Warner Electric ER-1225 User Manual

Page 12

12 Warner Electric • 800-825-9050

819-0466

Step 4: Position the magnet/spacer assembly

on the transmission pilot and align the

holes in the magnet with the spacer

and mounting surface holes . Following

the manufacturer’s instructions, apply

grade 242 Loctite to the threads of

each furnished cap screw, add a lock

washer, and fasten the magnet on the

transmission . Tighten these screws to 25

to 28 lb .ft . torque with a torque wrench .

Make the elecrical connection . The positive and

negative of the power lead must be connected to

the positive and negative lead wires or terminals

of the brake, respectively . follow KONE Inc .

instructions to set the release voltage of the brake .

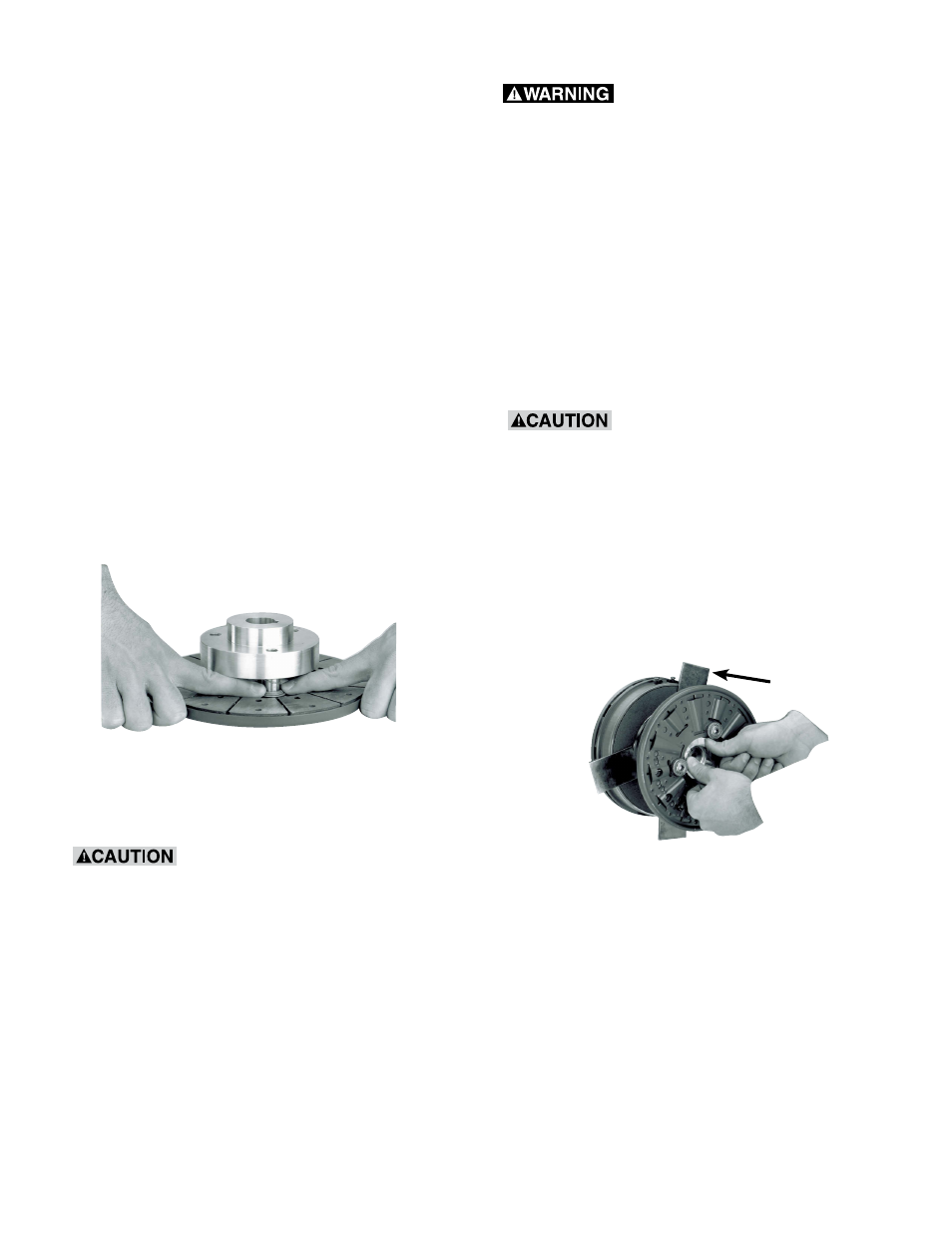

Step 5: Place the armature hub assembly on a

flat surface with the armature working

face up . Push down on each detent cup

(Item 5) with your fingers, pushing the

armature down until the armature will not

move down any further . (See Figure 15)

Figure 15 - Positioning the detent cups

in the armature.

During steps 7 and 8, handle the

armature/hub assembly by the hub (Item 1)

only, making sure the armature (Item 2) is as

close to the retainer ring (Item 9) as possible.

Any movement of the armature on the pins

(Item 3) will reduce available armature travel

and may cause improper air gap setting.

Keep fingers clear of the area

between the magnet (Item 10) and the

armature (Item 2) because the armature

will be pulled sharply toward the magnet

after the gap is closed to approximately 1/8

inch. Injury can result if fingers are pinched

between the armature and the magnet.

Step 6: Insert the key in the motor shaft key way .

Step 7: Make sure no power is applied to

the brake. Place three steel shims 120

degrees apart on the magnet as shown

in Figure 16 .

.062 inch shims are

recommended. Do not use shims thicker than

.125 inch or you will shorten brake life by

reducing available armature travel.

Slip the armature/hub assembly onto the

transmission shaft until the armature hub bottoms

out on the shims . (See Figure 16) The gap

between the armature & magnet must be no more

than .125 inch . If the gap is larger than .125 inch,

push on the hub to achieve .125 inch gap .

Shims

Figure 16 - Armature installation

with shims in place.

Step 8: Insert the washer and bolt into the

threaded hole in the end of the shaft .

Tighten the bolt to the torque specified

by KONE Inc . .