Warner Electric Electric Wheel Brake 12-1_4 x 3-1_2 Replacement User Manual

Page 19

19

Warner Electric • 800-825-9050

819-0209

On left-hand brakes allow 3-1/8-inches of

wire between magnet and the first clip.

(See Figure 46).

Allowing this much wire prevents strain on

the wires when the magnet is pulled out the

maximum distance.

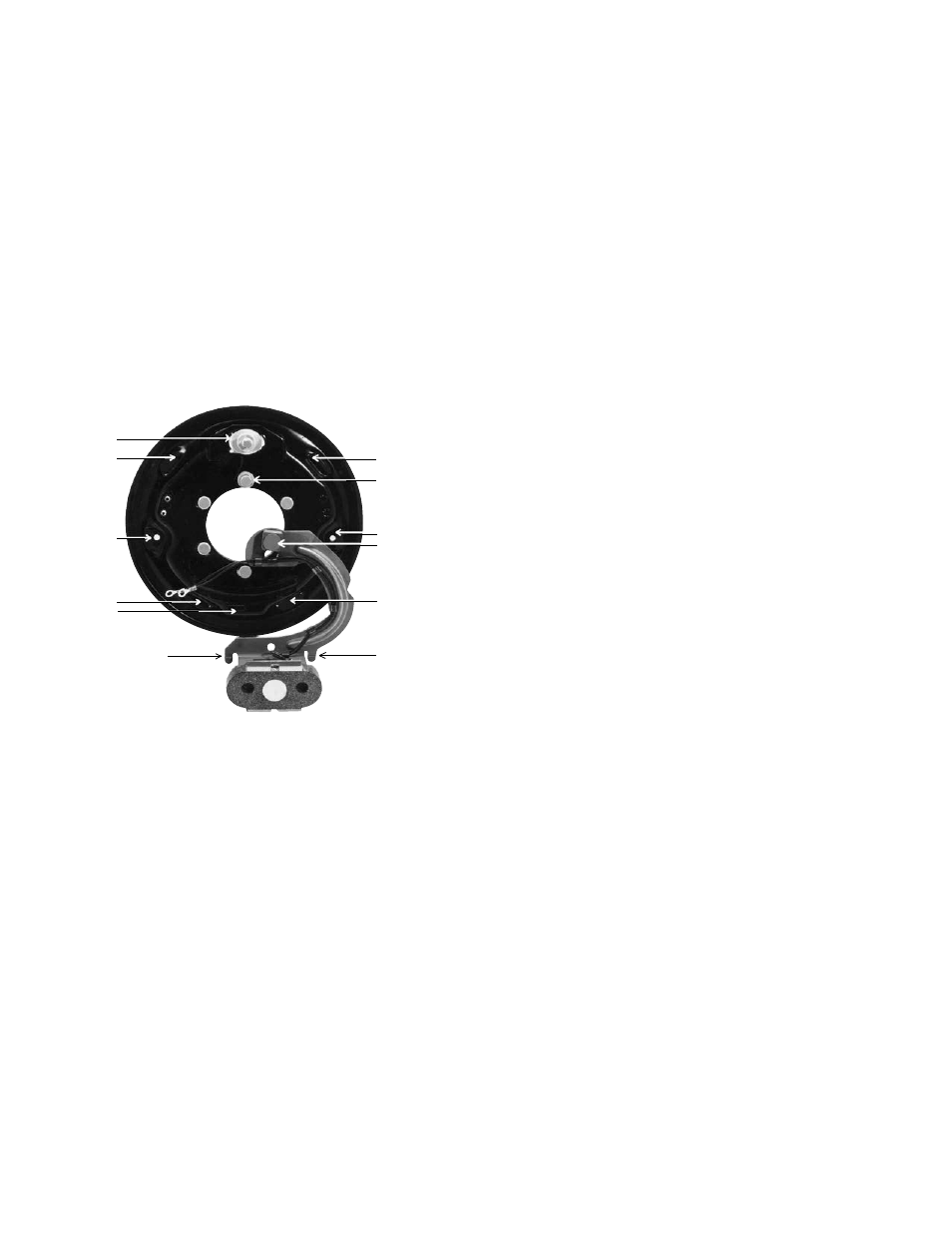

12. Lubricate the following with “moly” impreg-

nated grease:

Lever arm pivot screw (5-2).

Lever arm (5-1)–flat area around pivot

screw bushing, both sides.

Lever arm “feet”, both sides (5-1).

Feet guide area of backing plate.

Six shoe pads on braking plate.

(See Figure 47) “Lubrication Points”

13. Reassemble magnet arm (5-1) over pivot

screw (5-2) making sure magnet arm “feet”

slide in guide on backing plate.

14. Assemble the magnet lead wire terminals

onto the terminal posts (6-3) in the follow-

ing sequence.

a. Place one internal lockwasher over each

post.

b. Place one wire terminal over each post.

c. Place one internal nut (6-1) over each post

and tighten them to 30-40 in. lb. torque.

15. Reinstall the two shoes (2-1); the adjuster (3-

1, 3-2, and 3-3) and the adjuster spring (3-5)

as a complete assembly.

16. To facilitate the installation of the shoe hold

down assemblies, rotate either shoe (2-1)

away from the anchor pin so that the shoe

slides off the shoe pad and onto the curl of

the backing plate. This procedure will mini-

mize the hold down spring compression

required.

17. As noted in Step 3, there are two shoe hold

down assembly configurations. Follow the

instructions for Style A or Style B to install

the shoe hold down assemblies.

Style A (old style): Insert the pin (with the

rubber washer on its head) through the rear

of the backing plate and through the hole in

the shoe web.

Place a dished washer, the spring, and

another dished washer over the pin end.

Compress the spring assembly below the

swaged end of the pin. Rotate the top washer

90° to lock the assembly into place.

Repeat these steps for the second shoe hold

down assembly.

Style B (new style): Insert a hold down pin

(2-3) through the hole in the rear of the

backing plate and through the hole in the

shoe web (2-1). Hold the pin in place.

Place a spring cup (2-4), convex upward,

over the pin. Next install the spring (2-2), a

spring cup (2-4) convex downward, and then

a spherical washer (2-5) over the protruding

pin (2-3). The spherical washer nests in the

spring cup.

Slide a new “X” washer retainer (2-6) between

the head of the pin (2-3) and the spherical

Figure 47 - Lubrication Points