Warner Electric ER-1225 User Manual

Page 5

Warner Electric • 800-825-9050

819-0466 5

Tools required (not included)

- 1/4” Hex key wrench for taper lock bushing

set screws - ER-1225 .

- 3/16” Hex key wrench for taper lock bushing

set screws - ER-825 .

- 7/32” Hex key wrench for mounting screws .

- Grade 242 Loctite .

- Snap ring pliers, external .

- Torque wrench minimum 200 lb .ft . reading -

ER-825 .

- Torque wrench minimum 400 lb .ft . reading -

ER-1225 .

- 3 steel shims, equal thickness, not less than

1/16”, not greater than 1/8” .

- Small hammer (approximately 8 ounce) .

- Brass Drift .

- Flat blade screwdriver .

- Loctite grade 242 .

INSTALLATION FOR ER-825

BRAKE WITH OUTSIDE

ARMATURE HUB

Technical Information:

Static Torque: . . . . . . . . . . . . . . . . . 125 lb .ft .

Max RPM: . . . . . . . . . . . . . . . . . . . . . . . . . 3600

Voltage: . . . . . . . . . . . . . . . . . . . . . . . . . 90 VDC

Total weight: . . . . . . . . . . . . . . . . . . . . . . 15 .6 lb .

Current draw - Nominal: . . 0 .295 amp @ 90 Volts

Resistance at 20 degrees C: .305 ohms ±10%

Step 1: Remove the ER brake from its shipping

carton . The carton contains a magnet

(Item 11) and armature (Item 3) plus

mounting hardware and a conduit box .

(See Figure 1) Inspect the components to

make sure they have not been damaged

in shipping .

Step 2: Wipe the magnet and its mounting

surface clean and remove any burrs .

No solvents on friction face!

Step 3: Assemble the conduit box to the magnet

in accordance with the instructions

furnished with the conduit box .

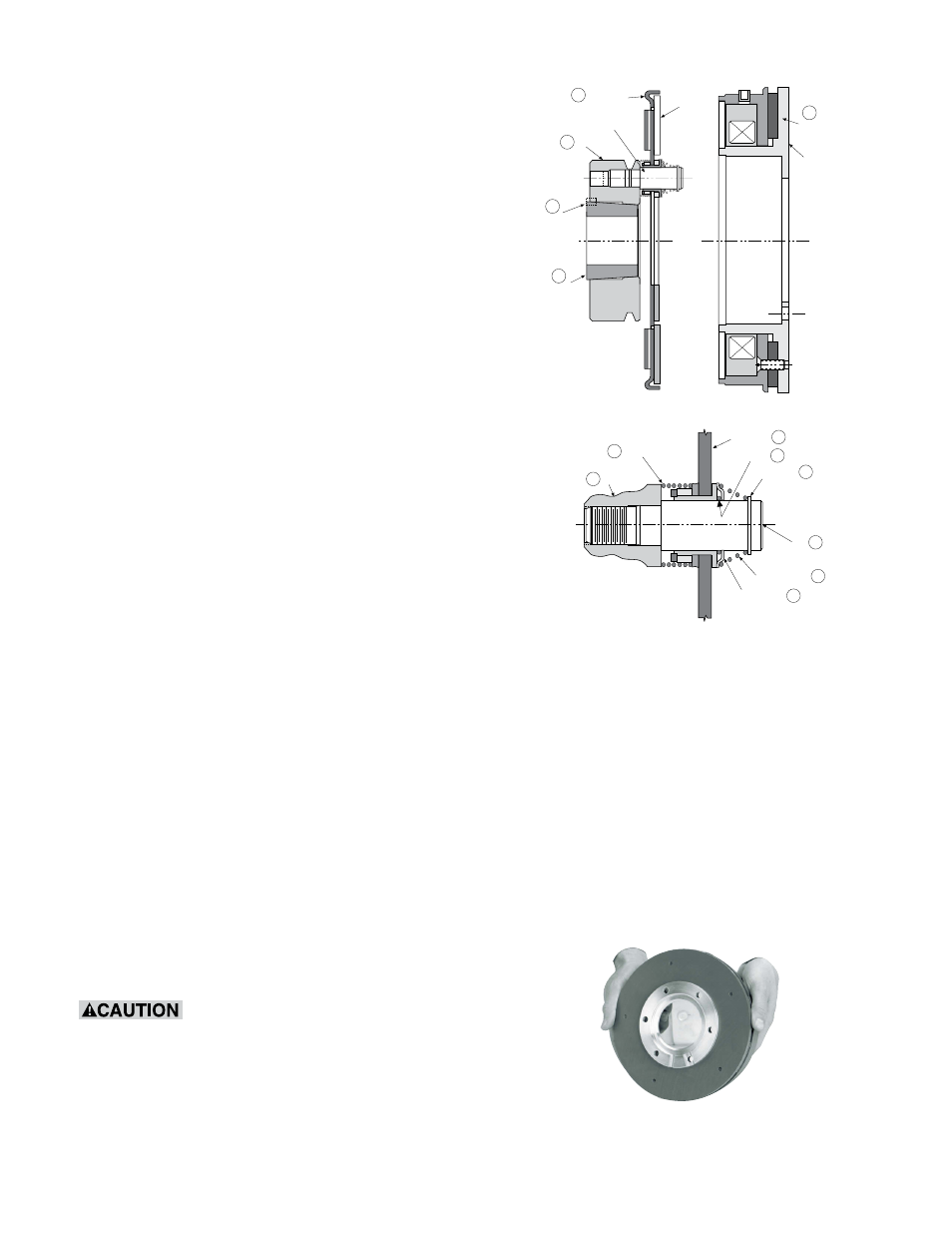

Detail A

Hub

6

Red Spring

Retainer

Ring

Pin

Armature

Yellow Spring

Detent

Detent Cup

8

10

4

3

5

2

7

Magnet

11

1

Set Screw

12

See Detail A

Hub

Armature

3

2

Taperlock

Bushing

Working

Surface

Mounting

Surface

Figure 1

Assembled brake shown numbered components.

Item numbers shown will be referenced

throughout this installation procedure.

Step 4: Insert an aluminum (or other non-

magnetic material) spacer into the

magnet bore and align the holes in both

components .

This spacer must be machined to pilot on

the motor and magnet pilot mounts and

align within the tolerances specified in the

introduction to this manual. (See Figure 2)

Figure 2 - Aluminum spacer installed