Warner Electric ER-1225 User Manual

Page 3

Warner Electric • 800-825-9050

819-0466 3

This ampere turn value can vary among brakes

because of allowable manufacturing tolerances .

Release voltage varies mainly because of the

coil tolerance and Autogap® spring variations .

Properly adjusting the power supply voltage is

important so the autogap springs will separate the

magnet and armature, causing full release . If the

release voltage is not set properly, the armature

will rub against the magnet . This rubbing action

can cause the brake and other components in the

system to fail . Warner Electric Electrically Released

Brakes are burnished at the factory to assure

rated torque shortly after initial application . Very

little additional wear-in is required .

Introduction

Warner Electric Electrically Released Brakes

function on the same principle of “response to

magnetic attraction” that operates other Warner

Electric brakes and clutches . Braking torque in

the Electrically Released Brake depends on

permanent magnets rather than electromagnets .

With the power off, the unit produces full braking

torque . The brake is released by reversing the

direction of flux flow in an electromagnetic coil,

thus opposing the field produced by the

permanent magnets .

The cancellation of electromagnetic force which

releases the brake occurs at one nominal value

of ampere turns .

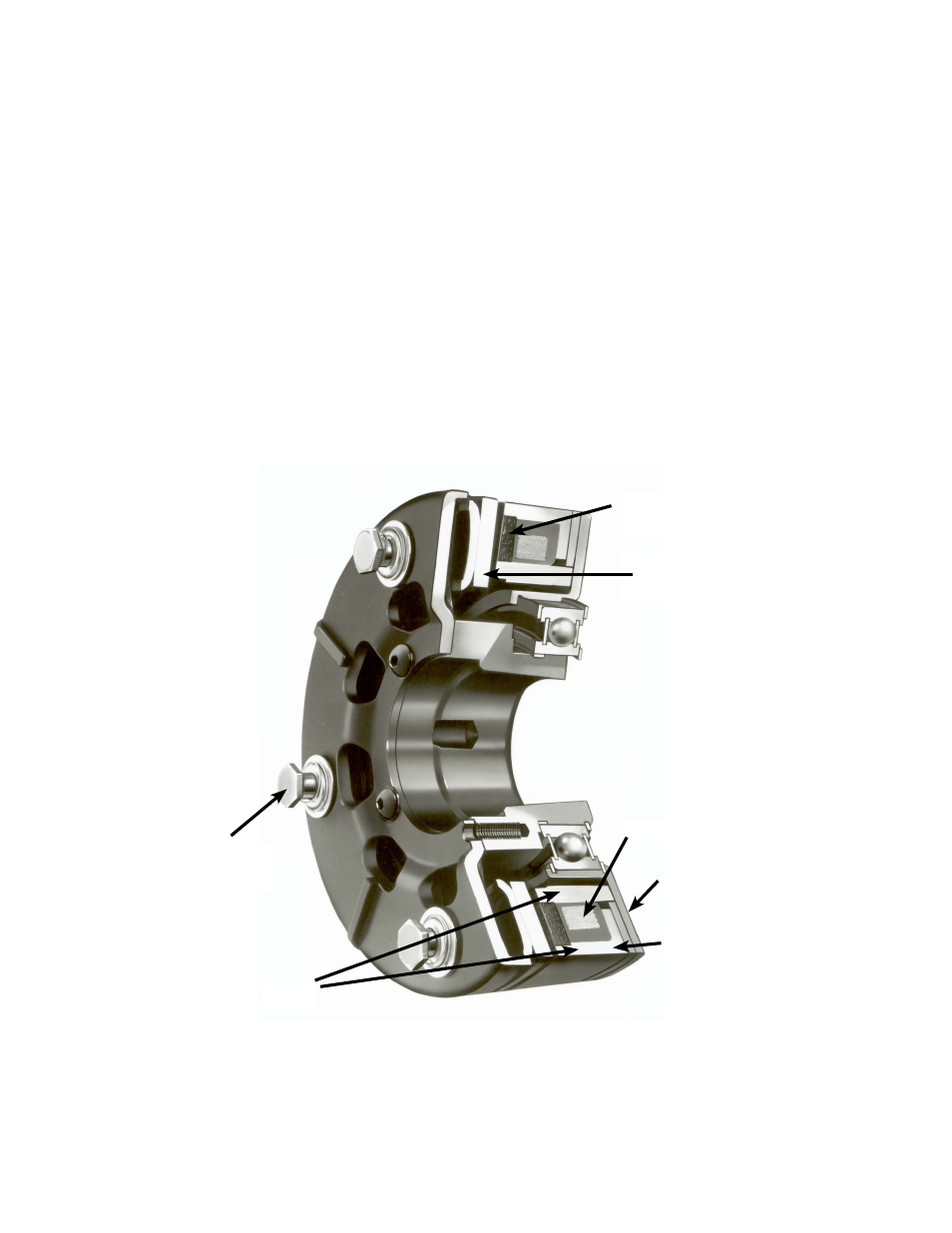

The same principle of “response to magnetic attraction” used in this FB-650 operates the larger ER-825

and ER-1225 Electrically Released Brakes Described in this manual

Autogap®

Assembly

Poles

Friction

Material

Armature

Coil

Permanent

Magnets

Magnet

Shell