Warner Electric Electric Wheel Brake 12-1_4 x 3-1_2 Replacement User Manual

Page 12

12

Warner Electric • 800-825-9050

819-0209

5. Note: This step pertains only to brakes

using Style “A” shoe hold down assem-

blies.

Discard all old pins, rubber washers, spring

cups, and old springs. Drill out the two hold

down pin clearance holes in the backing

plate with a 5/16-inch (.312-inch) dia. drill.

6. Lubricate the six shoe pads on the backing

plate with “moly” impregnated grease. (See

Figure 26).

7. Assemble the two new shoes (2-1), adjuster

spring (3-5), and adjuster (3-1, 3-2, and 3-

3). Make sure the adjuster is fitted into the

notches in the shoe web. Install the assem-

bly onto the brake. (See Figure 27).

8.

To facilitate the installation of the new style

shoe hold down assemblies, rotate either

shoe (2-1) away from the anchor pin so that

the shoe slides off the shoe pad and onto

the curl of the backing plate. This proce-

dure will minimize the hold down spring

compression required.

9.

Insert a hold down pin (2-3) through the

hole in the rear of the backing plate and the

hole in the shoe (2-1) web. Hold pin in

place.

10. Place a spring cup (2-4), convex upward,

over the pin. Next install the spring (2-2), a

spring cub (2-4) (convex downward), and

then a spherical washer (2-5) (it nests in the

spring cup) over the protruding pin (2-3).

11. Slide a new “X” washer retainer (2-6)

between the head of the pin (2-3) and the

spherical washer (2-5) while compressing

the assembly. Using pliers, close the “X”

washer retainer to lock on the pin.

12. Lift the shoe (2-1) onto the shoe pads on

the backing plate with a heavy screwdriver.

Rotate it into the place against the anchor

pin.

13. Repeat Steps 8 through 12 for the second

shoe hold down assembly.

14. Install the anchor pin plate (4-2).

15. Install the shoe return springs (4-1), using a

brake spring tool.

16. Check that the shoes expand and contract

properly. Set the shoes to the fully con-

tracted position before installing the drums.

17. Reassemble the drums and wheels. Make

sure the wheel bearings and wheel nuts are

adjusted to the axle manufacturer’s specifi-

cations.

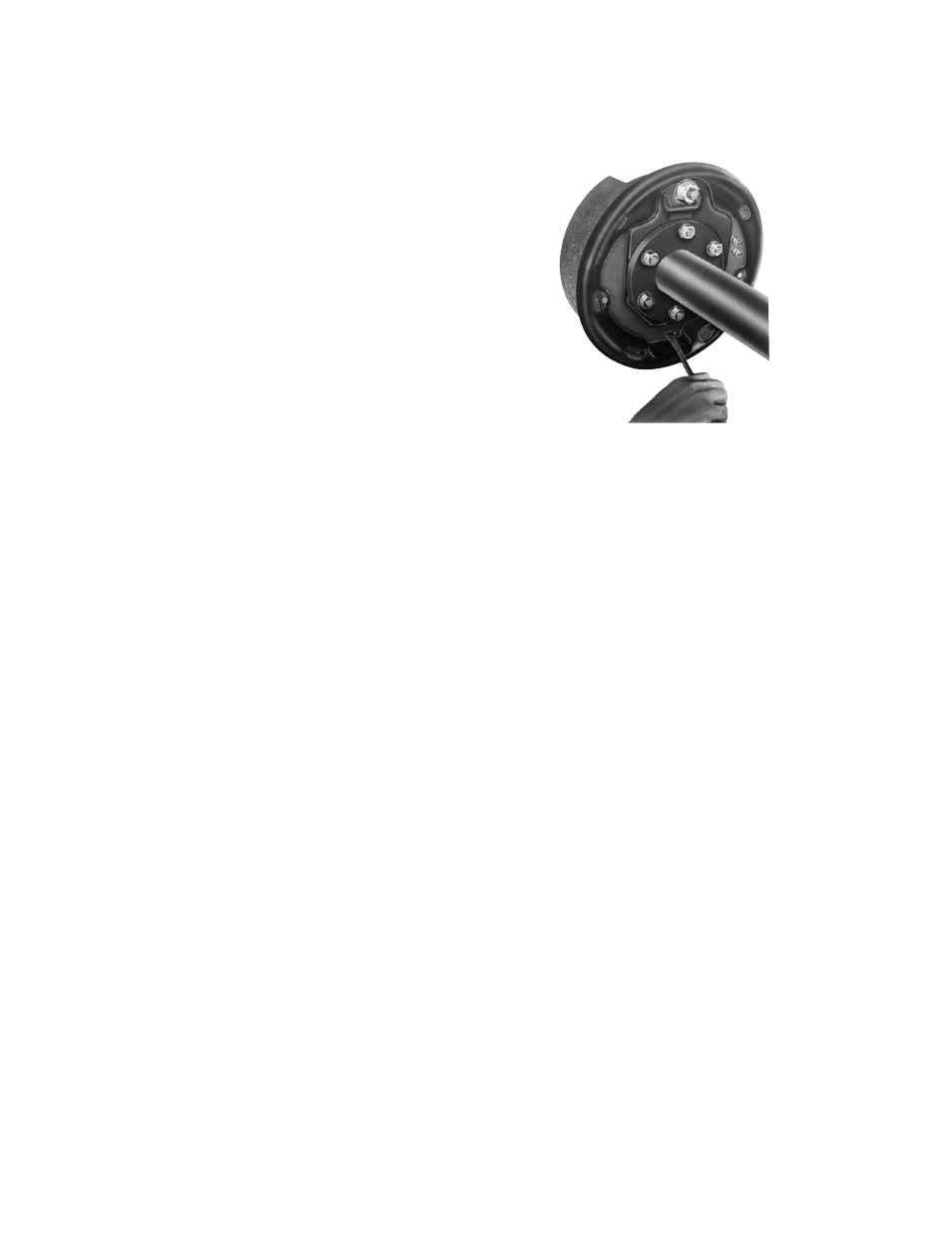

18. Brake Adjustment: Remove the rubber

adjuster plug (3-4) and insert an adjusting

tool. (See Figure 28).

With the wheel off the ground, expand the

shoes until the brake drags significantly.

(Upward motion of the tool turns the

adjusting nut, 3-3, to expand the shoes

against the drum.)

Then back off the adjuster (downward

motion) until the wheel turns freely, usually

10 to 12 notches.

After the initial 500 miles of operation

(when the new shoes and drum have been

seated), brake readjustment is recommend-

ed.

Figure 28 - Brake Adjustment