnet

1. Remove the two shoe return springs (4-1),

using a brake spring tool. (See Figure 11).

2. Remove the anchor pin plate (4-2) and

spread the shoe (2-1) apart, exposing the

brake terminal assembly (6).

Figure 12 - Removing Internal Nuts

Figure 10 - L.H. Brakes

Figure 11 - Removing Shoe Return Springs